Connecting device for rear shock absorber of automobile

A technology of connecting device and shock absorber, applied in vehicle parts, transportation and packaging, elastic suspension, etc., can solve the problems of reduced axial preload, inconvenient assembly, elastic hysteresis, etc. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

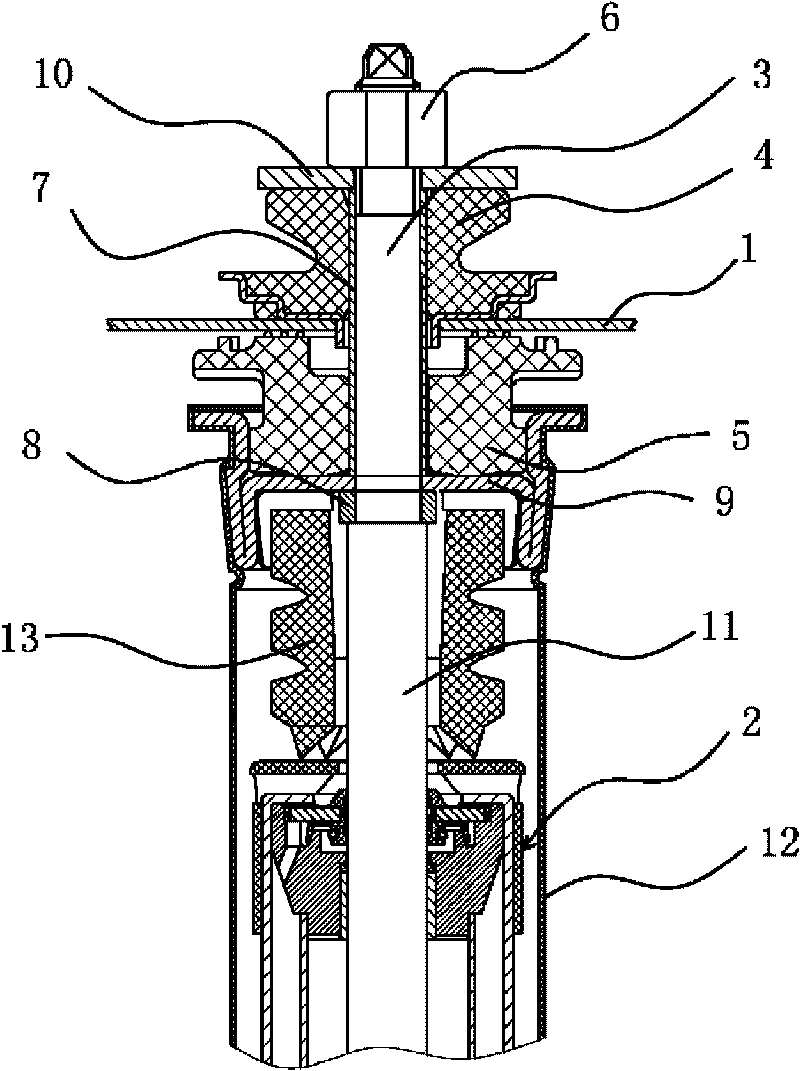

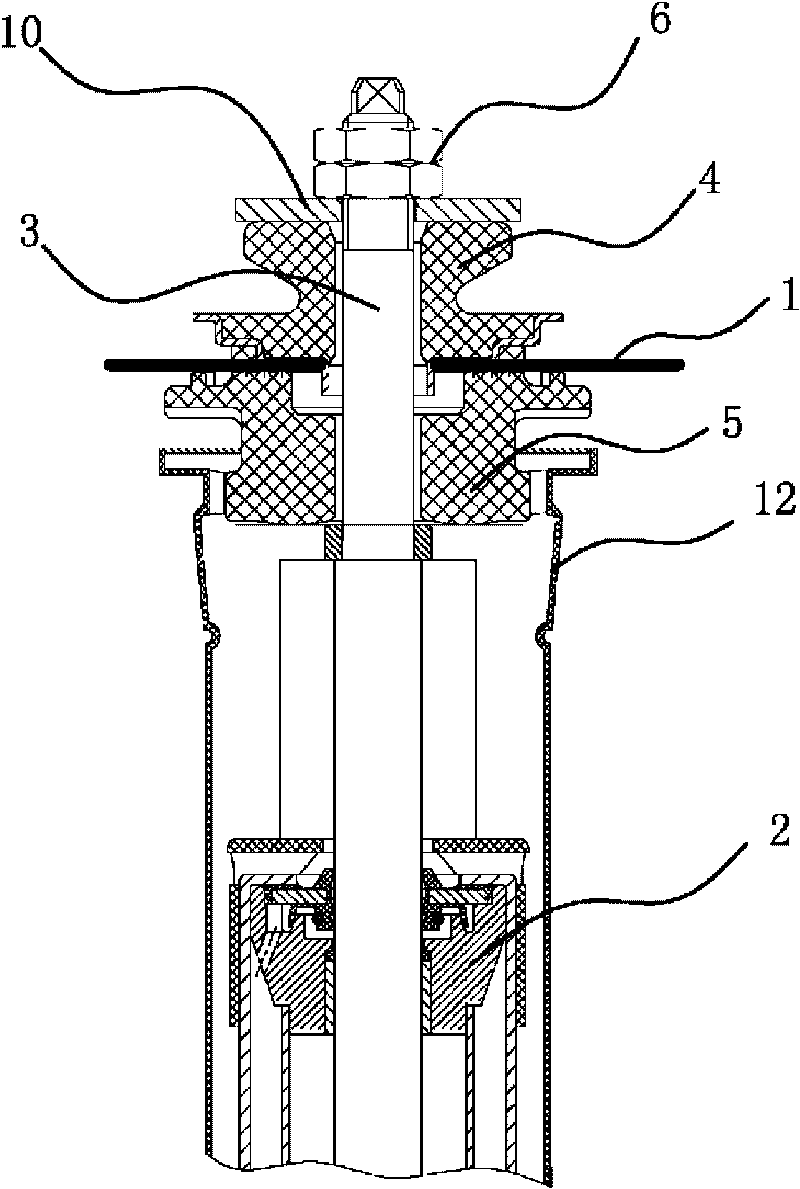

[0020] like figure 1 As shown, the rear shock absorber 2 of the automobile includes a piston rod 11 and a casing 12, and is fixed on the body of the automobile through a connecting device, which includes a bolt 3, a nut 6, an upper support 4 and a lower support 5 and the like.

[0021] Specifically, the connecting device of the rear shock absorber of the automobile is arranged at the connection between the rear shock absorber 2 and the body, including one end being fixedly connected with the housing 12 of the rear shock absorber 2 and the other end passing through the body wall 1 and extending