Electrical connector locking mechanism

A technology of electrical connectors and locking mechanisms, which is applied in the direction of connection, parts and circuits of connection devices, and can solve the problems of unreliable sealing contact between plugs and sockets, difficult plug assembly and disassembly, and low vibration resistance of electrical connectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

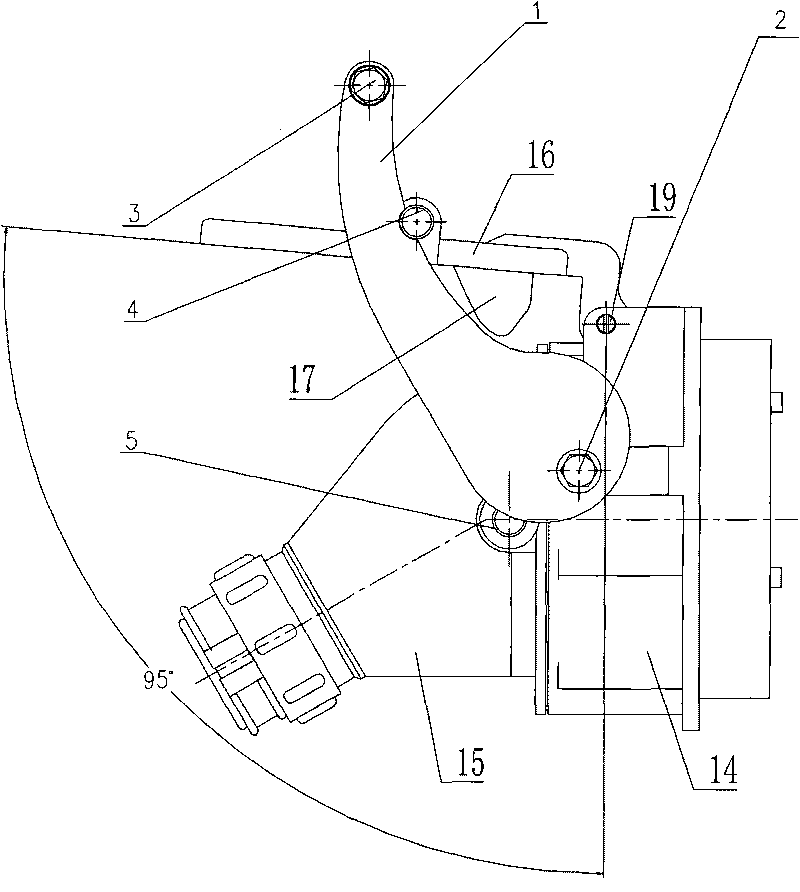

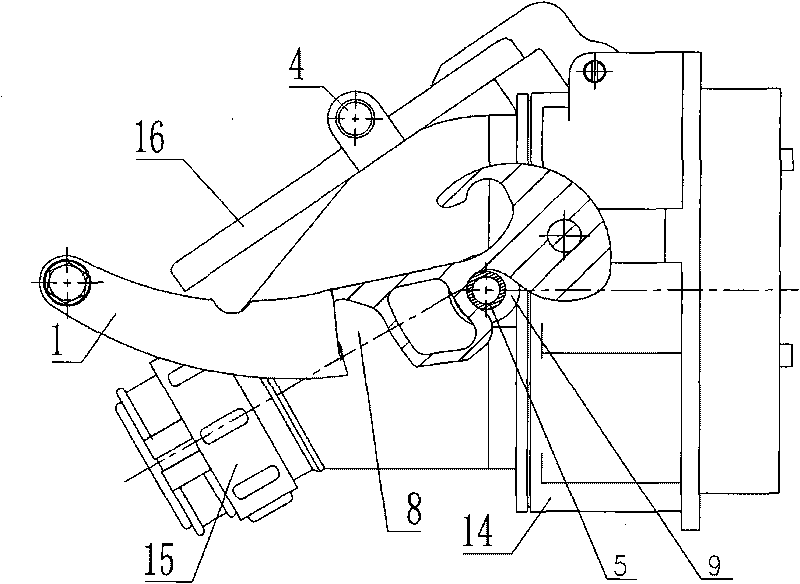

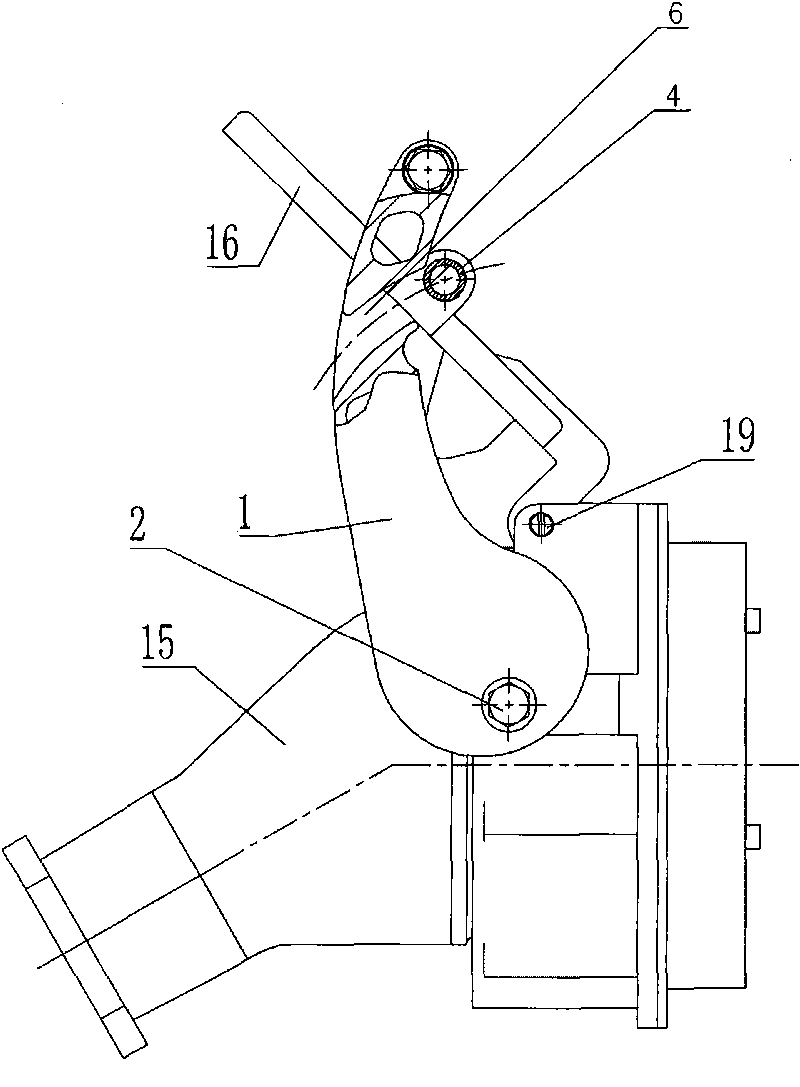

[0021] see Figure 1-7 As shown, the electrical connector includes a socket 14, a plug 15 that is pluggably connected with the socket, and a protective cover 16; the lower surface of the protective cover has a protrusion 17, and when the plug is inserted into the socket, the protrusion can press the corresponding recess 13 on the plug . The protective cover 16 is turned over and connected on the socket by the protective cover shaft 19, and the torsion spring 12 that makes the protective cover turn downwards is sleeved on the protective cover shaft 19 in normal state.

[0022] see Figure 1-6 As shown, the rocker arm locking mechanism of the electrical connector includes two rocker arms 1 , two protective cover locking rollers 4 , two plug locking rollers 5 and a handle 3 . A protective cover locking roller 4 is respectively connected to both sides of the protective cover 16 . Two rocking arms 1 are on both sides of the protective cover, and are parallel to each other, and t...

Embodiment 2

[0029] Example 2 see Figure 5 , 7 , The electrical connector in 8, its plug 15 adopts existing plug (that is, the plug 15 removes the plug locking roller 5 in the embodiment 1). Other structures are with embodiment 1. The locking process when the plug is inserted into the socket:

[0030] Push the handle 3 to make the protective cover locking roller 4 on the protective cover fall into the protective cover positioning groove 7, insert the existing plug into the socket; continue to push the handle 3 to make the protective cover locking roller 4 on the protective cover Slip out from the shifting groove 6 of the protective cover, that is Figure 5 status shown. The protective cover is turned over freely again, and the protrusion 17 falls into the recess 13 on the plug, that is, Figure 7 As shown; push the handle 3 in the opposite direction, so that the first protective cover locking chute 8 on the rocker arm 1 is located above the position of the protective cover locking ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com