Rotor rubbing test device

An experimental device and rubbing technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of easily damaged shafts, which have not been well solved, and the simulation of rotating and static bumping faults is large, so as to achieve easy replacement and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

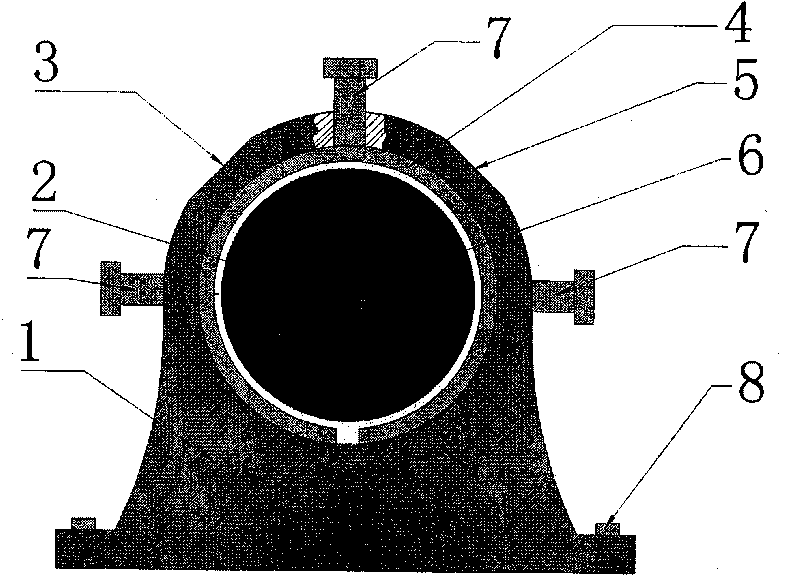

[0015] exist figure 1 In the front view of the rubbing device of the present invention, it mainly includes a support (1), a stator snap ring (4), a rotating member (6), a rubbing bolt (7) and a fastening bolt (8). The device is fixed on the test bench by fastening bolts (8) on the support (1), and is operated together with other components on the test bench to complete the experiment.

[0016] In the device, the rotating member (6) is connected with the rotating shaft (2) in an interference fit manner. It can be a disc or other rotating parts such as a turbine or impeller and is very easy to replace.

[0017] Stator snap ring 4 adopts copper material to make, and it is non-full circumference, but has the slit of certain width, is clearance fit between it and the rotating part, and its internal diameter is slightly larger than rotating part out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com