Apparatus and method for calibrating a scanning head

A technology of head and angular orientation, applied in the direction of measuring devices, instruments, etc., to achieve the effect of improving calibration accuracy and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

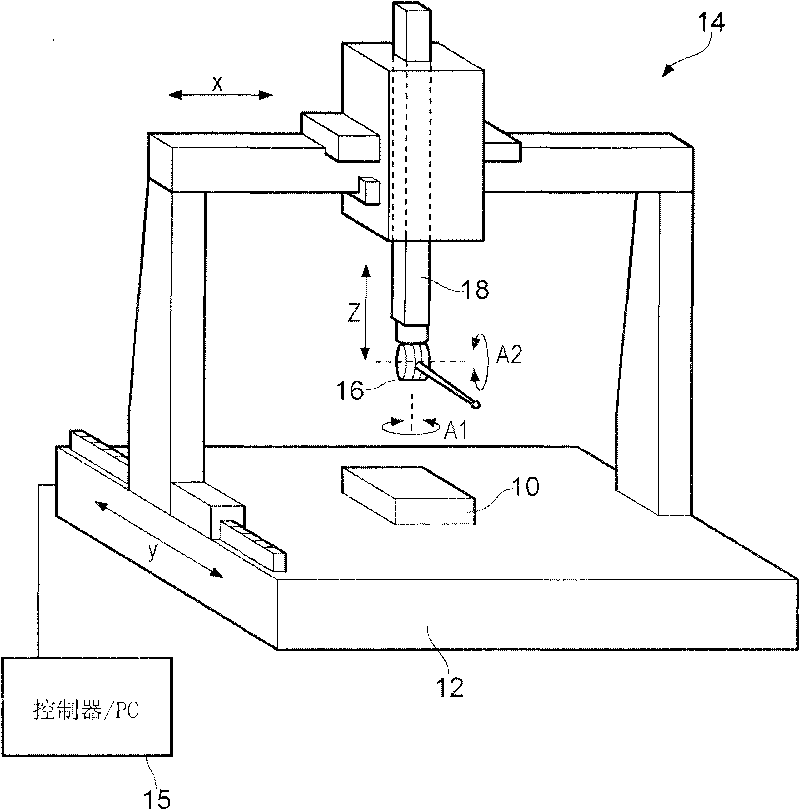

[0050] figure 1 A motor-driven scanning head is shown mounted on a coordinate locator, such as a coordinate measuring machine (CMM). The workpiece 10 to be measured is installed on the worktable 12 of the CMM 14 , and the motor-driven scanning head 16 is installed on the spindle 18 of the CMM 14 . The mandrel can be driven in the X, Y, Z directions relative to the table by means of a motor in a known manner. Other types of coordinate positioners can be used, such as machine tools, manual CMMs, or robotic arms.

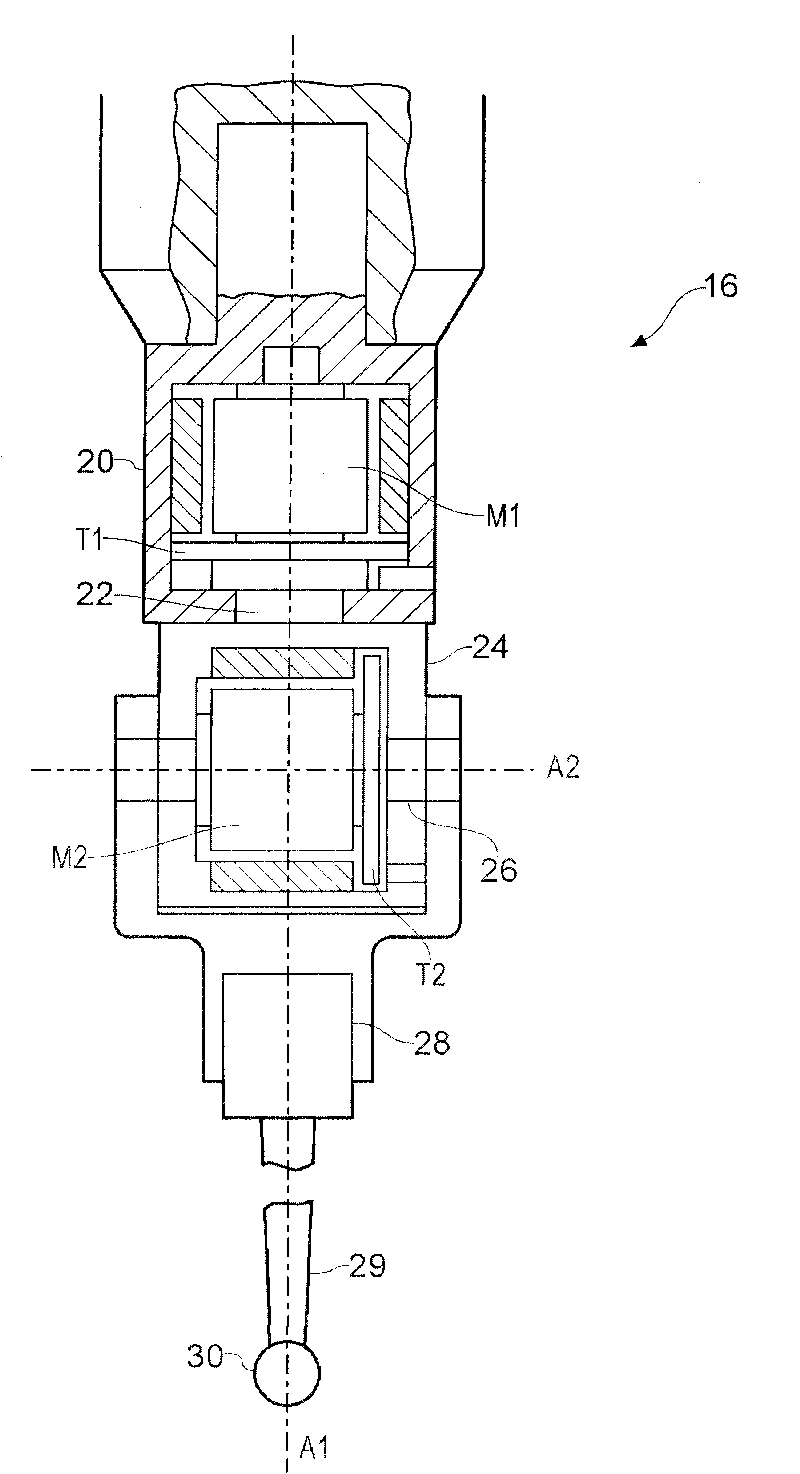

[0051] like figure 2 As shown, the motor-driven scanning head 16 comprises a stationary part formed by a base body or housing 20 which supports a movable part in the form of a shaft 22 which can be moved relative to the housing 20 about the axis A1 by means of the motor M1. turn. The shaft 22 is fastened to a further housing 24 which in turn supports a shaft 26 which is rotatable relative to the housing 24 by means of a motor M2 about an axis A2 which is perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com