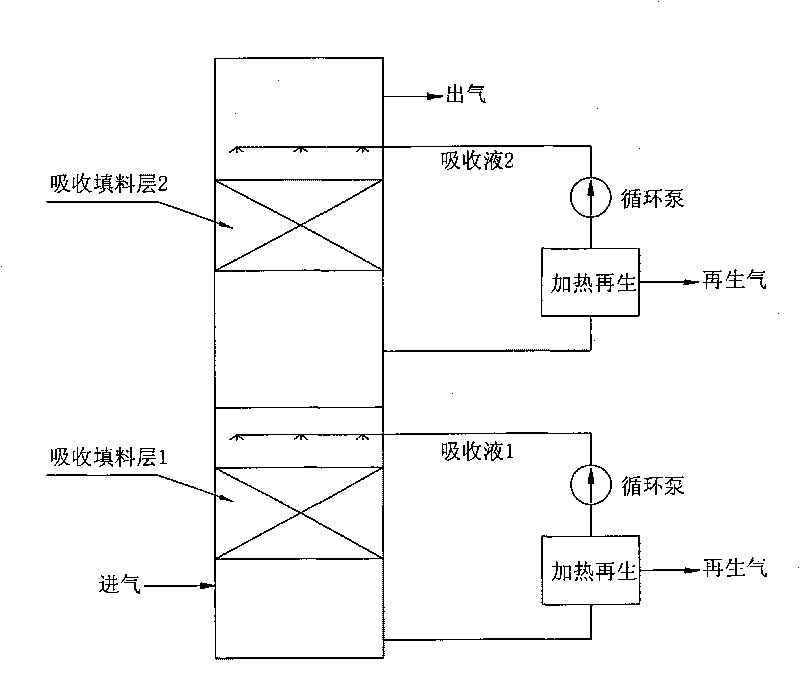

Bio-gas two-stage normal-pressure decarbonization device

A biogas and decarbonization technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of small biogas flow and cannot use medium-pressure decarbonization, and achieves low cost, simple structure, and convenient manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

