Smoke alkali-free adsorption type biological desulphurization technology

A biological desulfurization and adsorption technology, applied in the field of flue gas desulfurization technology, can solve the problems of expensive equipment and high maintenance technical requirements, and achieve the effect of reducing operating costs and eliminating secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

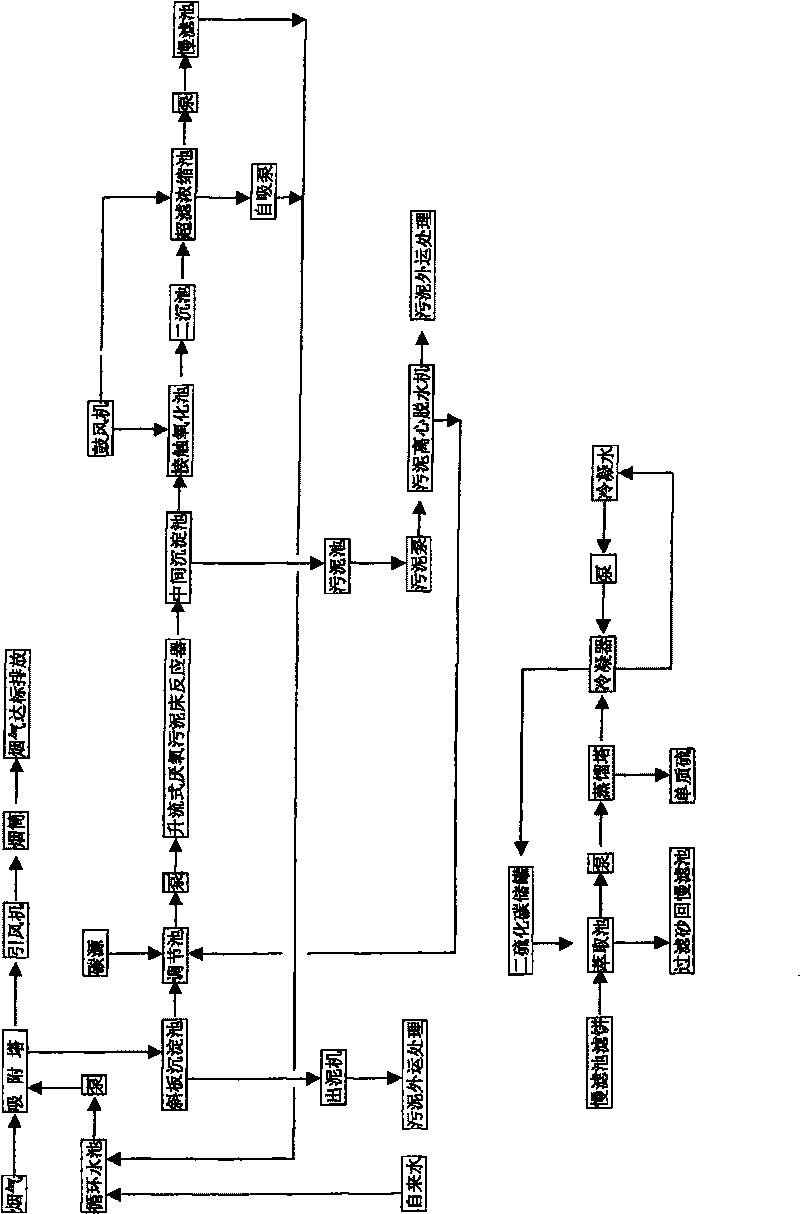

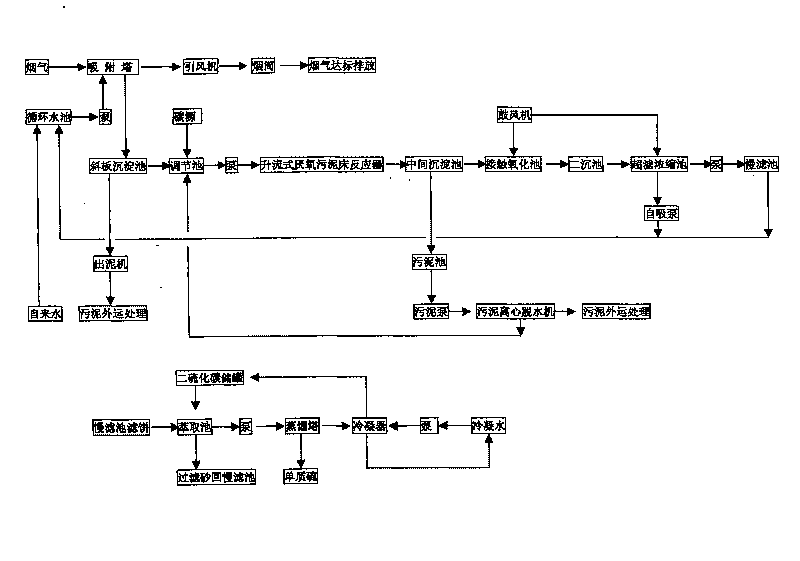

[0045] A flue gas non-alkali adsorption type biological desulfurization process, the process steps are as follows:

[0046] 1. Flue gas adsorption process:

[0047] The absorption liquid is stored in the circulating water pool, and enters the adsorption tower after being pressurized by the pump; the flue gas enters the adsorption tower through the pipeline, and is fully stirred and contacted with the absorption liquid at PH=7.0-8.0 to make the sulfur dioxide and trioxidation in the flue gas The sulfur is absorbed by the absorption liquid, and the desulfurized flue gas is discharged through the chimney under the power of the induced draft fan.

[0048] The absorption liquid that absorbs sulfur dioxide and sulfur trioxide is discharged from the adsorption tower to become desulfurization wastewater.

[0049] 2. Biological desulfurization process of desulfurization wastewater:

[0050] The desulfurization wastewater first enters the inclined plate sedimentation tank, and the sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com