Rewinding roller structure used in toilet paper rewinding machine and rewinding method thereof

A toilet paper roll and rewinding roll technology, which is applied in the field of paper product processing, can solve the problems affecting the bulkiness and softness of toilet paper products, pattern deformation, and poor hand feeling, and achieve good hand feeling effect, good bulkiness and softness High degree of practicality and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

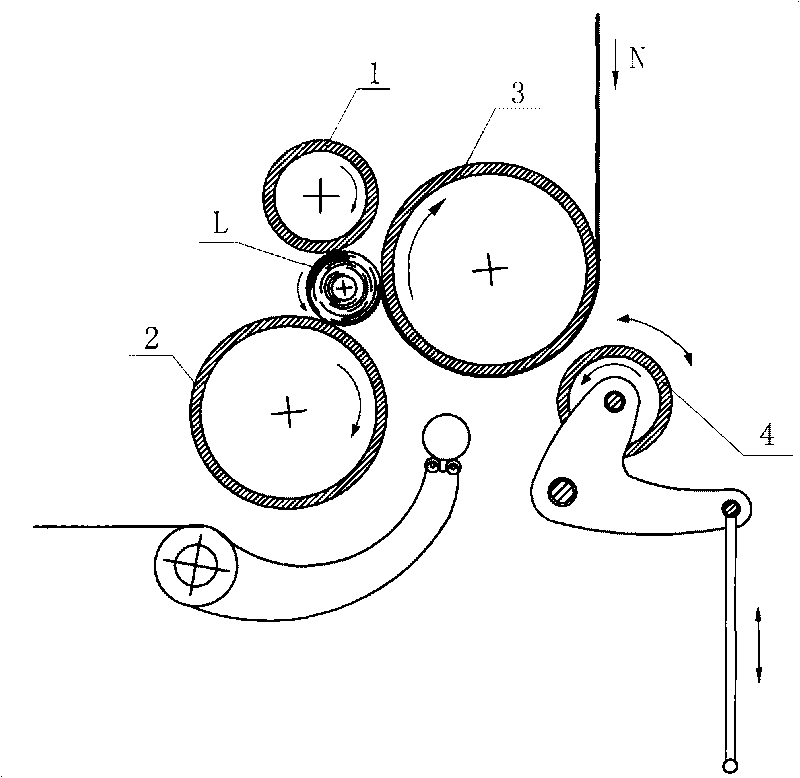

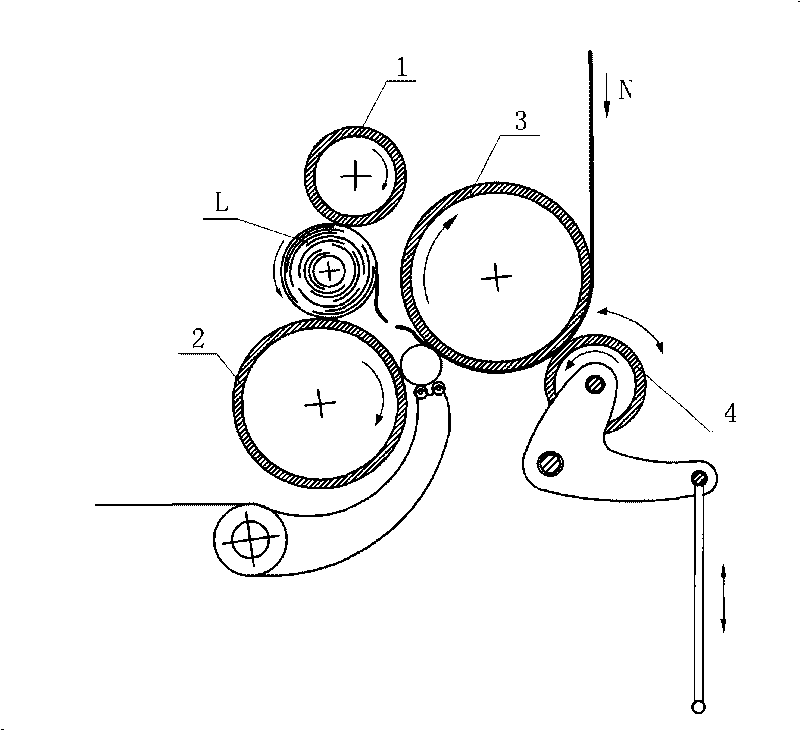

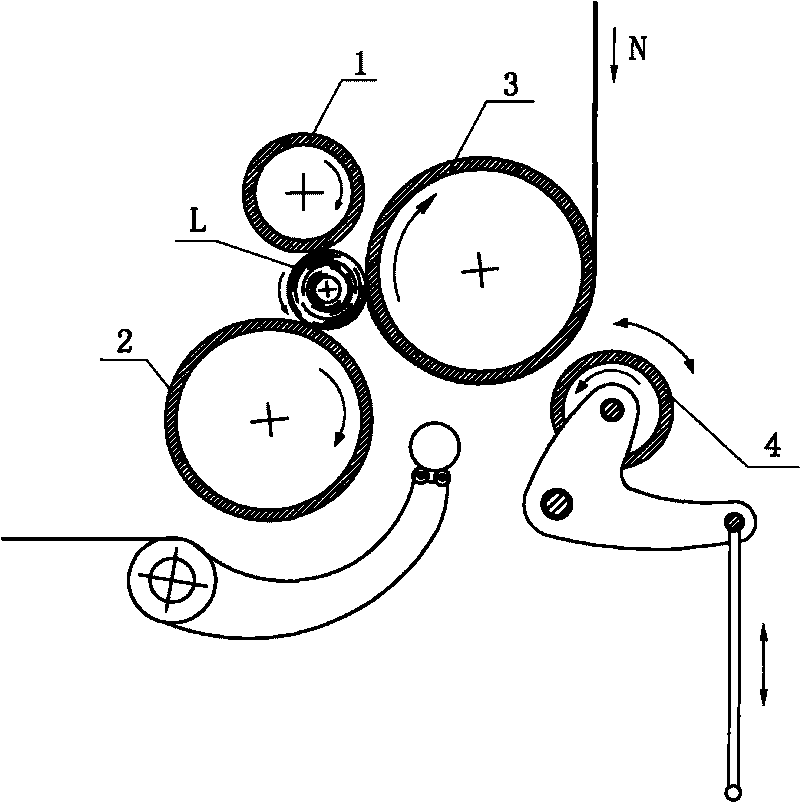

[0016] like Figure 1 to Figure 2 As shown in the figure, a rewinding roller structure for a toilet paper rewinding machine according to the present invention includes an upper rewinding roller 1, a lower rewinding roller 2, a rear rewinding roller 3 and a rear rewinding roller 3 installed in sequence. The roller 3 has a pressing roller 4 with the same linear speed, wherein the pressing roller 4 opens and closes with the rear rewinding roller 3 in a timely manner through the drive of a driving mechanism during the rewinding of the base paper and the speed-up of the upper rewinding roller 1 to break the base paper. ground contact. Wherein, the above-mentioned driving mechanism is an air cylinder or a synchronous cam or a servo motor.

[0017] A rewinding method for a toilet paper rewinding machine according to the present invention comprises the following steps:

[0018] (1) A pressing roller 4 that can be opened and closed with the rear rewinding roller 3 and has the same li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com