Method for monitoring pressure pipeline leakage acoustic emission in nuclear power plant and monitoring system thereof

A pressure pipeline and monitoring system technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of lack of effective estimation of leakage rate, quantitative analysis of leakage, identification and location of pressure pipeline leakage, etc. Achieve the effects of improving real-time performance and sensitivity, improving the ability to resist false alarms, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

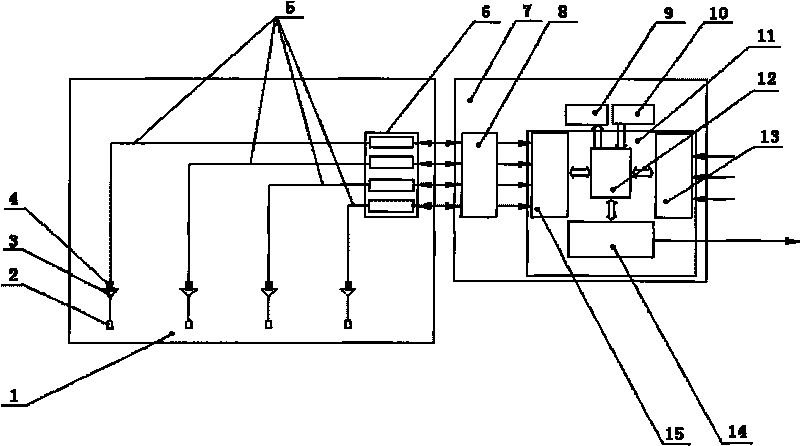

[0106] Using the method and system of the present invention, using the power equipment comprehensive test device as a test platform, respectively connect the processed microporous test piece and the leakage test section of the pressure pipeline through the crack to the test interface of the power equipment comprehensive test device, and the pressure on the nuclear power plant Pipelines are subjected to thermoacoustic effect test of insulation layer, micropore leakage test and acoustic emission test of pipeline through crack leakage:

[0107] Four 0Cr18Ni10Ti high-pressure pipes with an outer diameter of Φ152mm, a wall thickness of 12mm, and a length of 7700mm (consisting of a 500mm-long crack test piece and a 3600mm long pipe section before and after welding) were used as test pieces, and processed by EDM. Etch an axial V-shaped groove on the inner surface, use the pressure pipeline crack opening area calculation model and the crack leakage calculation model to calculate the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com