Double-deck continuous steel girder bridge for rigid suspended cable stiffening

A steel truss bridge and rigid technology, which is applied in the field of double-layer continuous steel truss bridges, can solve the problems of small force on stiffened chords and hangers, increase in bridge deck height, and increase in length of approach bridges. The effect of reducing the height of the truss and reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

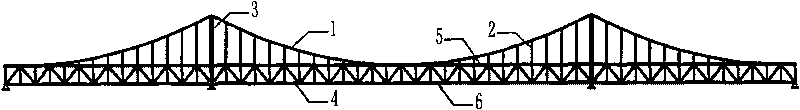

[0021] refer to figure 1 , the rigid suspender 2 of the present invention, the lower end of the fulcrum column 3 is connected with the upper chord node of the main truss 4, the fulcrum column 3, the upper end of the rigid suspender 2 is connected with the rigid suspension cable stiffening chord 1 node, and the upper layer 5 and the lower layer 6 of the main truss 4 are both Driveable.

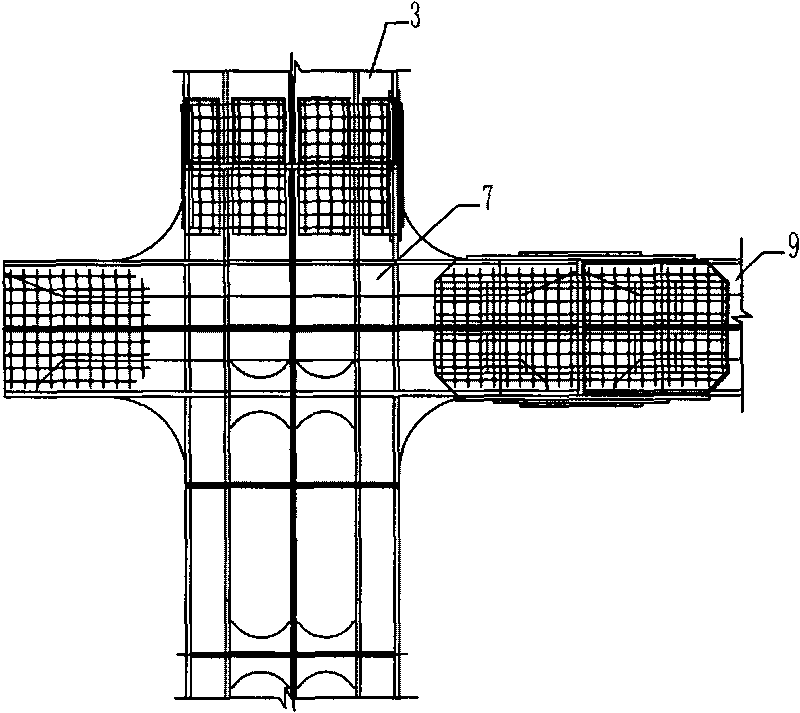

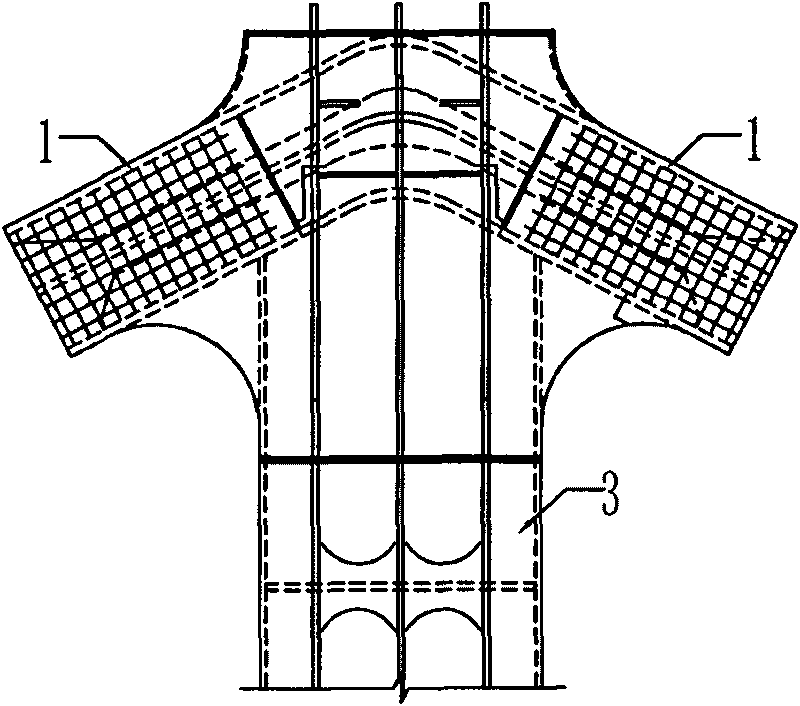

[0022] The main chord part of the present invention is basically the same as the steel truss bridge without stiffening chord. The upper chord node 7 at the fulcrum column is adopted as figure 2 , 3 As shown in the 'cross'-shaped structure, the chords 9 of the main truss are horizontally connected to both ends, the fulcrum columns 3 are connected vertically, and the vertical bars 10 of the main truss are connected below (see Figure 4 ). The top of the fulcrum column is connected with the rigid suspension cable stiffener 1 of the middle span and side span. Rigid suspension cable stiffening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com