Fishbone drop irrigation douche runner

An emitter and fishbone-shaped technology, which is applied in the field of fishbone-shaped drip irrigation emitter flow channel, can solve the problems of complex manufacturing and achieve the effects of improved hydraulic performance, reduced sensitivity coefficient, and enhanced anti-clogging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

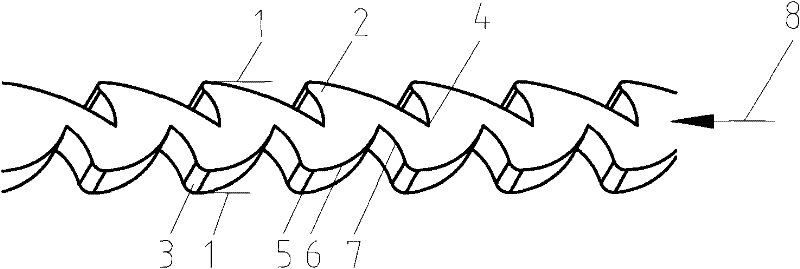

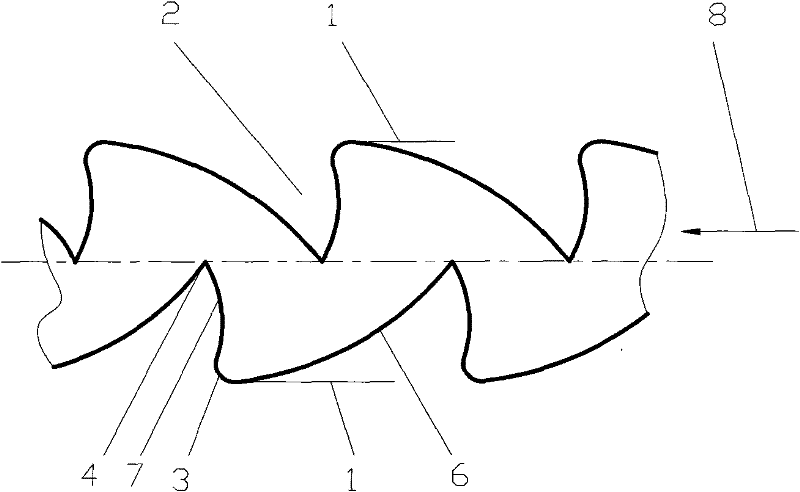

[0028] Such as figure 1 , figure 2 As shown, a fishbone-shaped drip irrigation emitter flow channel is formed by the upper and lower boundaries 1 and the width 5 of the flow channel to form a groove-shaped flow channel. The tooth profile angle 2 of the lower boundary is arranged in a staggered manner; the tooth profile angle 2 is composed of two circular arcs of different sizes, wherein the center of the larger circular arc 6 is different from the center plane of the larger circular arc 6 located in the length direction of the flow channel. side, the center of the smaller arc 7 and the smaller arc 7 are located on the same side of the center plane in the length direction of the flow channel; the dedendum intersection angle of the two tooth profile angles 2 connected to each other is an arc chamfer 3; the tooth profile The tooth tip 4 of angle 2 is located on the center plane in the length direction of the flow channel or extends to the other side of the center plane in the l...

Embodiment 2

[0031] The product in Example 1 is used in the thin-walled (wall thickness can be increased under other pressures) drip irrigation belt in micro-pressure drip irrigation, and the following 5 kinds of implementation methods can be realized to be commercialized.

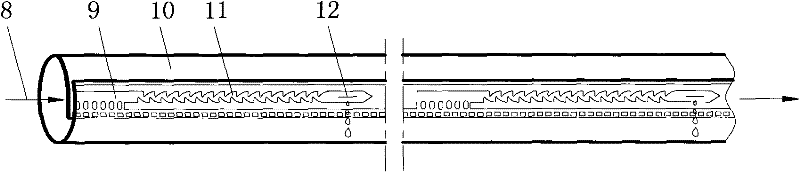

[0032] 1. Form a thin-walled laminated drip irrigation belt, such as image 3 as shown,

[0033] The flow channel 11 of the fishbone drip irrigation emitter of the present invention is formed into a thin-walled drip irrigation belt with the above-mentioned flow channel by staggering the inside and outside of the two side walls of the thin-walled plastic film and using plastic mold heat sealing or other bonding methods. The water end is bonded into a small granular filter water inlet 9, which is convenient for filtering larger impurities in the water. There is a larger water outlet pool at the water outlet end of the flow channel, and a small slit water outlet 12 is opened on the water outlet pool to facilitate water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com