Multi-element aerogel composite material and preparation method thereof

A composite material and multi-component technology, applied in the field of airgel composite materials and its preparation, can solve the problems of high brittleness of the heat insulation layer and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

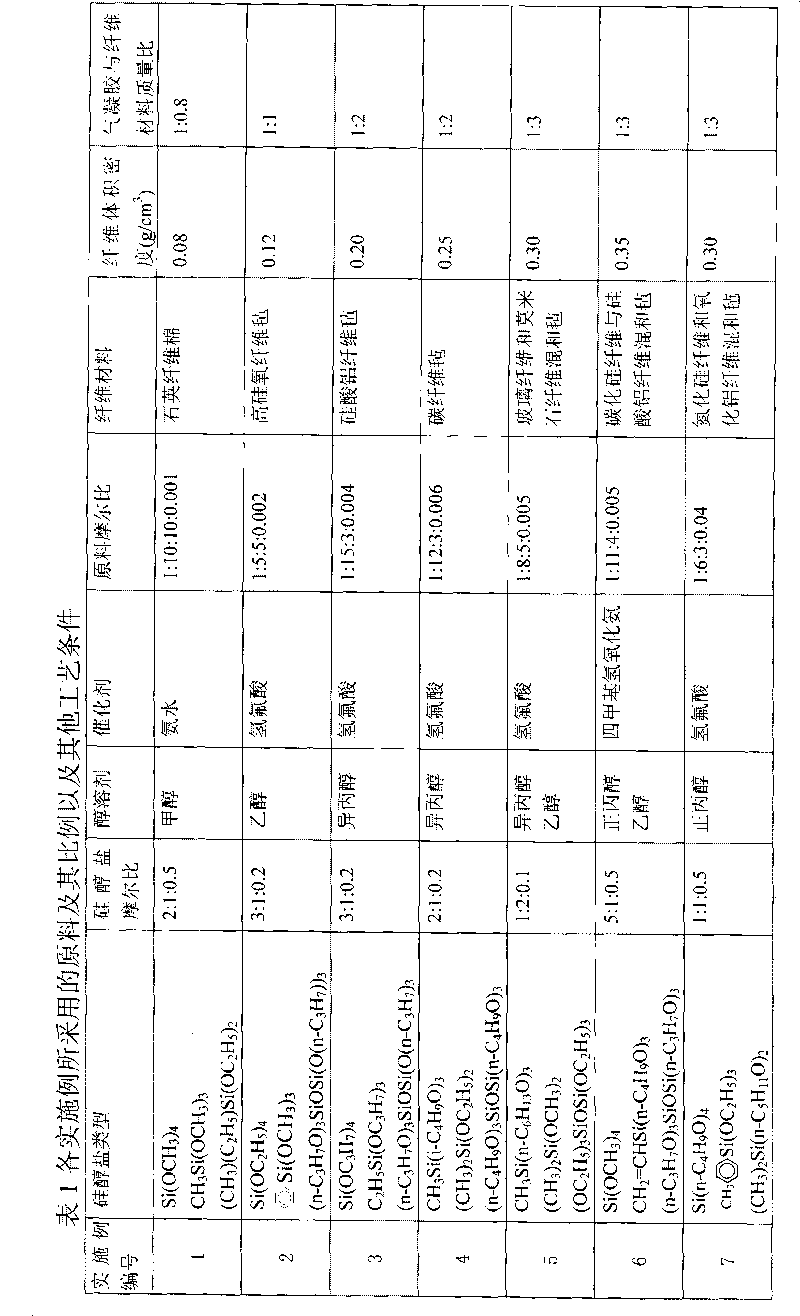

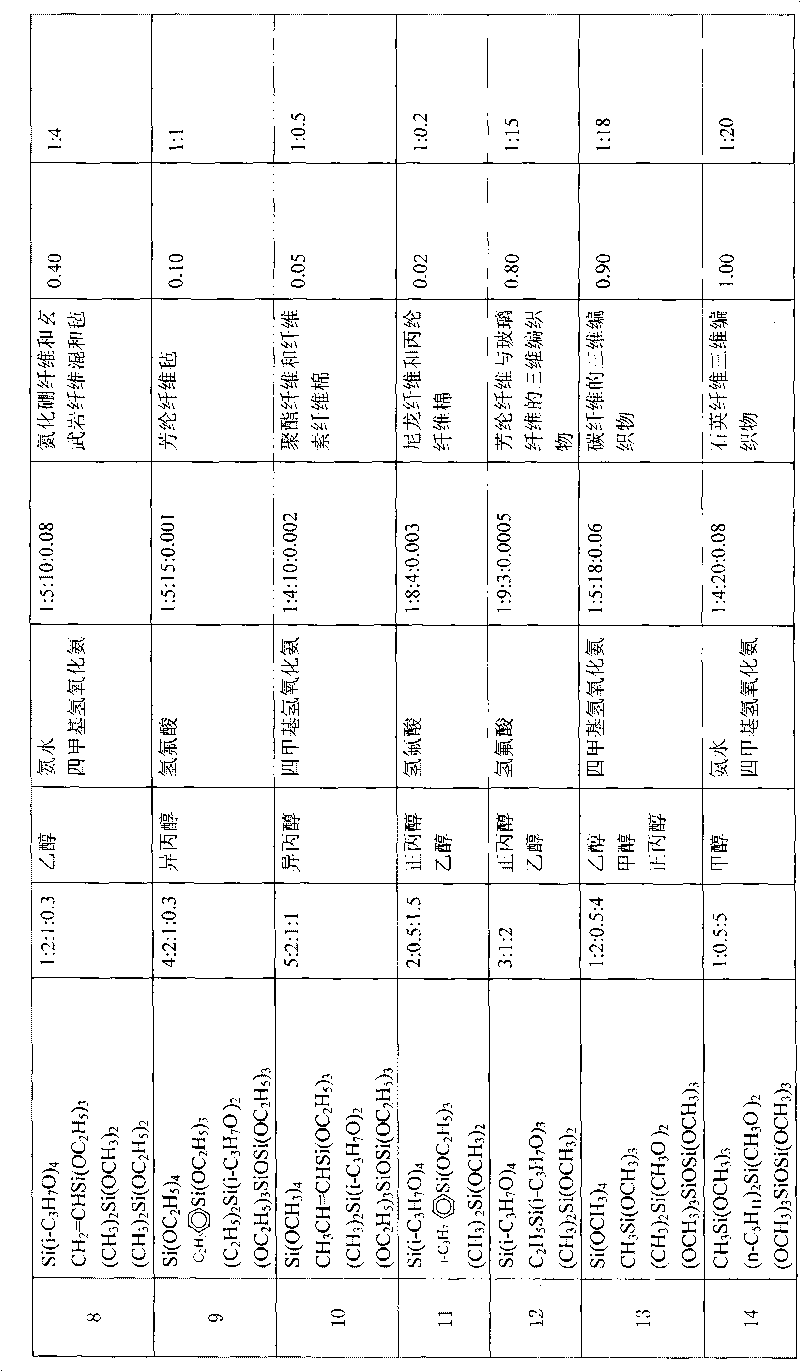

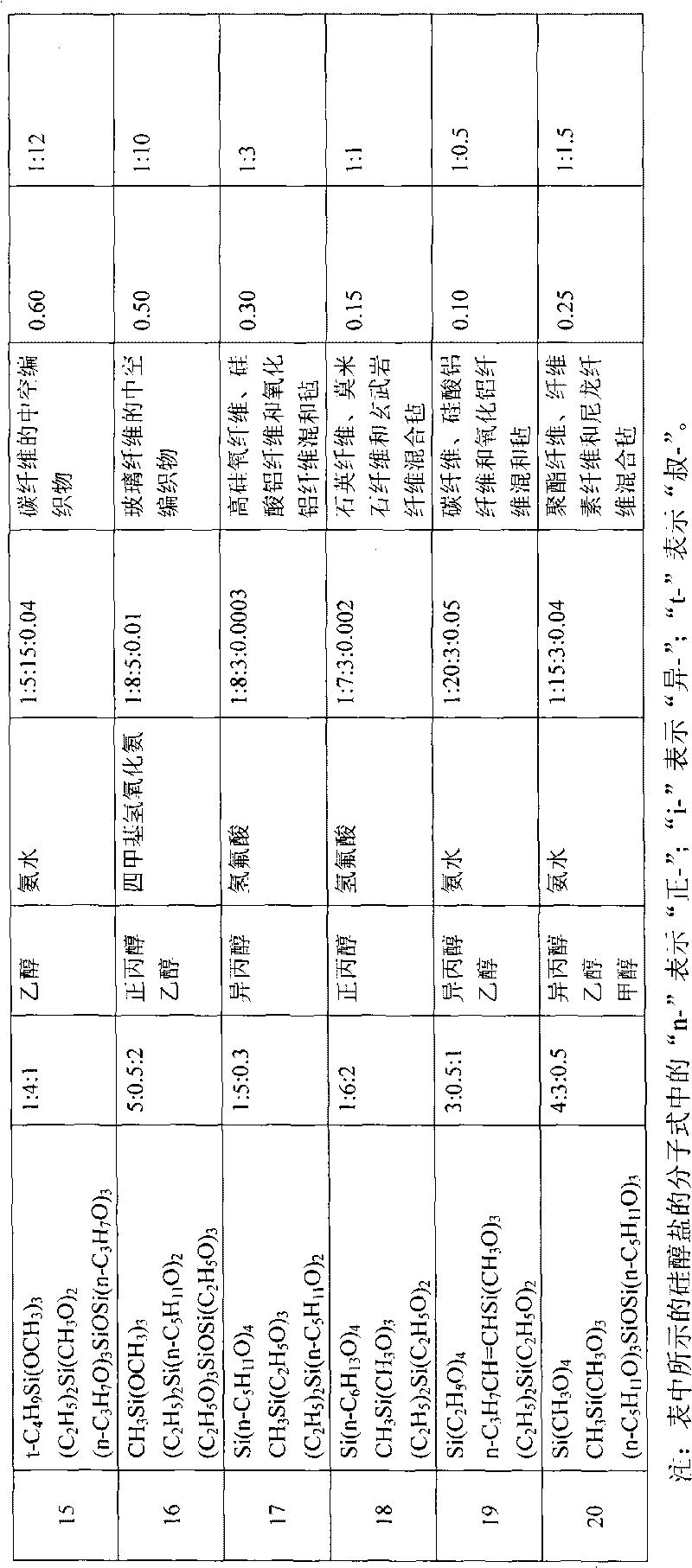

Examples

Embodiment 1

[0106] Add methanol as alcohol solvent and silicon alkoxide Si(OCH 3 ) 4 , silicon alkoxide CH 3 Si(OCH 3 ) 3 and silicon alkoxide (CH 3 )(C 2 h 5 )Si(OC 2 h 5 ) 2 Mix well with deionized water, then add ammonia water as a catalyst, and mix well to obtain silica sol. The molar ratio of silicon alkoxide, alcohol solvent, deionized water and catalyst is 1: 10: 3: 0.01, wherein the molar number of silicon alkoxide is used silicon alkoxide Si (OCH 3 ) 4 , silicon alkoxide CH 3 Si(OCH 3 ) 3 and silicon alkoxide (CH 3 )(C 2 h 5 )Si(OC 2 h 5 ) 2 The sum of moles; the silicon alkoxide Si(OCH 3 ) 4 , silicon alkoxide CH 3 Si(OCH 3 ) 3 and silicon alkoxide (CH 3 )(C 2 h 5 )Si(OC 2 h 5 ) 2 The molar ratio is 2:1:0.5.

[0107] Impregnate the quartz fiber cotton with the prepared silica sol, the impregnation method adopts the method (a) described herein to carry out, that is, directly add the silica sol to the mold cavity that is equipped with the quartz fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com