Coolant system of heat testing machine of automobile engine and coolant supplying method

A technology of coolant and engine, applied in the field of coolant system, can solve the problems of aging of coolant pipeline and leakage of coolant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

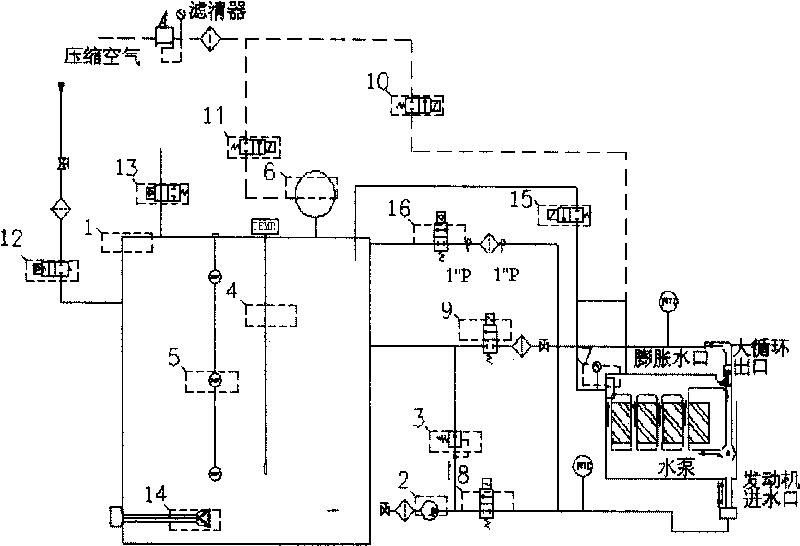

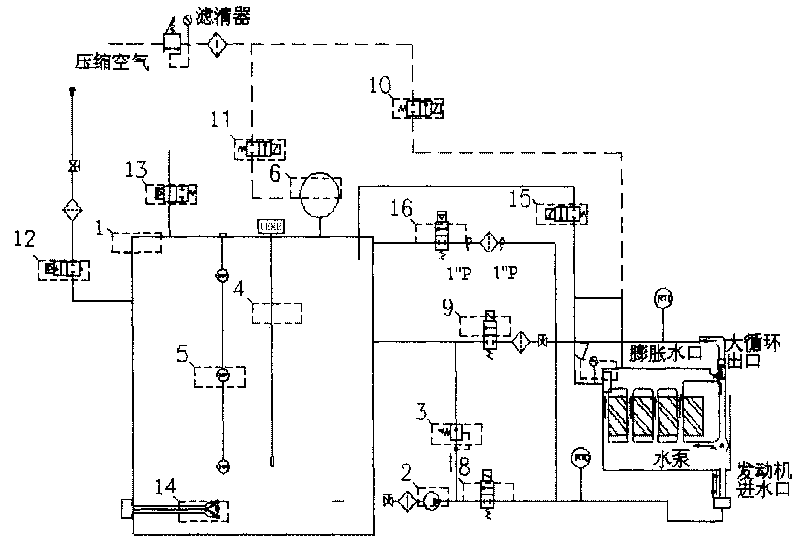

[0021] Attached below figure 1 The present invention is described in further detail:

[0022] First, the role of the main components:

[0023] Heater 14: Heating the temperature of the cooling liquid to reduce the production cycle.

[0024] Temperature sensor 4: Control whether the heater works according to the value measured by the sensor, so that the temperature of the coolant is controlled between 70 and 80 degrees.

[0025] Water pump 2: Automatically supply coolant to the engine.

[0026] Pressure regulating valve 3: reduce the output pressure of the water pump, otherwise it will affect the normal operation of the engine water pump.

[0027] Liquid level gauge 5: Measure the liquid level of the water tank. If the liquid level is too low, the system will control the replenishment valve to open to supplement the coolant.

[0028] Vacuum generator 6: generate vacuum and suck back the coolant;

[0029] Supplementary valve 12: After the hot test of each engine, a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com