Solar cell

A technology of solar cells and top cells, applied in the field of solar cells, can solve the problems of high technical and process complexity, high photo-induced degradation rate of cells, complicated cell process, etc., achieve low photo-induced degradation rate and reduce photo-induced degradation rate , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

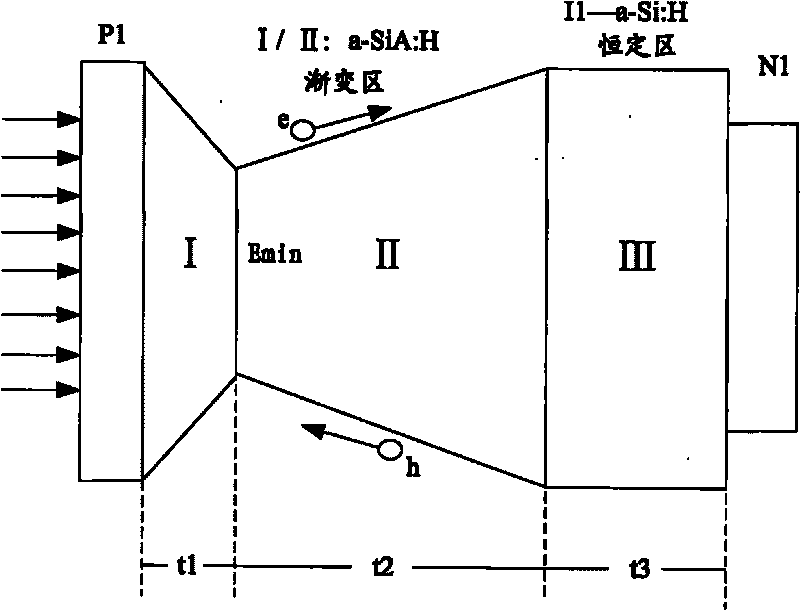

[0020] In the embodiment of the present invention, the band gap is gradually changed in the I layer of the top battery unit of the double-junction laminated battery, and the thickness of the I layer is reduced by reducing the band gap, thereby reducing the light-induced degradation rate and improving the stability of the battery.

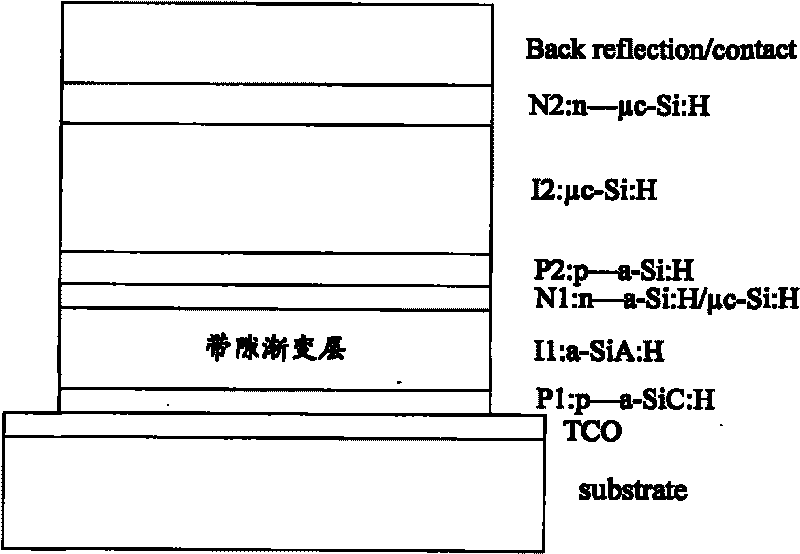

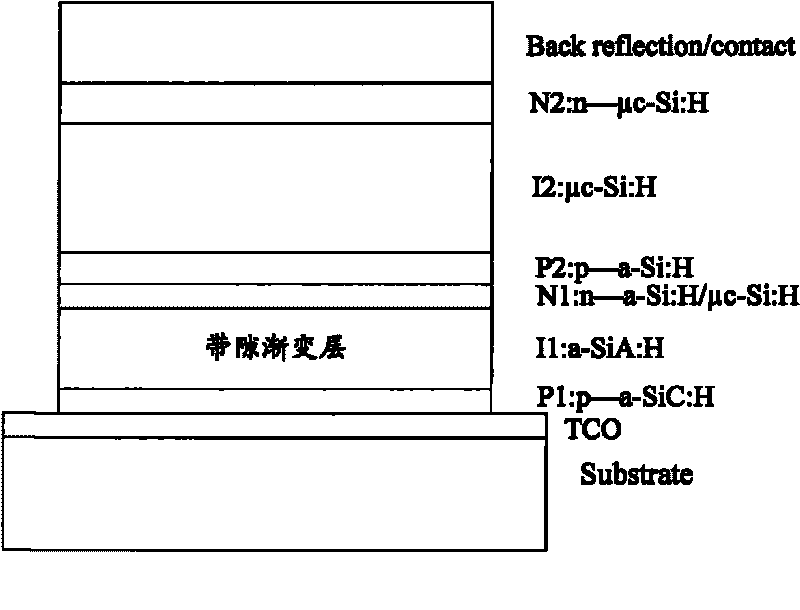

[0021] see figure 1 , the solar cell in this embodiment includes two cells, a top cell and a bottom cell. The top cell includes the material a-Si:H, and may also include the alloy a-SiA:H (A represents elements such as Ge, C, O, etc.), and the bottom cell includes the material μc-Si:H. The top cell includes a P1 layer, an I1 layer, and an N1 layer. The bottom cell includes a P2 layer, an I2 layer, and an N2 layer. The solar cell also includes a transparent conductive film (TCO), a back reflection electrode (Back reflection / contact) and a substrate (Substrate).

[0022] The I1 layer is a graded band gap layer. In this embodiment, the thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com