Enzymatic-process method for improving emulsifying property and gelation property of pea protein

A pea protein and gelling technology, which is applied in protein food processing, plant protein processing, protein food ingredients, etc., can solve problems such as harsh reaction conditions, difficulty in removing unreacted reagents, and failure of lysine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

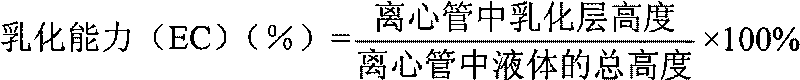

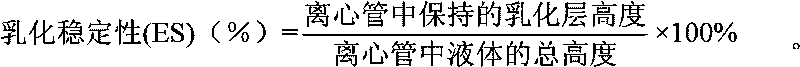

Image

Examples

Embodiment 1

[0025] Example 1: Adjust the pea protein into a pea protein slurry with a mass concentration of 10% according to the instructions; adjust the pH to 7.5, add transglutaminase 3U / g protein to the pea protein slurry, and perform enzymatic modification at 45°C for 2 hours Concentrate in vacuum to a mass concentration of 12%, and spray-dry at an inlet air temperature of 150°C and an outlet air temperature of 85°C to obtain pea protein with good gel properties. The specific results are shown in Table 1.

[0026] Table 1 Comparison of physical and chemical properties of pea protein before and after enzymatic modification

[0027]

Embodiment 2

[0028] Example 2: Adjust the pea protein into a pea protein slurry with a mass concentration of 5% according to the instructions; adjust the pH to 6.5, add transglutaminase 8U / g protein to the pea protein solution, and perform enzymatic modification at 40°C for 4 hours Concentrate in vacuum to a mass concentration of 12%, and spray dry at an inlet air temperature of 150°C and an outlet air temperature of 85°C to obtain pea protein with good emulsifying properties. The specific results are shown in Table 2

[0029] Table 2 Comparison of gel strength before and after pea protein gelation improvement by enzymatic method

[0030] Protein concentration (%)

8

10

12

14

16

18

Modified pre-pea protein coagulation

Rubber hardness (g)

0

0

0

0

29.2

44.7

modified pea protein

Rubber hardness (g)

65.5

310.7

382.1

477.4

601.9

723.3

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com