Chemical preparation method of metal cobalt nanowire

A technology of cobalt nanowires and metal cobalt, which is applied in the field of preparation of metal cobalt powder, can solve the problems of large powder particles, long reaction time, poor shape controllability, etc., and achieve simple process, mild reaction conditions and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of reaction solution:

[0024] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0025] CoCl 2 0.013mol / L

[0026] NaOH 0.05mol / L

[0027] PVP k30 10.0g / L

[0028] Reaction temperature 50°C

[0029] Magnetic stirring time 20 minutes

[0030] 2. Cobalt nanowire preparation:

[0031] ①Heat the solution prepared by the above method to 140°C;

[0032] ② Add hydrazine hydrate 50ml / L dropwise;

[0033] ③React for 20 minutes until the reaction is complete;

[0034] ④ centrifugal separation solution and cobalt nanowire;

[0035] ⑤ Wash the cobalt nanowires 3 times with absolute ethanol;

[0036] ⑥ dry collection.

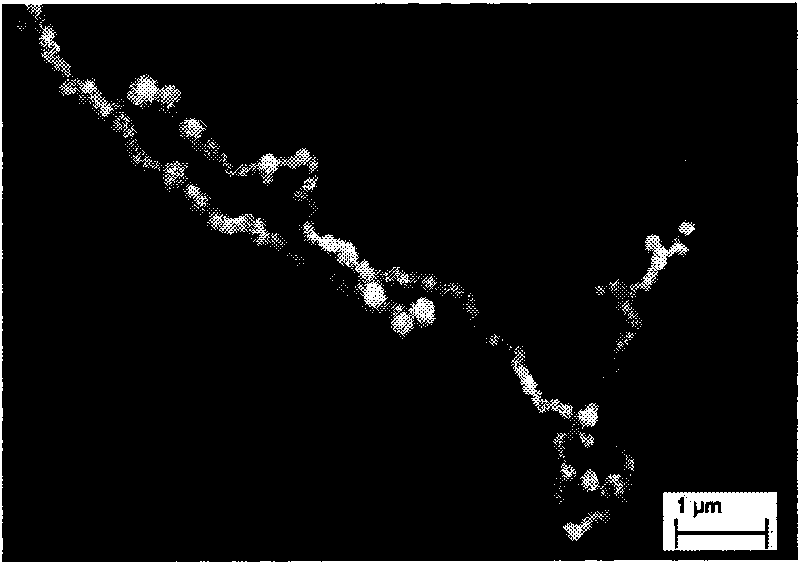

[0037] Nano cobalt powder with an average length of 5.0 μm, an average diameter of 200 nm and an aspect ratio of 25 was obtained. It looks like figure 1 shown.

Embodiment 2

[0039] 1. Preparation of reaction solution:

[0040] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0041] CoCl 2 0.05mol / L

[0042] NaOH 0.05mol / L

[0043] PVP k30 10.0g / L

[0044] Reaction temperature 50°C

[0045] Magnetic stirring for 20 minutes

[0046] 2. Preparation of cobalt nano powder:

[0047] ① Place the solution prepared by the above method in a water bath at 95°C;

[0048] ② Add hydrazine hydrate 20ml / L dropwise

[0049] ③React for 30 minutes until the reaction is complete;

[0050] ④ centrifugal separation solution and cobalt nanowire;

[0051] ⑤ Wash the cobalt nanowires 3 times with absolute ethanol;

[0052] ⑥ dry collection.

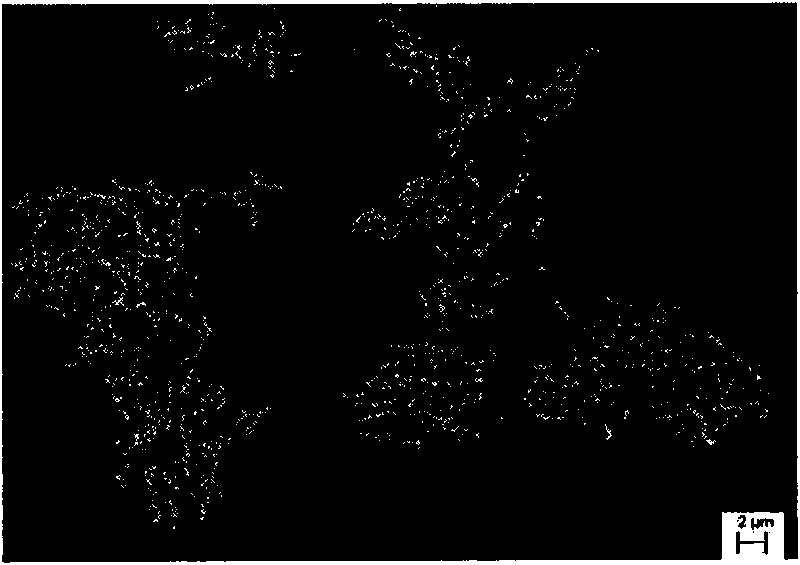

[0053] Nano cobalt powder with an average length of 6 μm, an average diameter of 250 nm, and an aspect ratio of 24 was obtained. It looks like figure 2 shown.

Embodiment 3

[0055] 1. Preparation of reaction solution:

[0056] Use ethylene glycol as solvent to prepare solutions in the following proportions.

[0057] CoSO 4 0.02mol / L

[0058] NaOH 0.04mol / L

[0059] PVP k90 10.0g / L

[0060] Reaction temperature 60°C

[0061] Magnetic stirring for 30 minutes

[0062] 2. Preparation of cobalt nano powder:

[0063] ①Heat the solution prepared by the above method to 120°C;

[0064] ② Add hydrazine hydrate 30ml / L dropwise;

[0065] ③ React for 20 minutes;

[0066] ④ centrifugal separation solution and cobalt nanowire;

[0067] ⑤ Wash the cobalt nanowires 3 times with absolute ethanol;

[0068] ⑥ dry collection.

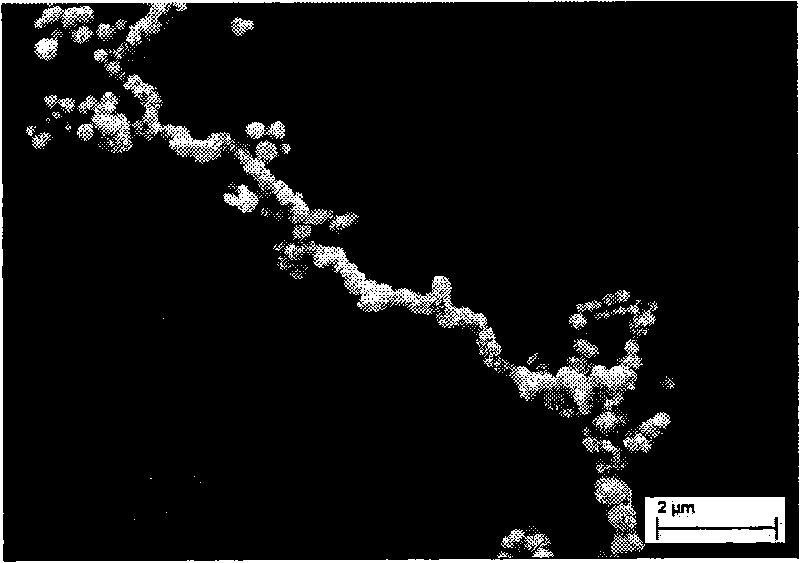

[0069]Nano cobalt powder with an average length of 2.0 μm, an average diameter of 163 nm and an aspect ratio of 13.4 was obtained. It looks like image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com