Method for preparing high alumina castable without being moistened by aluminum liquid

A high-aluminum castable and molten aluminum technology, applied in the field of refractory castables, can solve problems such as insufficient homogenization, inability to completely and effectively solve the wetting problem, increase penetration resistance, and improve non-wetting by molten aluminum. , The effect of improving the penetration and corrosion resistance of molten aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

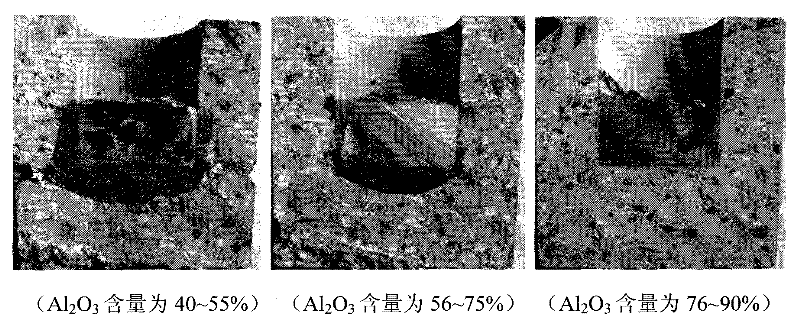

[0022] A kind of preparation method of high-alumina castable that is not wetted by aluminum liquid prepares Al 2 o 3 A refractory castable with a content of 40-55%. The composition of the castable is 63wt% of burnt sapphire particles, 16wt% of burnt sapphire fine powder, 5wt% of silicon oxide micropowder, 6wt% of anti-aluminum liquid wetting agent (BaSO 4 4.8wt%, Na 3 AlF 6 1.2wt%), pure calcium aluminate cement 10wt%, plus 0.15% sodium tripolyphosphate, plus 0.05wt% sodium hexametaphosphate. First, burnt gemstone fine powder, BaSO 4 and Na 3 AlF 6 16wt%: 4.8wt%: 1.2wt% were co-milled and homogenized for 25 minutes, and then the co-milled homogenized material was pressed as coke gem powder, BaSO 4 and Na 3 AlF 6 The proportion shared in the castable and other components in the castable are uniformly mixed with a forced mixer, that is, a high-alumina castable that is not wetted by the aluminum liquid is prepared.

[0023] The pouring material of the present invention ...

Embodiment 2

[0025] A kind of preparation method of high-alumina castable that is not wetted by aluminum liquid prepares Al 2 o 3 A refractory castable with a content of 40-55%. The composition of castable is 64wt% of tertiary bauxite particles, 20wt% of tertiary bauxite fine powder, 7wt% of silica micropowder, 2wt% of alumina micropowder, 1wt% of anti-aluminum liquid wetting agent (BaSO 4 0.8wt%, Na 3 AlF 6 0.2wt%), pure calcium aluminate cement 6wt%, plus 0.12% sodium tripolyphosphate, plus 0.03wt% sodium hexametaphosphate. First, the three-grade bauxite fine powder, BaSO 4 0.8wt% and Na 3 AlF 6 0.2wt% barium salt was co-milled and homogenized at 20wt%: 0.8wt%: 0.2wt% for 30 minutes, and then the co-milled homogenized material was poured according to the proportion of three-grade alumina fine powder and barium salt in the castable The other components in the material are mixed evenly with a forced mixer. That is, a high-alumina castable that is not wetted by the aluminum liquid i...

Embodiment 3

[0028] A kind of preparation method of high-alumina castable that is not wetted by aluminum liquid prepares Al 2 o 3 A refractory castable with a content of 56-75%. The composition of the castable is 64wt% of tertiary alumina particles, 21wt% of mullite fine powder, 5wt% of silica micropowder, 2wt% of alumina micropowder, 3wt% of anti-aluminum liquid wetting agent (BaSO 4 2.4wt%, Na 3 AlF 6 0.6wt%), pure calcium aluminate cement 5wt%, plus 0.09% sodium tripolyphosphate, plus 0.05wt% sodium hexametaphosphate. First, the mullite fine powder and barium salt were co-milled and homogenized at 21wt%: 3wt% for 30 minutes, and then the co-milled homogenized material was mixed according to the proportion of mullite fine powder and barium salt in the castable and the castable The other components in the mixture were mixed evenly with a forced mixer. That is, a high-alumina castable that is not wetted by the aluminum liquid is prepared.

[0029] The pouring material of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com