Device for testing performance of automotive steering system

A technology of automobile steering system and test device, which is applied in the field of performance test device of automobile steering system, can solve the problems that the test cannot completely simulate the steering gear, the error of the test parameters is large, and the difference in the working process is large, so that the test results are true and reliable, The effect of accurate and reliable position and convenient test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

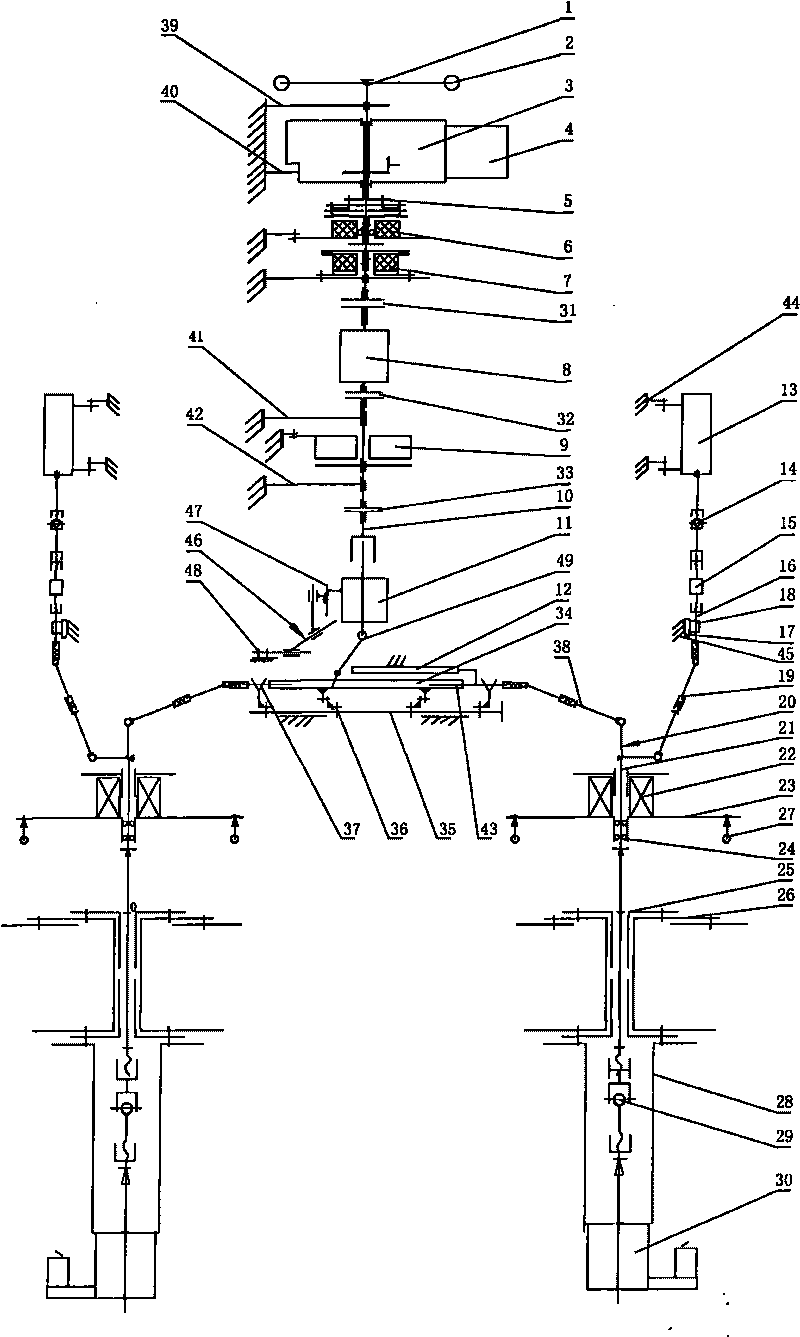

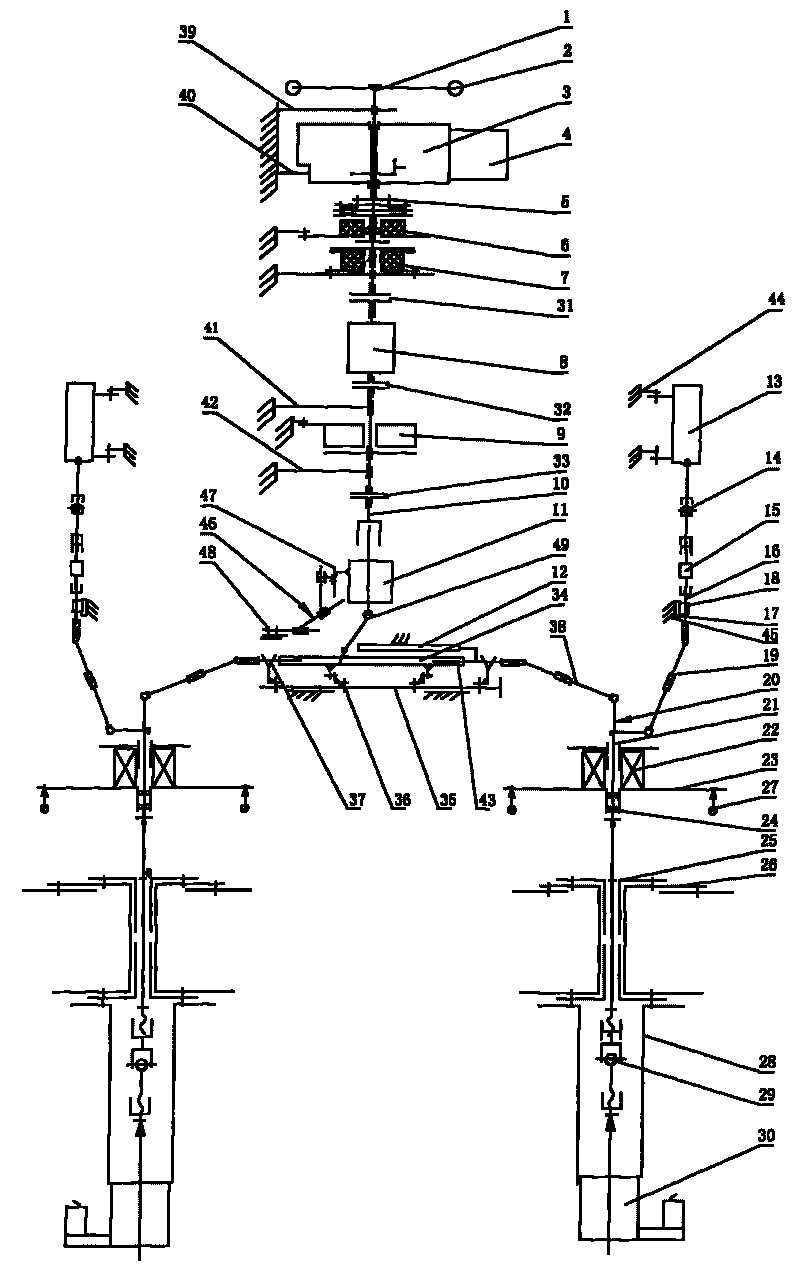

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Accompanying drawing is a structural representation of the present invention, as shown in the figure: automobile steering system performance test device comprises steering simulation system, axial loading system, suspension simulation system and automobile steering system, and axial loading system passes BELL mechanism 20 (being steering knuckle ) transmits the applied loading force of the axial loading system to the rack shaft 43 of the automobile steering system (consisting of the steering column 11, the steering universal joint 49, the steering gear 34, the tie rod 38 and the simulated steering knuckle). The BELL mechanism 20 is composed of two rods of equal length fixedly connected at 90°. One end of the BELL mechanism 20 is connected to the steering gear 34 through the ball joint and the tie rod 38 in turn, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com