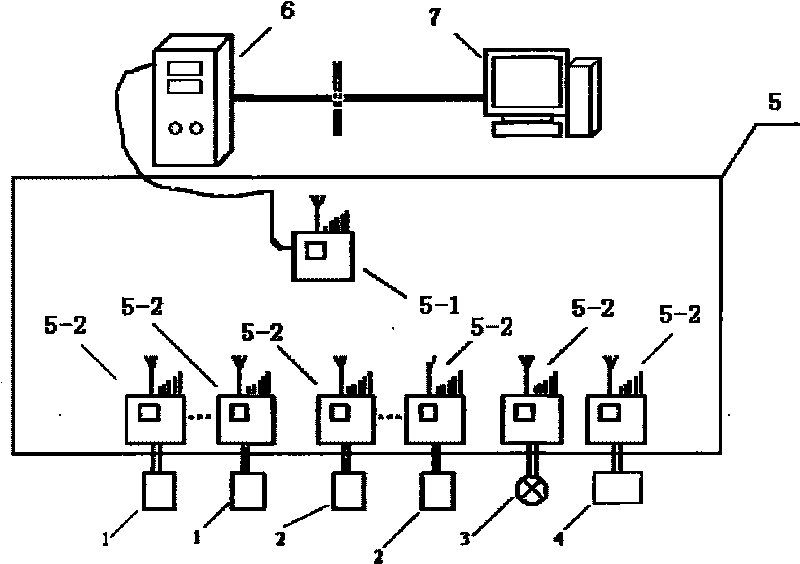

Accident monitoring method in welldrilling process

A kind of accident and drilling technology, which is applied in drilling equipment, automatic drilling control system, earthwork drilling and production, etc. It can solve the problem of failure to consider the amount of mud disturbance, the inability to obtain the abnormal change of circulating mud, and the inability to ensure the accuracy of overflow leakage alarm Reliability and other issues, to achieve the effect of accurate and reliable leakage alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

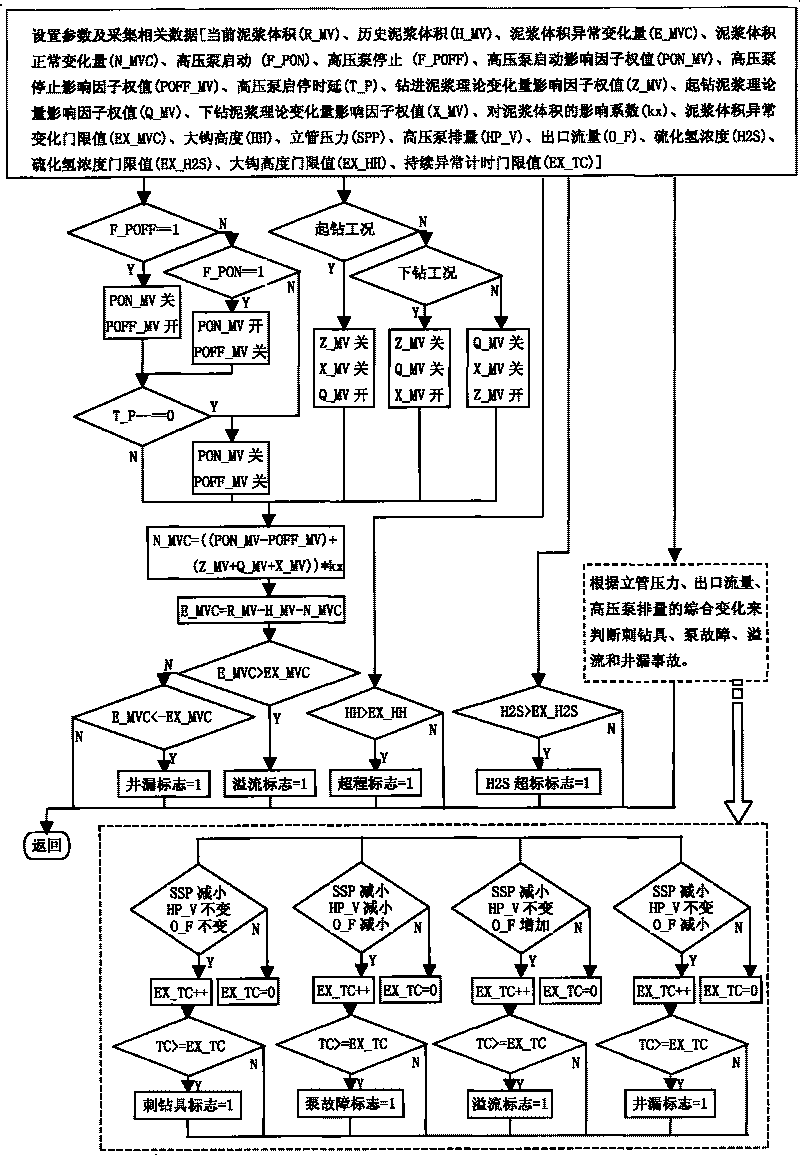

[0022] A method for monitoring accidents in the drilling process. The accidents include lost circulation and overflow. The difference is that the alarm judgment of the lost circulation and overflow is based on the total volume of mud in the circulating mud tank through the working condition identification model and the alarm model. The abnormal changes of the mud are monitored, and when the change of the total volume of the mud exceeds the alarm threshold value of lost circulation or overflow, a corresponding alarm is given.

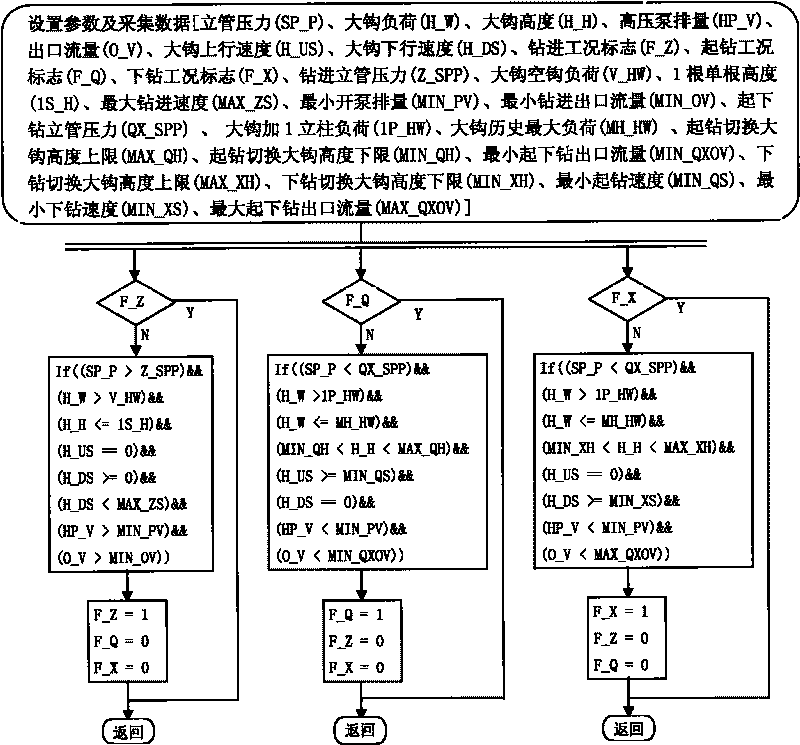

[0023] Specifically, the working condition recognition model automatically recognizes three working conditions of drilling, tripping out and tripping in through analyzing and processing drilling parameters.

[0024] Specifically, the interlocking among the three working conditions is realized through working condition flags, and the data processing model is automatically switched according to the detected switch between the working conditions.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com