Heat dissipation equipment

A heat dissipation equipment and equipment technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve problems such as inability to adjust in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

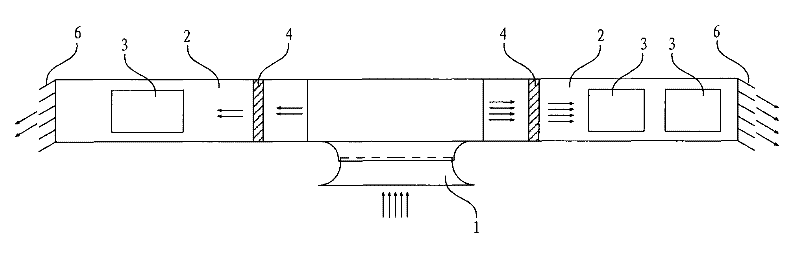

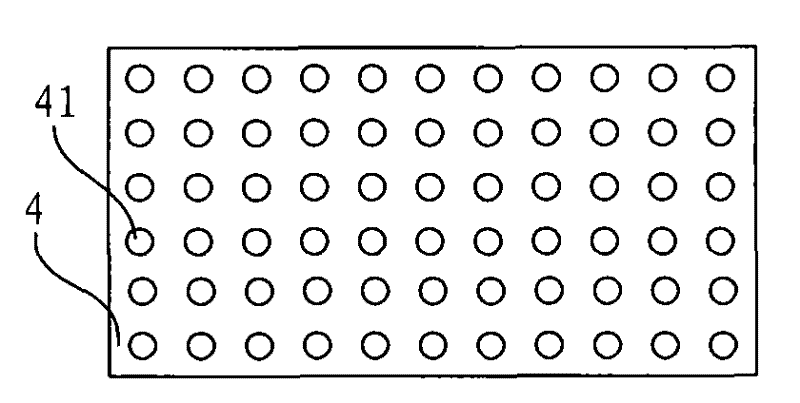

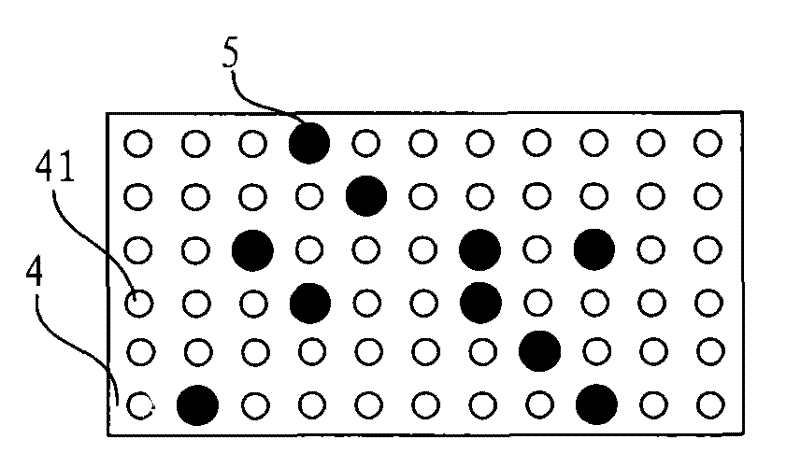

[0017] figure 1 A schematic structural diagram of a heat dissipation device provided in Embodiment 1 of the present invention, as shown in figure 1 As shown, the cooling device includes: a fan 1 , at least two cooling air ducts 2 communicating with the fan 1 , and an adjustable wind blocking plate 4 arranged at the air inlet of the cooling air duct 2 .

[0018] The heat dissipation air duct 2 is used for placing at least one heat generating component 3 . The number of cooling air ducts 2 may be multiple, and in this embodiment, two cooling air ducts 2 are taken as an example for illustration. Specifically, the cooling air duct 2 may be a sealed cooling air duct.

[0019] The fan 1 is used to provide the cooling air duct 2 with wind for reducing the temperature of the heat generating component 3 . The fan 1 can pump the wind into each cooling air duct 2, specifically because the air inlet of each cooling air duct 2 is connected with the fan 1, so the fan 1 can pump the wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com