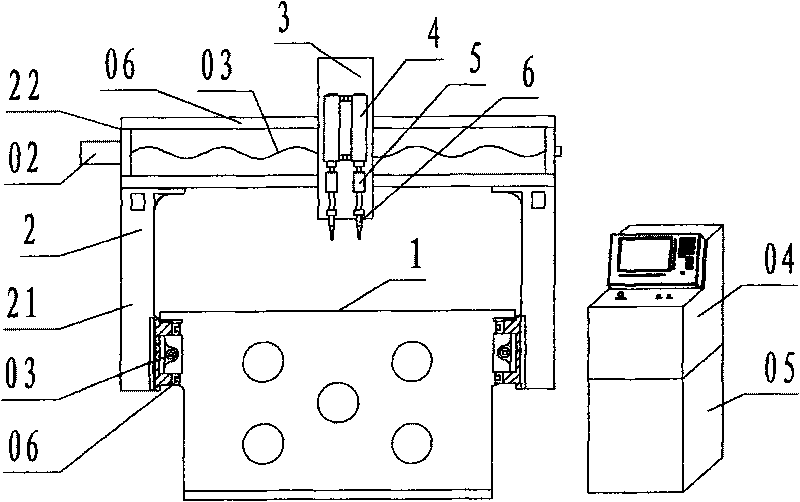

Portal frame movable type horizontal coordinate numerical control ultrasonic welding machine

A technology of ultrasonic welding and plane coordinates, which is applied in the field of CNC machine tools, can solve the problems of overuse of equipment, waste of processing equipment resources, low efficiency, etc., and achieve the effect of overcoming high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

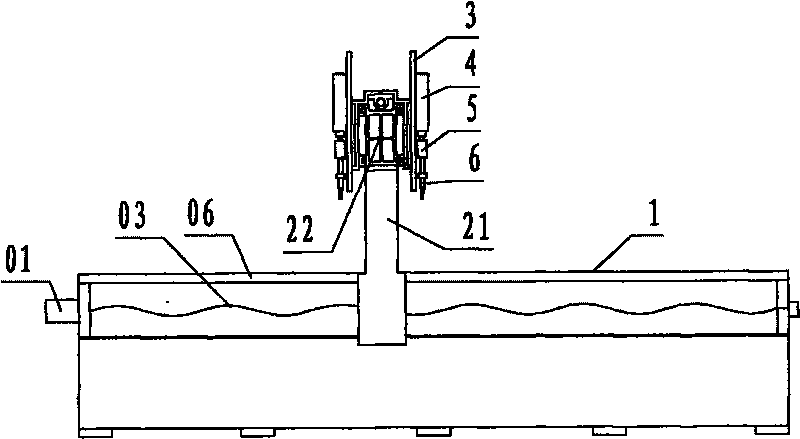

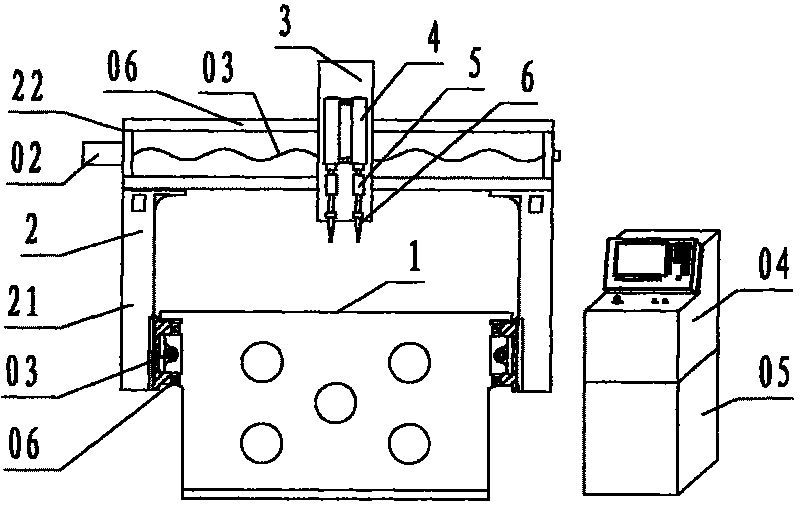

[0013] refer to Figure 1 ~ Figure 2 , a kind of gantry movable type plane coordinate numerical control ultrasonic welding machine tool of the present invention is a kind of special welding processing equipment combining ultrasonic welding machine and numerical control machine tool, including fixed workbench 1, mobile gantry 2, horizontal carriage 3, Cylinder 4, vibrator 5, welding head 6, Y-axis servo motor 01, X-axis servo motor 02, ball screw pair 03, numerical control system 04, ultrasonic generator 05, wherein: the fixed workbench 1 is a conventional machine tool The bed material is made of hollow rectangular box type, and the workbench is also the supporting part of the bed; the upper surface of the fixed workbench is a plane, and there are installation holes for setting fixtures on the plane, and the two longitudinal sides of the fixed workbench are provided with parallel, supporting parts. Guide the mobile gantry 2 to slide longitudinally, protruding grooved guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com