Method for detecting positional deviation among layers of multilayer printed circuit board

A printed circuit board, inner layer technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high time-consuming and cost, unable to represent the degree of alignment, unfavorable and accurate judgment of the degree of alignment, etc. Improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the present invention easier to understand, the present invention will be further described in conjunction with the accompanying drawings, but the embodiments in the accompanying drawings do not constitute any limitation to the present invention.

[0029] The invention relates to a manufacturing method of a multilayer printed circuit board, in particular to a judging method for judging whether the positions between layers are shifted during the manufacturing process of the multilayer printed circuit board. It can meet the interlayer offset judgment requirements of all products.

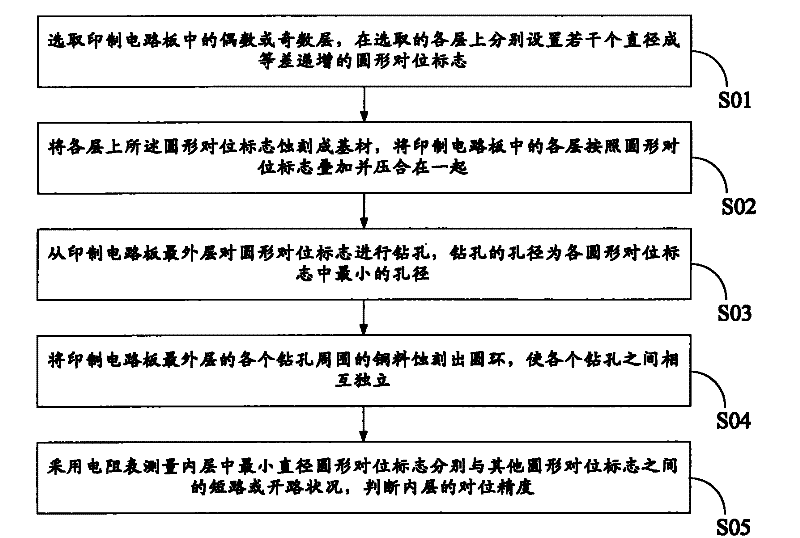

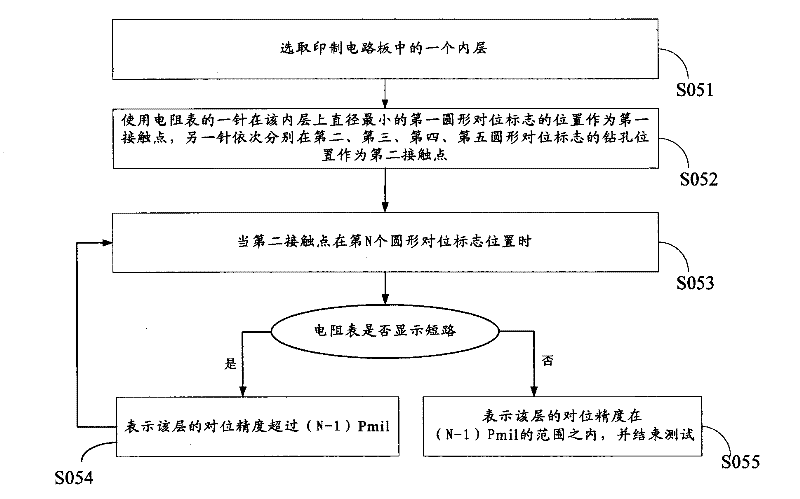

[0030] figure 1 A flow chart of a method for detecting position deviation between layers of a multilayer printed circuit board according to an embodiment of the present invention is shown.

[0031] The method includes the following steps:

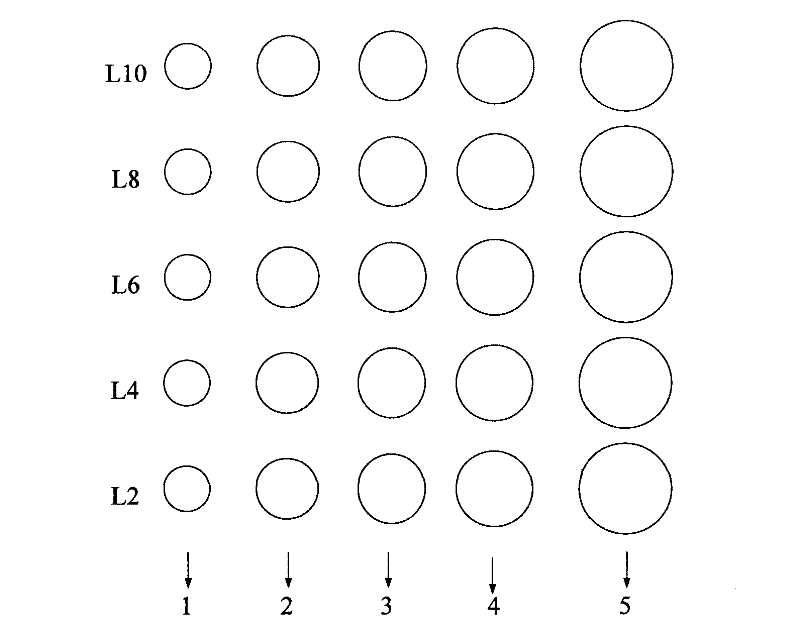

[0032] Step S01, select the even-numbered or odd-numbered layers in the printed circuit board, and set a number of circular alignment mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com