Method for simulating drilling tool lifting for drilling simulator

A simulation method and simulator technology, applied in the direction of instruments, educational tools, teaching models, etc., can solve the problems of training content limitation, training system, training effect and the number of trainees, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0175] The technical solutions of the present invention are further described below by way of examples, and the present invention is not limited to the examples.

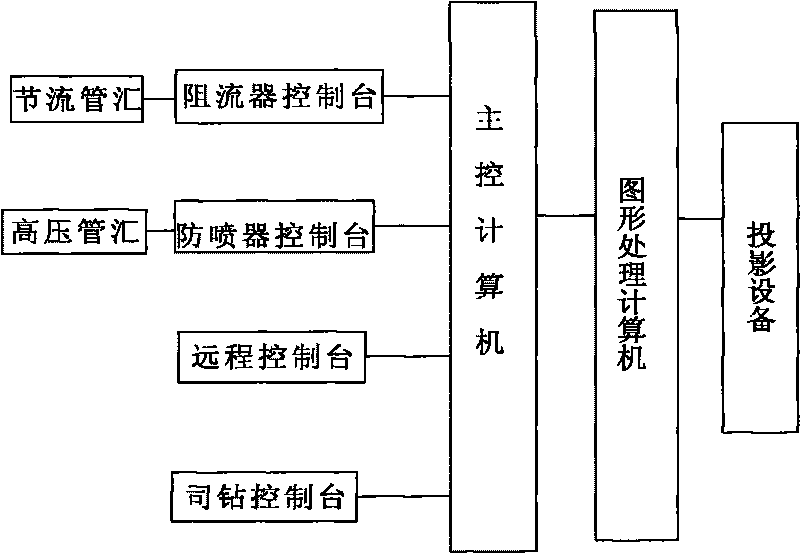

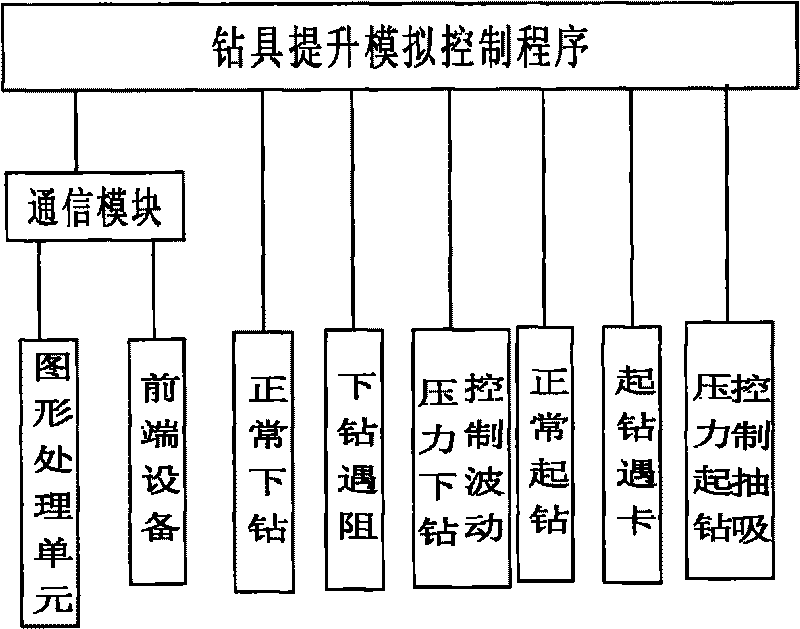

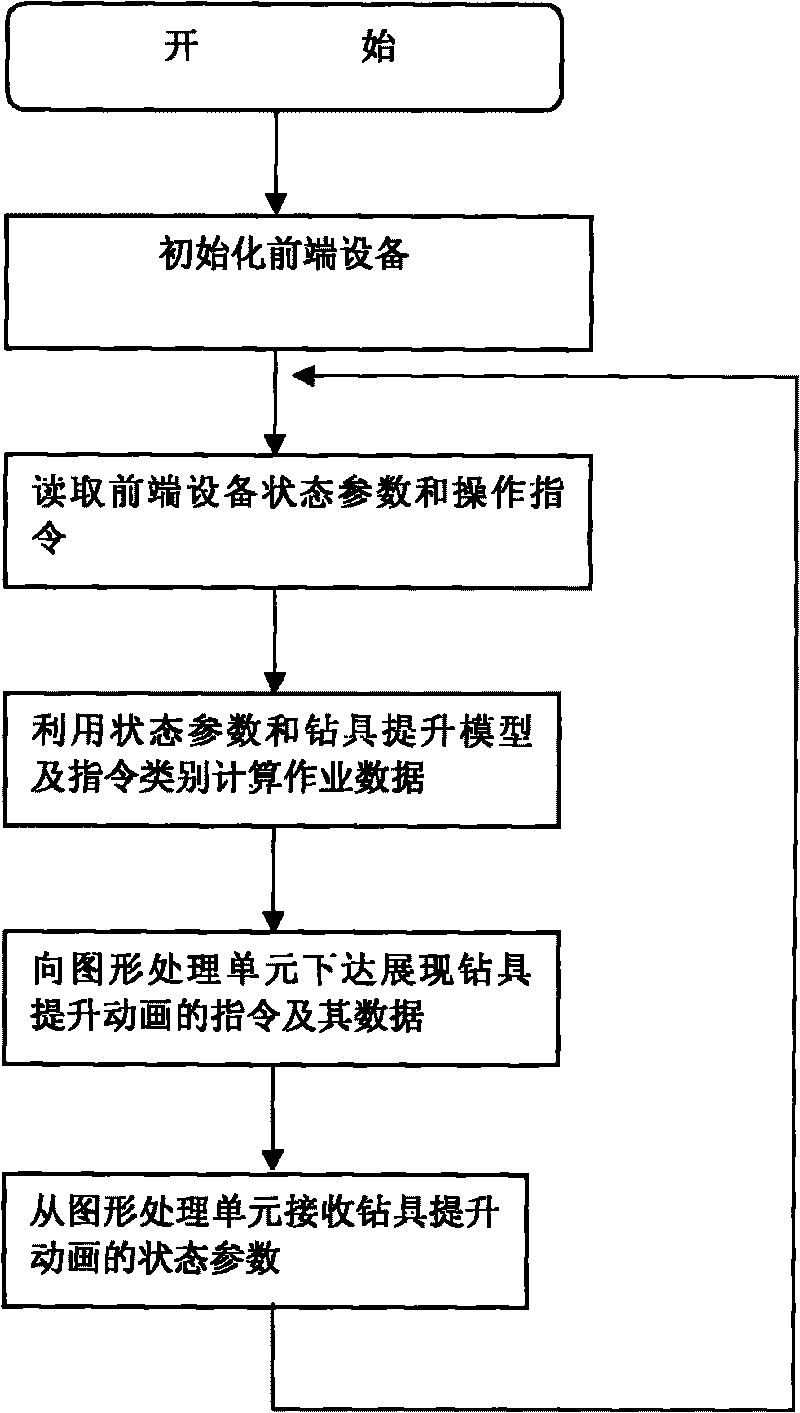

[0176] In order to implement the technical scheme described in the present invention, a drilling simulation system has been constructed, such as figure 1 , which includes the main control computer, graphics processing computer, front-end equipment and projection equipment, the main control computer and the graphics processing computer are interconnected through TCP / IP, the front-end equipment and the main control computer are interconnected through the Siemens PPI protocol, the graphics processing computer is connected to the projection equipment, and the main The drilling tool lifting simulation control program runs on the control computer, the graphics processing computer runs the graphics processing unit, and the front-end equipment includes choke manifold, high-pressure manifold, blowout preventer console, choke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com