Preparing method of lotus paste puff pastry

A production method and lotus seed paste technology, applied in baking, baked goods, food science and other directions, can solve the problems of complex production process and single variety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

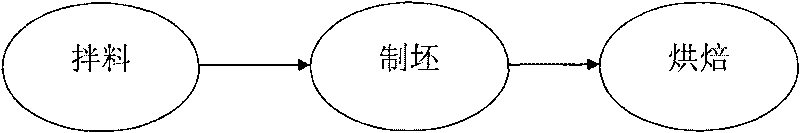

[0005] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings.

[0006] See Figure 1, firstly mix the flour and water in the cake skin material, then add cooked lard and mix well to make a dough; in addition, mix the pastry material well and knead thoroughly to form a ball. Next, make the cake base: take the pastry and wrap it into the skin (4:6 ratio), roll it up with a small roller, roll it up and fold it (three folds) into a ball, take 50 grams of semi-finished lotus seed paste and wrap it into the pastry, seal it and press it Flatten into cakes. If you want to make round edges with patterns, you can knead them into lace like making lace cakes. Final baking: oven temperature 190°C, about 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com