Climbing detection robot for transmission towers

A technology of power transmission towers and robots, applied in the directions of manipulators, manufacturing tools, etc., can solve the problems that the angle steel climbing of power transmission towers cannot be realized, the spatial structure of power transmission towers is not suitable, and the work efficiency is low. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

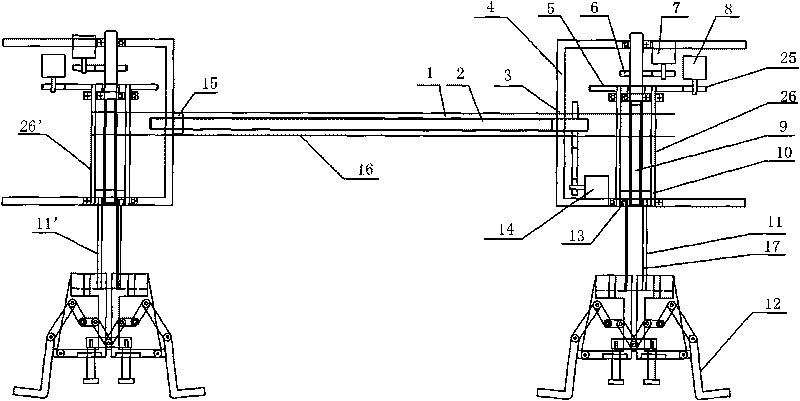

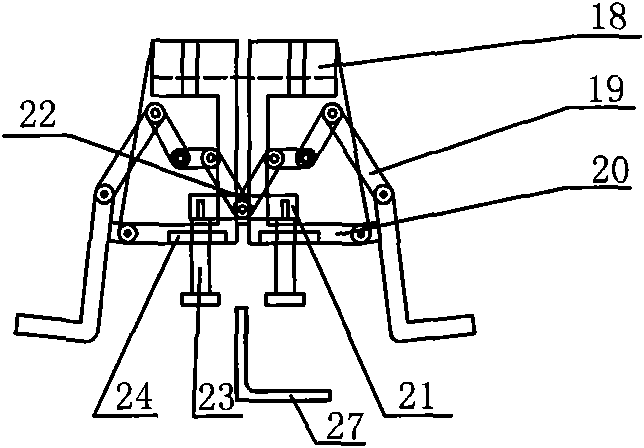

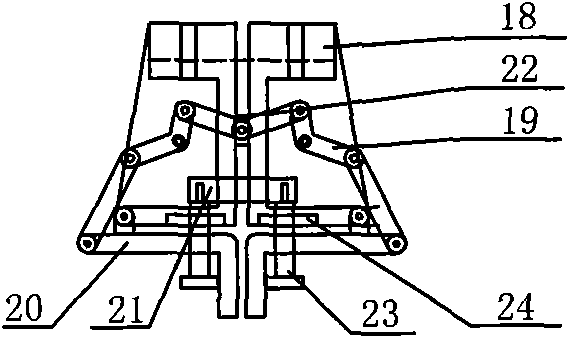

[0015] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a boom telescoping device 16, and the two ends of the boom telescoping device 16 are respectively provided with a manipulator device 11, 11'. The device 25 is connected, the lower end of the transmission device 26 is connected with the clamping device 12, and the detection device is installed in the box body 4, 4'.

[0016] In the boom telescoping device 16, the boom motor 14 is connected with the lead screw 2 through the gear set, the light rod 1 and the light rod cover are located on both sides of the box body 4, one end of the lead screw 2 is connected with the box body 4' through a nut 15, and the lead screw 2 The other end is connected with the box body 4 through the bearing 3.

[0017] In the transmission device 26, the main shaft 9 passes through the casing 4 and is threadedly connected with the small sleeve 17 with internal thread, the main shaft 9 is covered with a large sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com