Hole plug

A hole plug and leg technology, which is used in gas/liquid distribution and storage, pressure vessels, superstructures, etc., can solve problems such as the loss of freedom of hole plug design, difficulty in ensuring high water resistance, and hindering miniaturization. Simple structure, improved water resistance, and the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

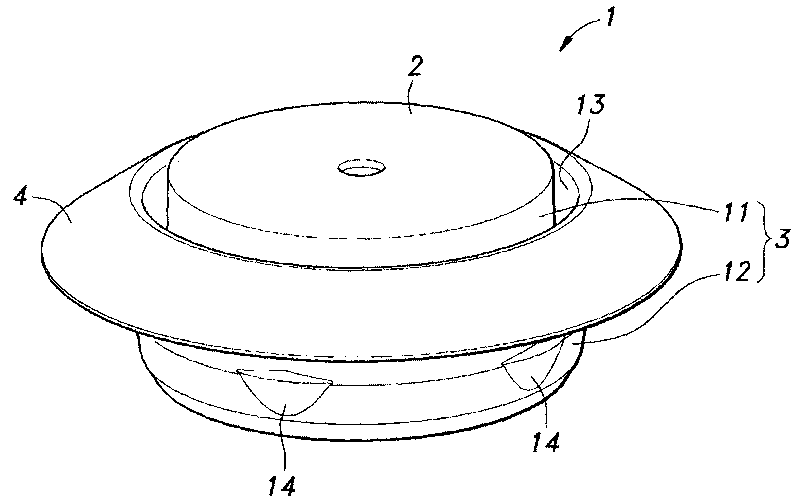

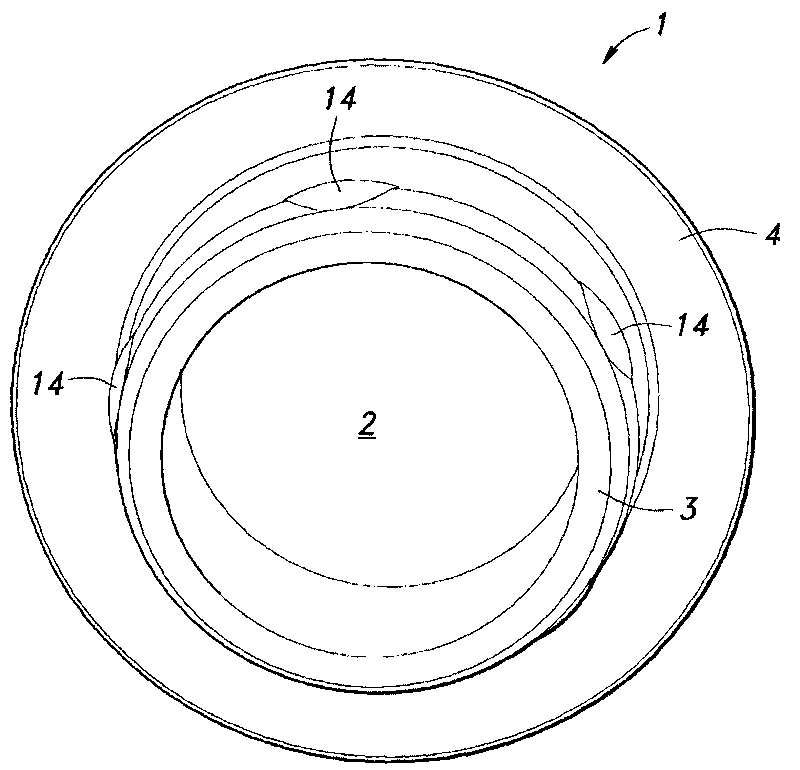

[0026] Embodiments of the present invention will be described below with reference to the drawings. In the following, unless otherwise specified, the terms "up" and "down" indicating directions are in accordance with Figure 4 The orientation of the plug 1 is shown (ie, the head 2 side is the upper side and the leg 3 side is the lower side).

[0027] figure 1 and figure 2 are perspective views of the hole plug of the present invention observed from the upper side and the lower side, respectively, image 3 is the top view of hole plug, Figure 4 is along image 3 Partial sectional view of line IV-IV in, Figure 5 It is a partial enlarged view showing the detailed structure of locking claws and ribs. and, Figure 5 Shows the structure of the plug viewed from the bottom.

[0028] Such as figure 1 and figure 2 As shown, the hole plug 1 is used to close the hole 22 (refer to Image 6 ) includes a head 2 made of a circular flat plate, a leg 3 protruding downward from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com