Glass plastic product with composite material resin circular fiber power

A technology of glass-plastic products and ring fiber powder, which is applied in the field of building materials and its processing, can solve the problems that resin ring fiber powder cannot be recycled, and achieve the effects of promoting the development of circular economy, realizing recycling, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

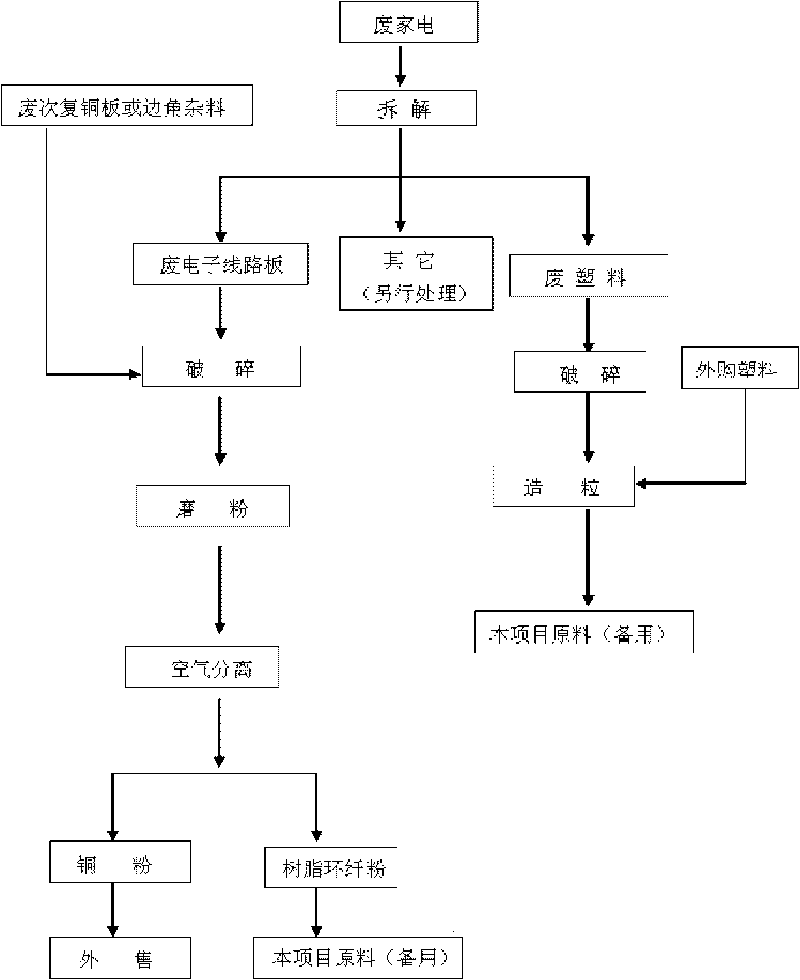

Method used

Image

Examples

Embodiment 1

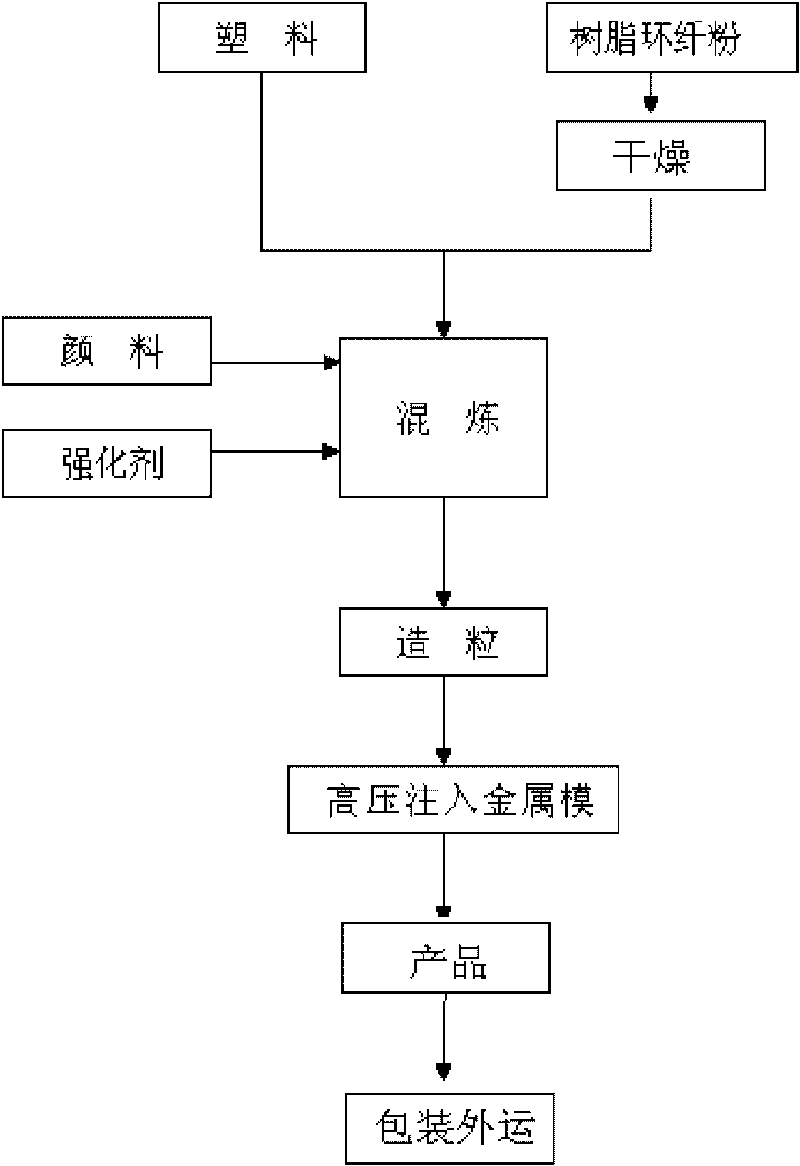

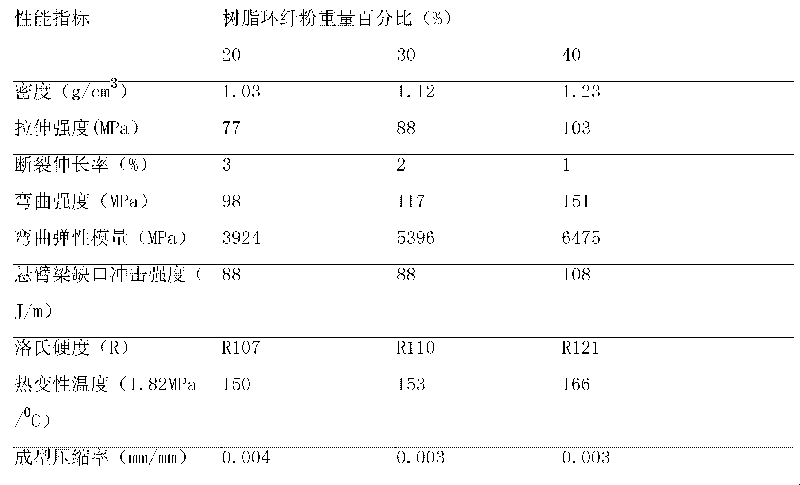

[0022] A glass-plastic product with composite material resin ring fiber powder, wherein the plastic accounts for 50% by weight of the glass-plastic product with composite material resin ring fiber powder, the reinforcing agent is 15%, and the rest is resin ring fiber powder , accounting for 35% by weight of glass-plastic products with composite resin ring fiber powder. Among them, the function of the reinforcing agent is mainly to change and enhance the affinity between the glass fiber powder and the plastic.

[0023] The production method of making glass-plastic products from the composite material resin ring fiber powder involved in the present embodiment 1 adopts the following steps:

[0024] First, a 400×800 coarse crusher is used to crush waste electronic circuit boards without components to obtain coarse materials, and the output particles are less than 40 mesh.

[0025] Then the fine material with a particle size of 40 mesh is finely crushed again, and the output parti...

Embodiment 2

[0029] A glass-plastic product with composite material resin ring fiber powder, wherein the plastic accounts for 35% by weight of the glass-plastic product with composite material resin ring fiber powder, the other 15% is a strengthening agent, and the rest is resin ring fiber Powder, which accounts for 50% by weight of the glass-plastic product with composite material resin ring fiber powder.

[0030] The process steps for manufacturing the glass-plastic product with composite resin ring fiber powder described in Example 2 are as in Example 1.

Embodiment 3

[0032] A glass-plastic product with composite material resin ring fiber powder, wherein the plastic accounts for 45% by weight of the glass-plastic product with composite material resin ring fiber powder, and the other 15% is a reinforcing agent, and the rest is resin ring fiber Powder, which accounts for 40% by weight of the glass-plastic product with composite material resin ring fiber powder.

[0033] The process steps for manufacturing the glass-plastic product with composite resin ring fiber powder described in Example 3 are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com