Lead stranding die mold device with low wind noise

A compression molding device, wind noise technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of high wind noise and noise pollution of wires, and achieve improved twisting capacity, flexible rotation, and good rotational symmetry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

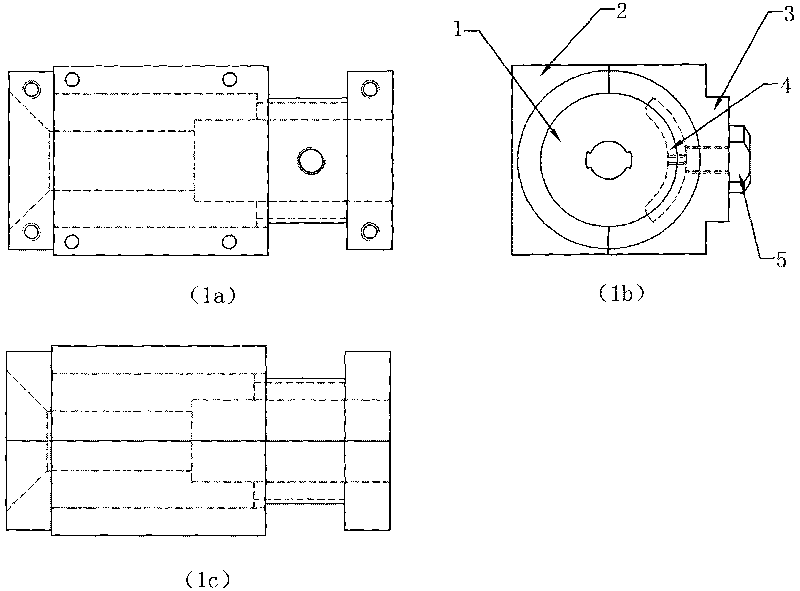

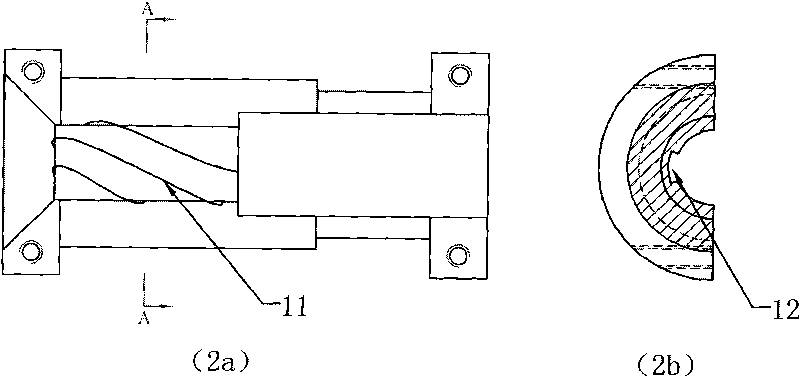

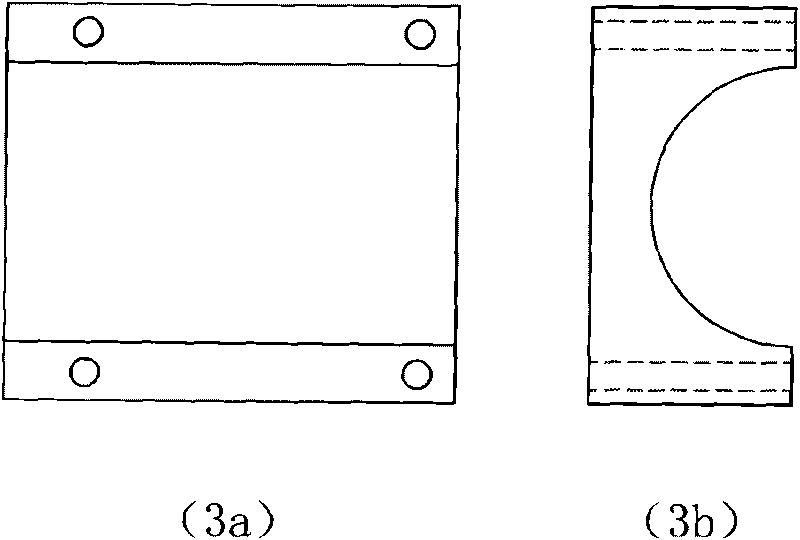

[0021] Such as Figure 1-6 As shown, it is a schematic diagram of the overall assembly of a low wind noise wire twisting die device of the present invention and a schematic view of the structure of each component. The device includes two rotatable inner dies 1, a first fixed outer die 2, a second Two fixed outer dies 3, adjusting torque friction plates 4 and adjusting torque bolts 5, the inner rings of the first fixed outer die 2 and the second fixed outer die 3 are semi-circular, and the two form a Complete ring, the outside of the second fixed outer die 3 has a protrusion 31 for installing the adjusting torque bolt 5, and two semi-circular rotatable inner dies 1 also form a complete circle The ring is arranged in the ring formed by the first fixed outer die 2 and the second fixed outer die 3, and the inner die 1 can be rotated so that the first fixed outer die 2 and the second fixed outer die 3 The center of the formed ring is a shaft that can rotate freely. After the two r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com