Automatic hoister

An automatic lifting and driving sprocket technology, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of automatic production, high labor intensity, and low production efficiency of large-scale production lines that cannot meet the requirements of large-scale products, and meet the requirements of large-scale production. The effect of large-scale production of products and automatic production of production lines, reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

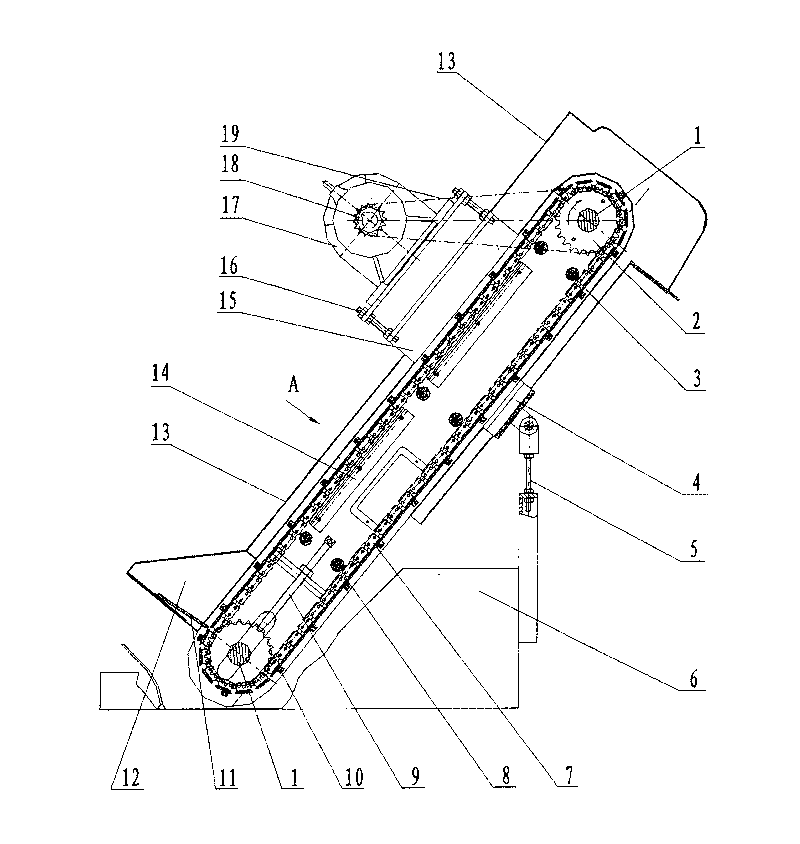

[0011] The preferred embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

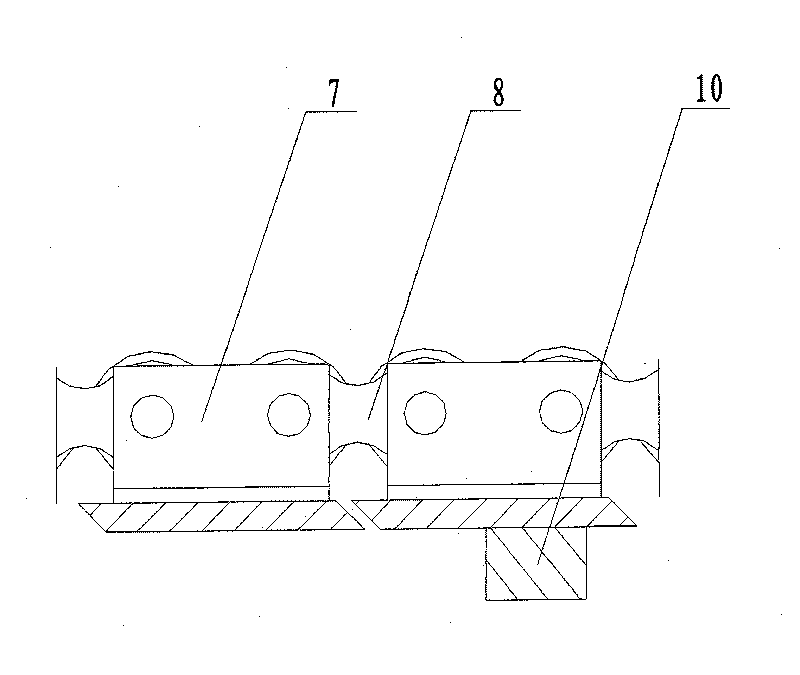

[0012] An automatic hoist, which includes two rotating shafts 1, a large sprocket 2, six structural pillars 3, a connecting block 4, an adjusting screw 5, an oil receiving groove 6, a chain plate 7, two single-ear roller chains 8, Adjusting ejector rod 9, pushing plate 10, material retaining plate 11, hopper 12, casing 13, bearing block 14, fixing seat 15, bolt 16, reduction motor 17, small sprocket 18, roller chain 19, four drives Sprocket 20.

[0013] Referring to the accompanying drawings, 6 structural struts 3 connected by steel members form the framework of the hoist, the geared motor 17 is fixed on the fixed seat 15 by bolts 16, the small sprocket 18 is mounted on the output shaft of the geared motor 17, and the large sprocket 2 is installed on the rotating shaft 1, and the roller chain 19 connects the large sprocket 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com