Method for producing lightweight concrete product by flue gas desulfurization based on red mud

A lightweight concrete and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of environmental pollution, poor biodegradability, and high chemical oxygen demand concentration, to ensure high-efficiency operation, reduce Operating costs, avoiding the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] According to the formula in Table 1, mix the components uniformly to obtain a desulfurizer, then add alkaline wastewater to make a desulfurizer slurry, and send it to the desulfurizer. The flue gas (with an oxygen content of 18vol%) enters the desulfurization tower from the flue gas inlet of the desulfurization tower, and after passing through the three absorption spray layers of the desulfurizer slurry, the sulfur dioxide is fully absorbed by the desulfurizer slurry. After absorbing sulfur dioxide, the desulfurizer slurry is introduced into the slurry circulation tank in the lower part of the desulfurization tower by gravity. The slurry in the upper part of the slurry circulation tank in the tower is circulated to the three absorption spray layers, and the circulation volume of the three accounts for 50vt% of the total output. When the pH of the slurry in the lower part of the slurry circulation tank in the tower reaches 7.0, it is discharged as desulfurization slurry....

Embodiment 2

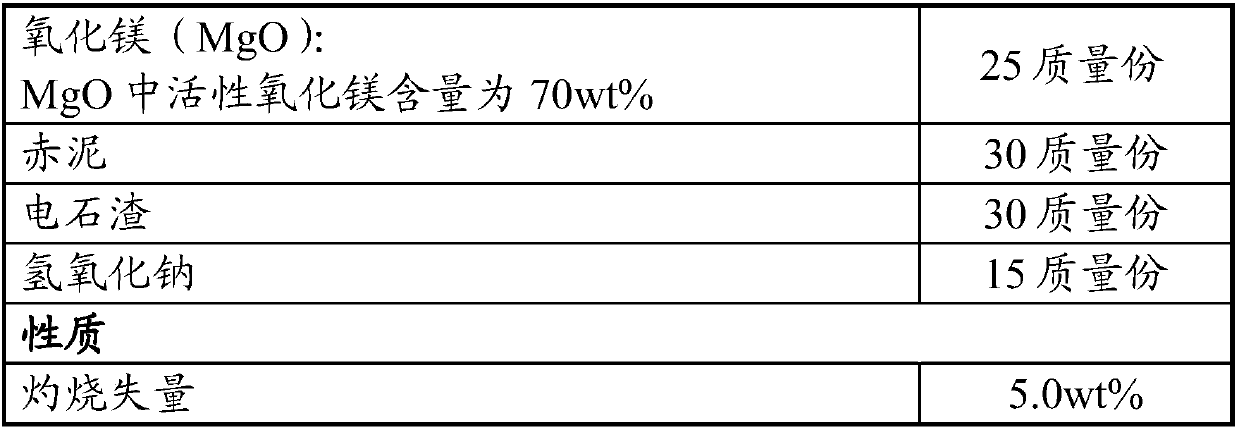

[0076] Table 7 and Table 8 below show the desulfurization agent formula and flue gas desulfurization working conditions in Table 6. All the other conditions are the same as in Example 1. See Table 9 for the recipe. See Table 10 for performance test results.

[0077] Table 6 Desulfurizer formula

[0078]

[0079] Table 7 Desulfurization working condition parameters

[0080] serial number

project

quantity

unit

1

Flue gas volume at the inlet of desulfurization tower (working condition)

492300

m 3 / h

2

Standard smoke volume

316352

N m 3 / h

3

Desulfurization tower inlet temperature

141

℃

4

SO2 inlet concentration

1428

mg / Nm 3

5

10

wt%

[0081] Table 8 Desulfurization Emissions

[0082] serial number

project

quantity

unit

1

Flue gas volume at the outlet of desulfurization tower (working condition)

3010...

Embodiment 3

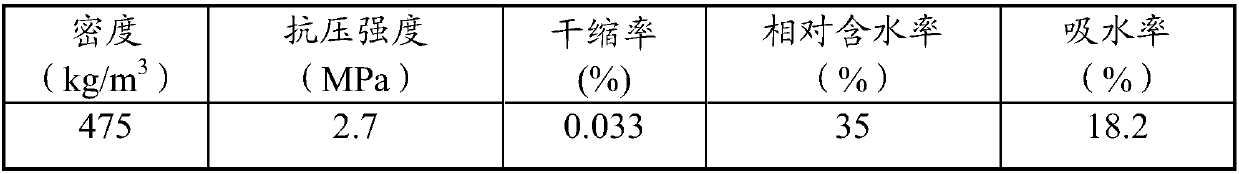

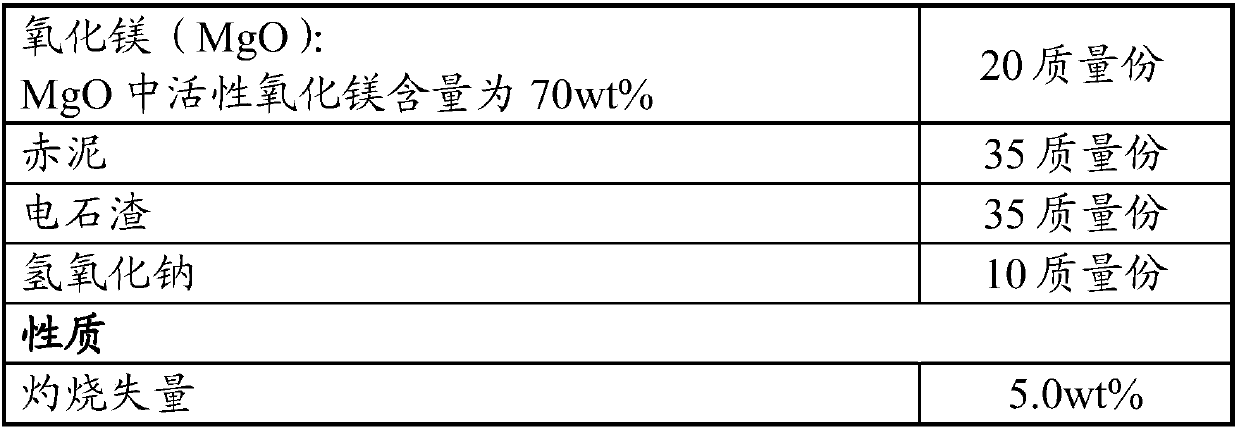

[0088]Table 12 and Table 13 below show the desulfurization agent formula and flue gas desulfurization working conditions in Table 11. All the other conditions are the same as in Example 1. See Table 14 for recipes. See Table 15 for performance test results.

[0089] Table 11 Desulfurizer formula

[0090]

[0091] Table 12 Desulfurization working condition parameters

[0092] serial number

project

quantity

unit

1

Flue gas volume at the inlet of desulfurization tower (working condition)

478000

m 3 / h

2

Standard smoke volume

295603

N m 3 / h

3

Desulfurization tower inlet temperature

150

℃

4

SO2 inlet concentration

1500

mg / Nm 3

5

10

wt%

[0093] Table 13 Desulfurization Emissions

[0094] serial number

project

quantity

unit

1

Flue gas volume at the outlet of desulfurization tower (working condition)

3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com