Front-located shaft type tubular pump water inlet flow passage with excellent hydraulic performance and application method thereof

A technology of water inlet channel and hydraulic performance, which is applied in the direction of hydroelectric power generation, water supply equipment, hydropower station, etc., can solve the problems of complex three-dimensional shape of water inlet channel, long design cycle, and difficult design, and achieve streamlined hierarchy, Excellent hydraulic performance and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) The inlet channel of the front shaft type tubular pump with excellent hydraulic performance of the present invention is as follows:

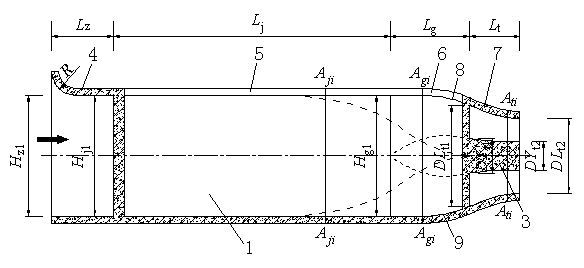

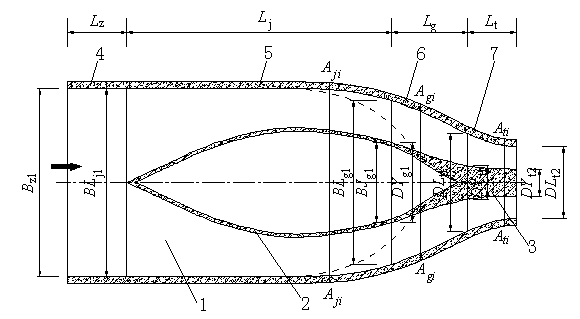

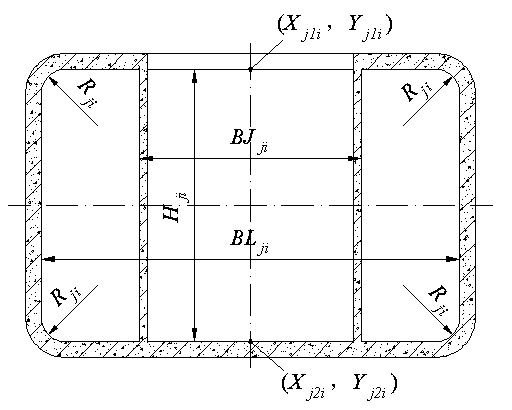

[0055] The inlet flow channel of the pre-shaft type tubular pump provided by the present invention is provided with a straight line inlet section 4, a shaft flow section 5, an intersecting confluence section 6 and a circular table rectification section 7 along the water flow direction, and the data of each section adopts relative values Indicates; the length L of the straight inlet section 4 z 0.8D, height H z1 1.576D, width B z1 2.545D, inlet roof arc radius R=0.3077D-0.0154m; the length L of the shaft flow section 5 j 3.586D, inlet width BL j1 2.545D, height H j1 is 1.576D, the coordinates (X j1i , Y j1i ), the coordinates of the bottom line 9 (X j2i , Y j2i ), runner height H ji , width BL ji , transition circle radius R ji and shaft width BJ ji and other data are shown in Table 1, and the positions of each section are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com