To the bolt 3 on the upper part of the body wall 1, the part of the bolt 3 located at the upper part of the body wall 1 is sleeved with an upper support 4, an upper pressure plate 10 and a nut 6 in sequence, and the upper pressure plate 10 increases the force-bearing area of the reaction force of the nut 6. The large rear is transmitted to the upper support 4, and the upper support 4 ...

Embodiment 2

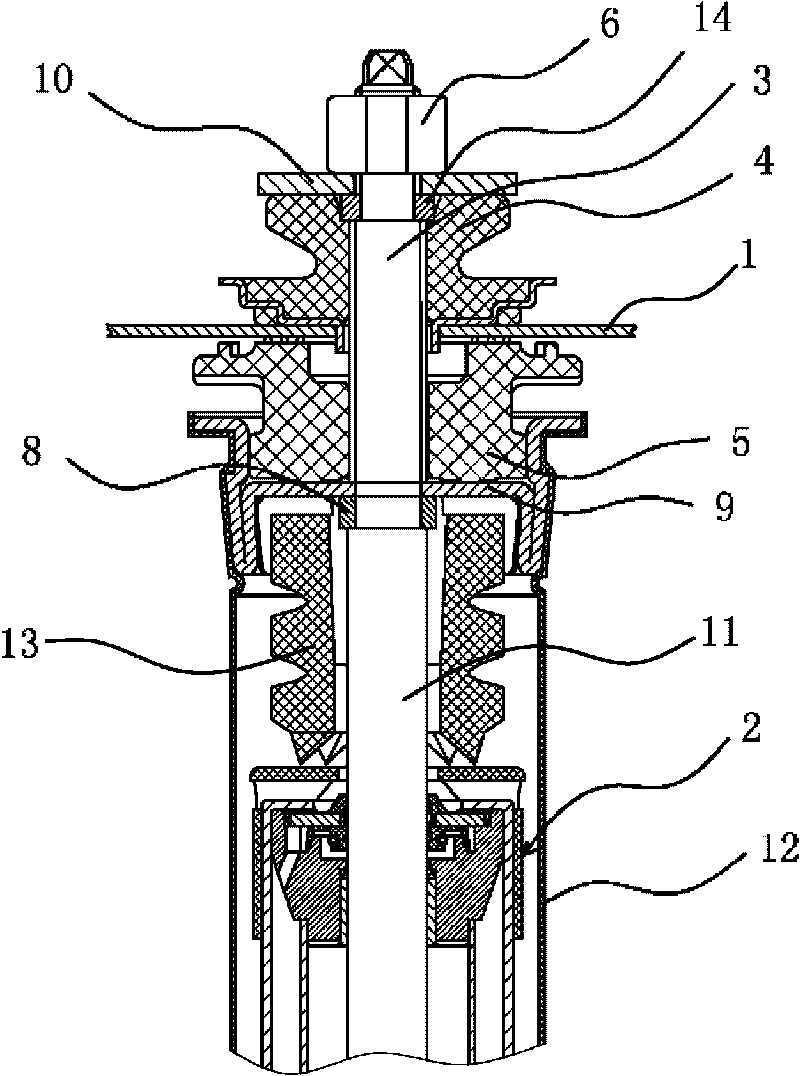

[0025] This embodiment is roughly the same as the first embodiment, the difference is that, as figure 2 As shown, the positioning structure may also include a boss 14 fixed between the side surface of the bolt 3 and the upper support 4 , and the boss 14 is buckled at the lower end of the upper pressing plate 10 . After the nut 6 fixes the upper pressing plate 10 and the boss 14, the upper pressing plate 10, the nut 6 and the boss 14 form a rigid whole. The positioning structure is simple in design, practical and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com