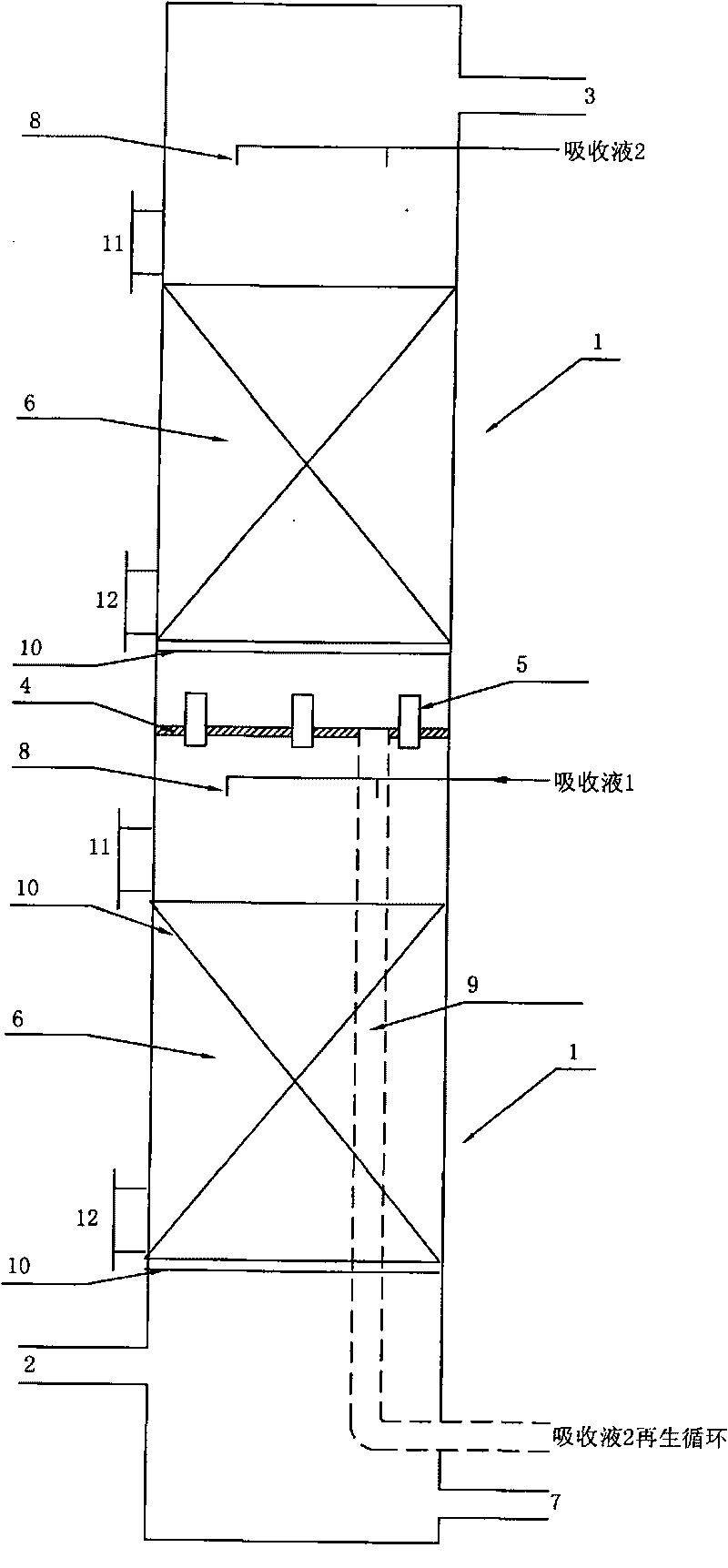

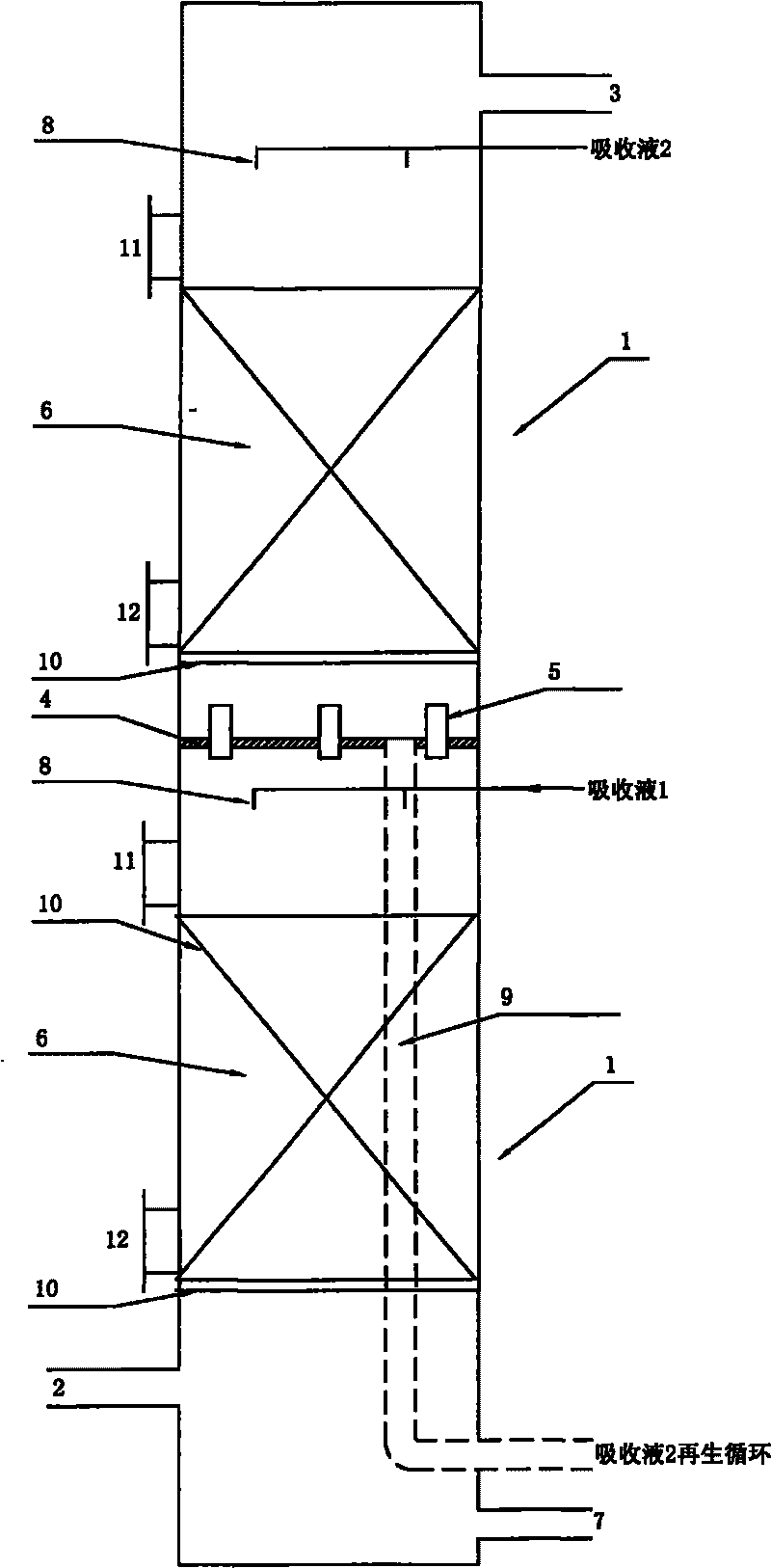

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] Such as figure 2 shown.

[0020] A two-stage atmospheric pressure decarburization device for biogas, which is composed of at least two stacked packed towers 1, figure 2 The two-layer structure adopted in the present embodiment is illustrated by taking a two-layer packed tower as an example, and the structure with more than two layers can be deduced by analogy, wherein the bottom of the packed tower 1 at the bottom is provided with a biogas inlet 2 and a bottom absorption liquid Regeneration circulation outlet 7, the packed tower 1 at the top is provided with a biogas outlet 3, and the upper part of the packed layer 6 of each packed tower 1 is provided with an absorption liquid spray pipe 8, wherein the absorption liquid in the upper packed tower 1 is sprayed The absorption liquid ejected from shower pipe 8 can be one or more combinations of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com