Automatic chain-type solid-state fermentation reaction device and method of automatic solid-state fermentation thereof

A solid-state fermentation and reaction device technology, applied in the field of fermentation industry, can solve the problems of poor consistency of fermentation level, heavy labor, cumbersome solid-state fermentation operation, etc., and achieve the effect of fermentation production, continuous fermentation production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

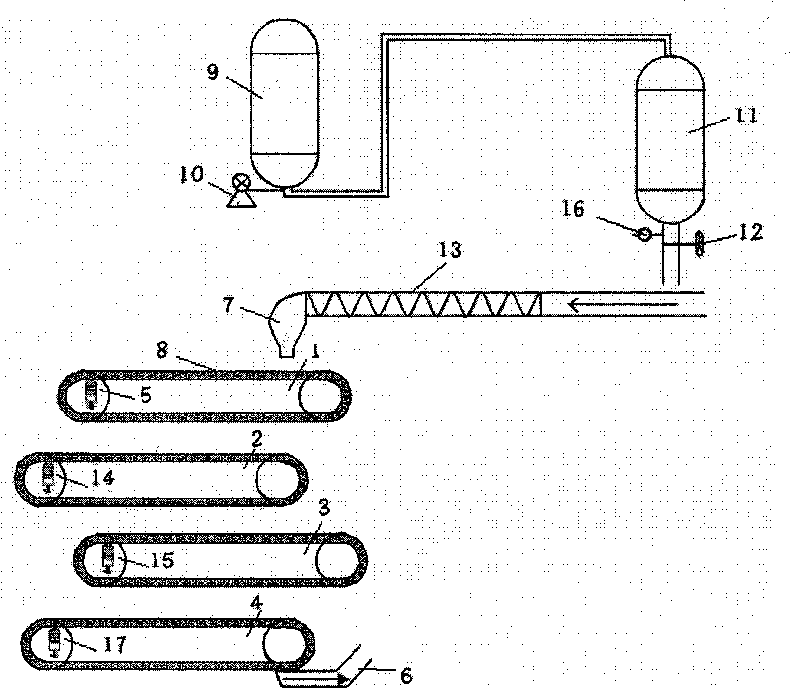

[0035] exist figure 1 The shown automatic chain-belt solid-state fermentation reaction device automatically produces fermented soybean meal.

[0036] Incline strains: Weigh 1200g of potatoes, 120g of glucose, 30g of NaCl and 120g of agar, add 6000mL of water, sterilize at 0.12MPa for 20min, and use one or more of Candida utilis, Schwannoma and Candida tropicalis After inoculating the strains, culture them at 30°C for 24 hours to obtain the strains on the slant.

[0037] Liquid strains: Weigh 1200g of potatoes, 120g of glucose and 30g of NaCl, add 6000mL of water, sterilize at 0.12MPa for 20min, and inoculate with the above slanted strains to obtain liquid strains.

[0038] Weigh 1200g of potatoes, 120g of glucose and 30g of NaCl and put them in the fermenter 9, add 6000mL of water, sterilize at 0.12MPa for 20min, inoculate with the above-mentioned liquid bacteria, and incubate at 30°C for 24h to obtain the seed liquid.

[0039] Weigh 10,000 kg of soybean meal, place it in a ...

Embodiment 2

[0046] exist figure 1 The shown automatic chain-belt solid-state fermentation reaction device automatically produces fermented feed.

[0047] Incline strains: Weigh 1200g of potatoes, 120g of glucose, 30g of NaCl and 120g of agar, add 6000mL of water, sterilize at 0.12MPa for 20min, and use one or more of Candida utilis, Schwannoma and Candida tropicalis After inoculating the strains, culture them at 30°C for 24 hours to obtain the strains on the slant.

[0048] Liquid strains: Weigh 1200g of potatoes, 120g of glucose and 30g of NaCl, add 6000mL of water, sterilize at 0.12MPa for 20min, and inoculate with the above slanted strains to obtain liquid strains.

[0049] Weigh 1200g of potatoes, 120g of glucose and 30g of NaCl and place them in a fermenter, add 6000mL of water, sterilize at 0.12MPa for 20min, inoculate with the above-mentioned liquid bacteria, and incubate at 30°C for 24h to obtain the seed liquid.

[0050] Weigh 6,000 kg of soybean meal and 4,000 kg of bran, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com