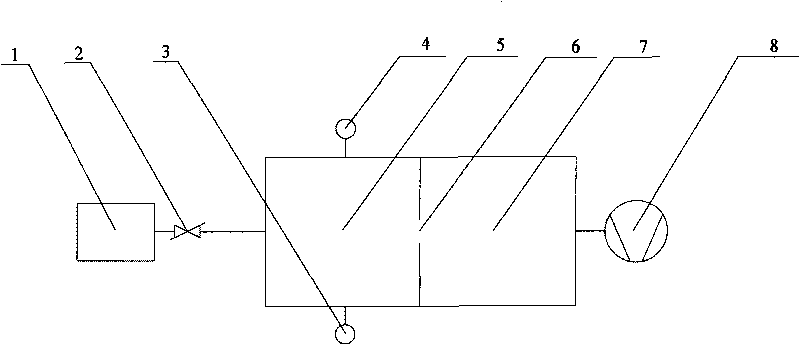

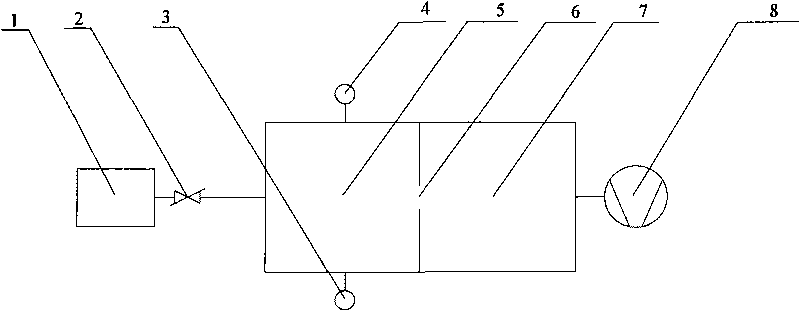

Device and method for measuring pumping speed and outgasing rate of ionization gauge

A measurement device and measurement method technology, applied in the field of measurement, can solve the problem of inability to accurately calculate the absolute gas output rate of an ionization gauge, that is, the gas output rate, etc., and achieve small measurement uncertainty, calculation of pumping speed and gas output rate, pumping speed and gas output. Rate-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] 1) Start the air extraction unit 8, and exhaust the upper vacuum chamber 5 and the lower vacuum chamber 7;

[0047] 2) Start the flowmeter 1 pumping unit, and pump all the vacuum pipes of the flowmeter;

[0048] 3) Carry out overall baking and degassing of the measuring device, the baking temperature of the flowmeter 1, the measured ionization gauge 3, and the reference gauge 4 is 150°C, and the baking temperature of the upper vacuum chamber 5 and the lower vacuum chamber 7 is 300°C ℃, after the baking temperature gradually rises to the highest point at a uniform rate, keep it for 72 hours, and then gradually lowers to room temperature at a uniform rate, and the uniform rate of rising and falling of the baking temperature is 30°C / h;

[0049] 4) Continue pumping for 24-48 hours until the upper vacuum chamber 5 reaches 10 -8Ultimate vacuum in the order of Pa;

[0050] 5) Fill the flowmeter 1 with a pressure of 3.6×10 -3 Pa gas, adjust the variable conductance valve 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com