Variable air volume type air intake branch pipe

A technology of intake manifold and intake elbow, applied in combustion air/combustion-air processing, engine components, engine control, etc., can solve problems such as affecting engine performance, increasing intake resistance, and enhancing airflow inertia. Achieve the effect of improving power, small air intake resistance and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

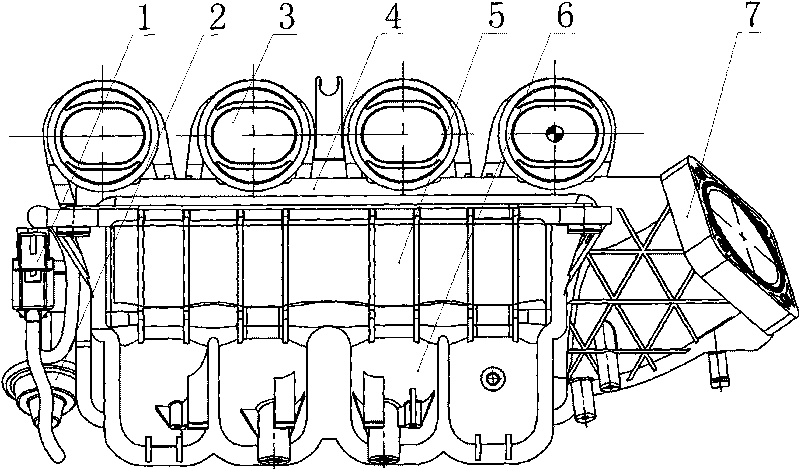

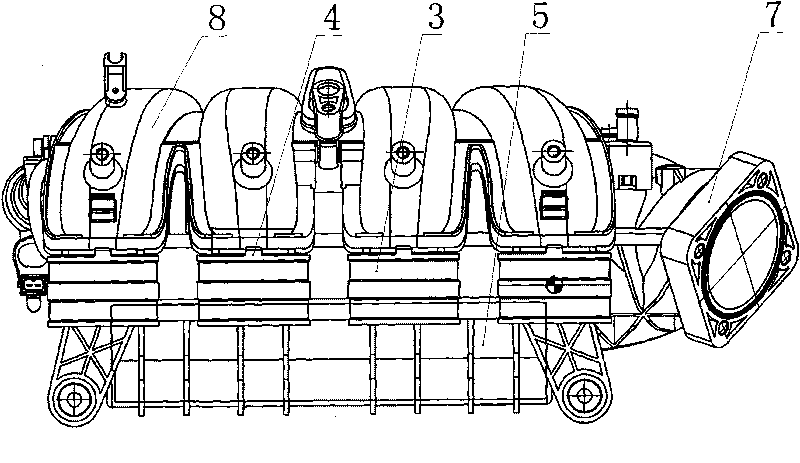

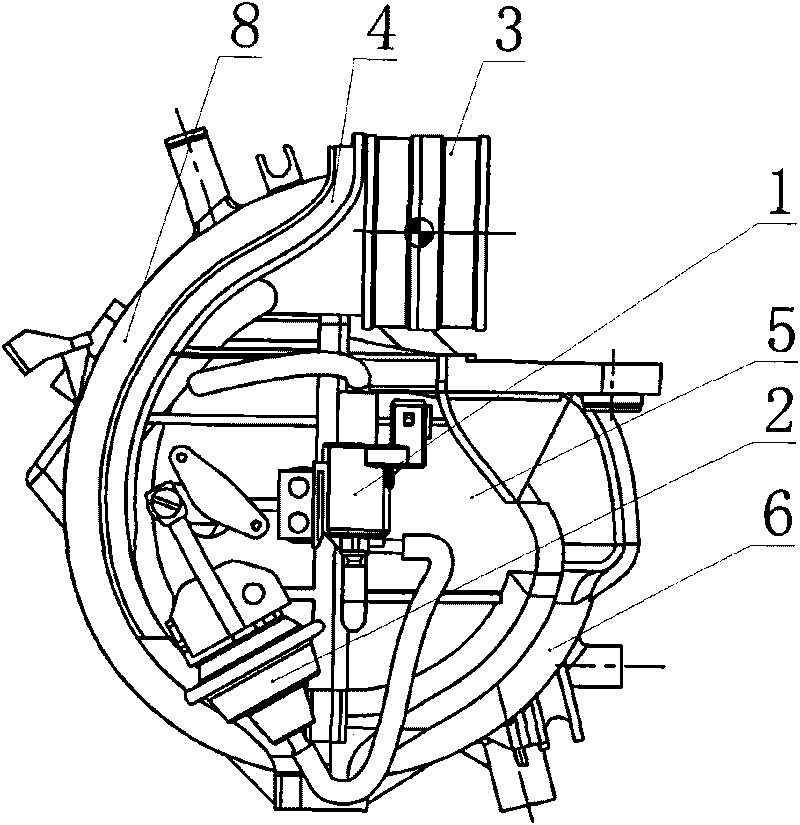

[0022] A variable air intake manifold, which is composed of an upper piece 8, a middle piece 4, a lower piece 5, and a lower two pieces 6. The upper piece, the middle piece, the lower one, and the lower two pieces are interlocked to form the intake manifold Tube, an intake elbow 7 is formed on one side of the intake manifold; a pressure stabilizing chamber is formed between the middle piece and the lower one and the lower two pieces; a number of outlet pipes 3 are formed on the middle piece (in this embodiment, four ), a number of air inlets 18 corresponding to the air outlet pipe are formed on the middle plate in the pressure-stabilizing chamber, and a number of channels 17 are formed between the upper plate and the middle plate, and the plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com