Multi-working-condition multi-target hydraulic optimization method for impeller of centrifugal pump with ultralow specific speed

A centrifugal pump impeller and hydraulic optimization technology, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems that have not yet been reported publicly about the multi-condition and multi-objective hydraulic optimization method for ultra-low specific speed centrifugal pump impellers , to achieve the effect of improving computational efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

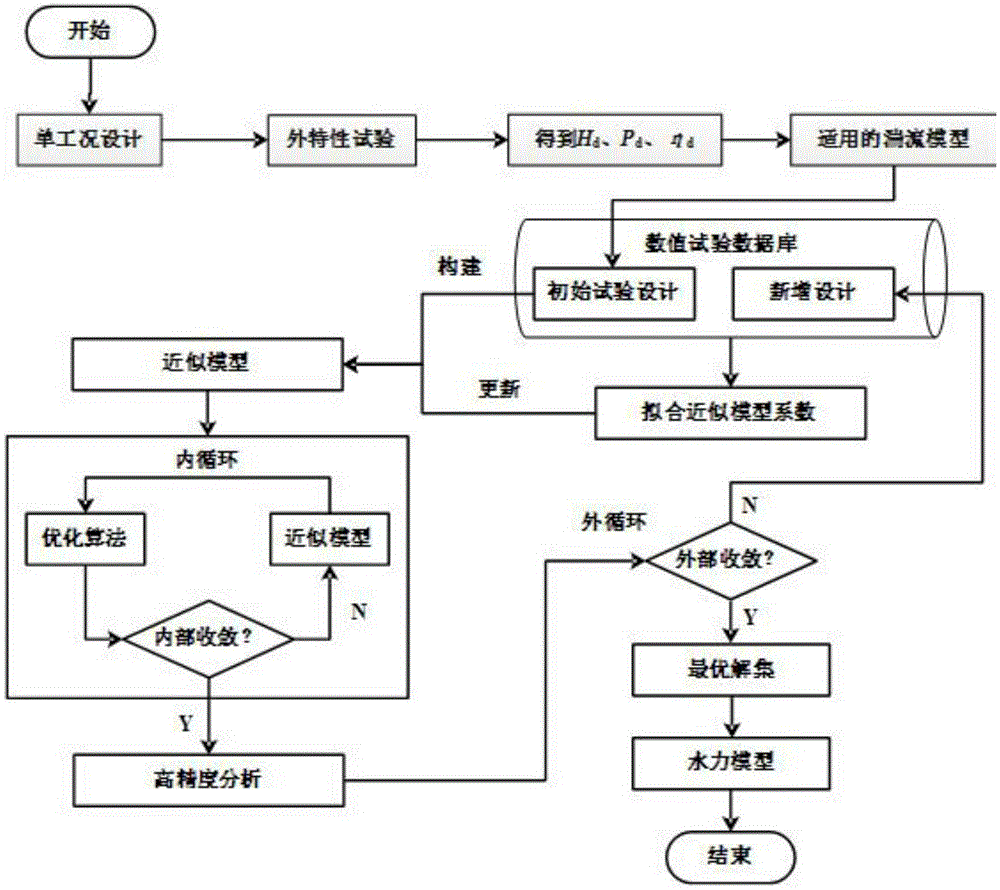

Method used

Image

Examples

Embodiment

[0028] An ultra-low specific speed centrifugal pump with a specific speed of 24.1, and its design flow rate is Q d =0.4m 3 / h, H d =40m, n=10000r / min.

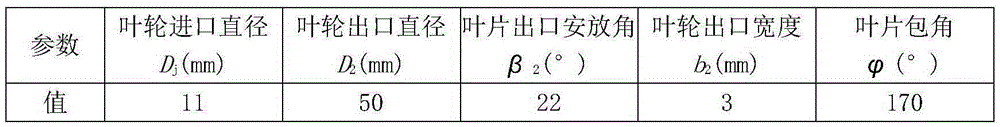

[0029] (1) The ultra-low specific speed centrifugal pump is designed using the single working condition design method, and the key geometric parameters of the impeller are shown in Table 1.

[0030] Table 1 Values of key geometric parameters of the impeller in single-point design

[0031]

[0032] Process ultra-low specific speed centrifugal pumps, build a test bench for the external characteristics of ultra-low specific speed centrifugal pumps, and measure the head, power and efficiency of ultra-low specific speed centrifugal pumps under various working conditions.

[0033] 0.8Q d , Q d , 1.2Q d The test results of the external characteristics of the ultra-low specific speed centrifugal pump under three working conditions are: H 1 =42.1m, P 1 =103.7W, η 1 = 28.4%; H 2 =40.6m, P 2 =108.5W, η 2 = 32.6%; H 3 =3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com