Beating-up mechanism of non-circular gear planetary gear system

A planetary gear train and non-circular gear technology, applied in the field of weft beating mechanism of looms, can solve the problems of high machining accuracy, many hinge points, large cumulative error, etc., and achieve the effect of compact structure and short transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

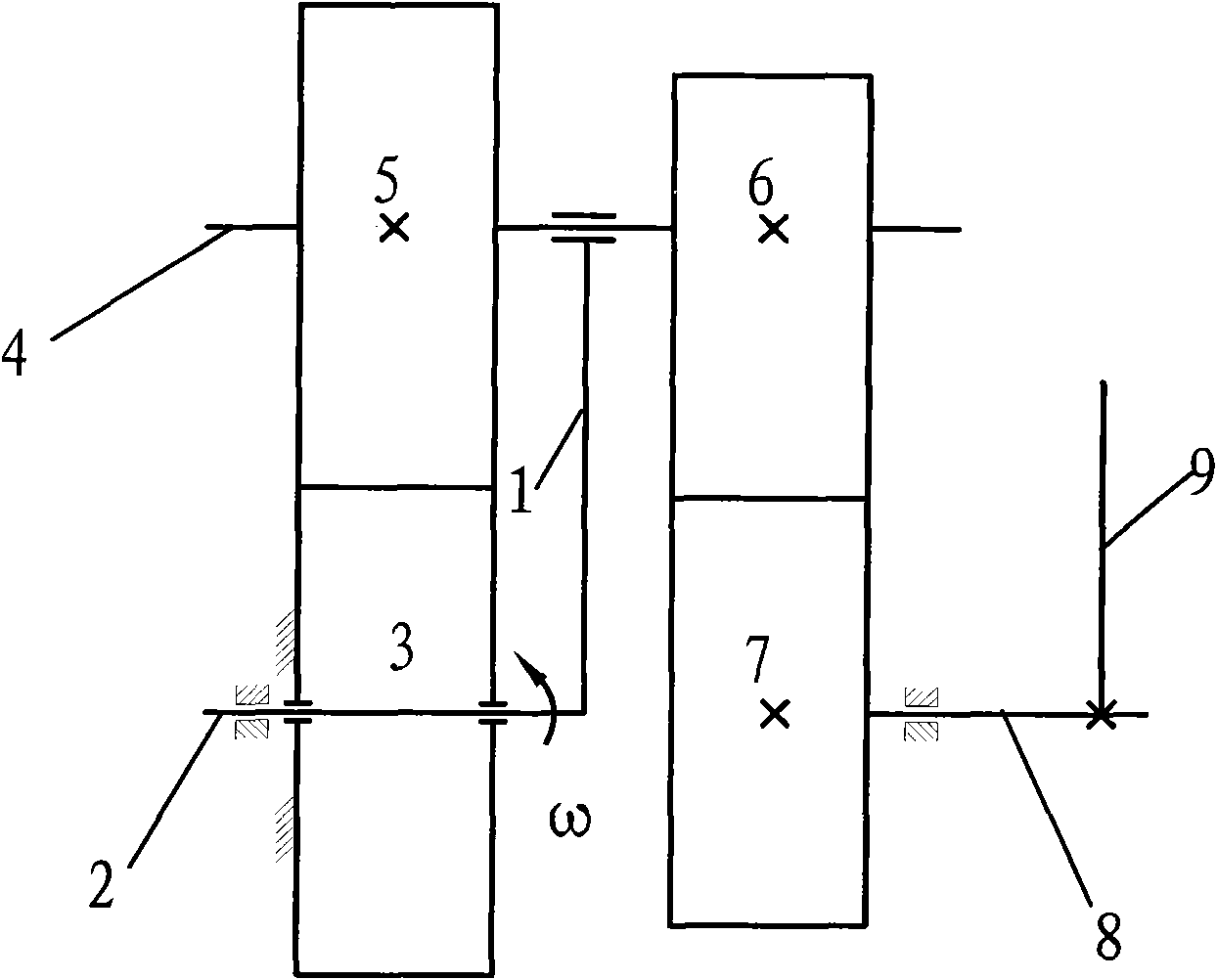

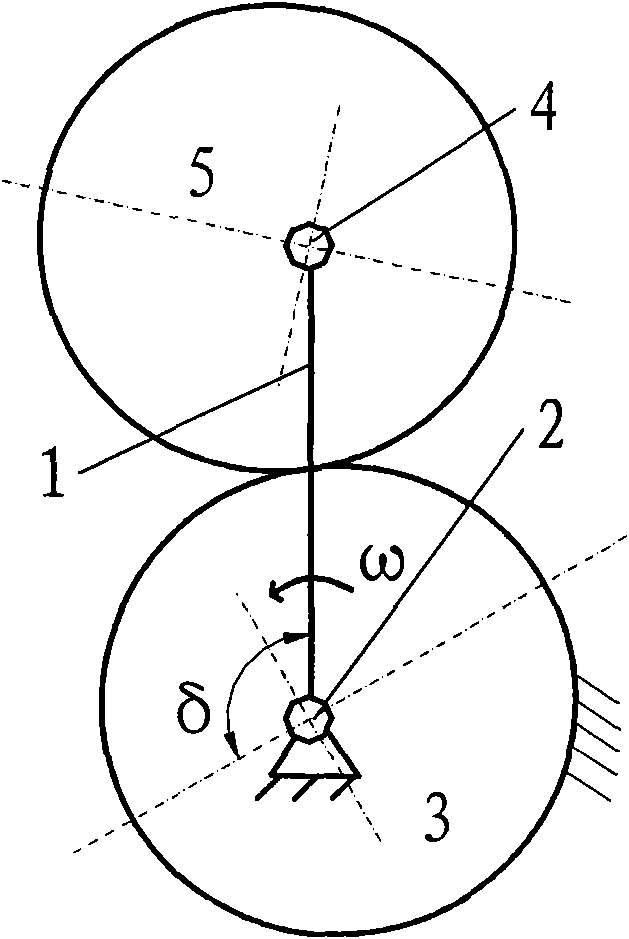

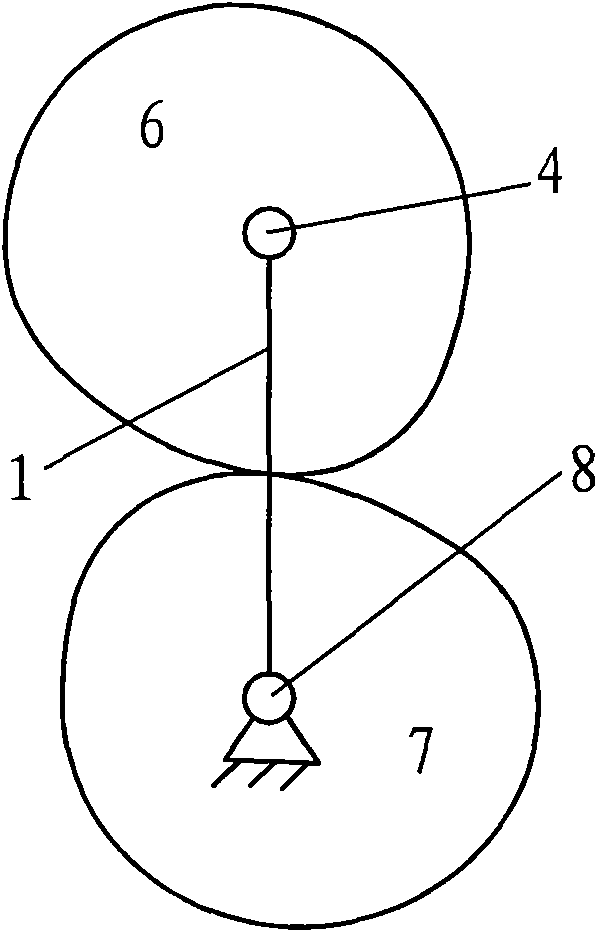

[0019] like figure 1 As shown, the planet carrier 1 of the present invention is driven by the main shaft 2 of the loom, the active non-circular sun gear 3 is looped on the main shaft 2 of the loom, and the active non-circular sun gear 3 does not move. The planetary shaft 4 is driven by the planet carrier 1, and the driven non-circular planetary gear 5 and the driving non-circular planetary gear 6 are fixed on the planetary shaft 4 respectively, and the driven non-circular planetary gear 5 and the driving non-circular The circular planetary gear 6 meshes with the driven non-circular sun gear 7, the driven non-circular sun gear 7 is fixed on the rocking shaft 8 (ie output shaft), and the beating sley 9 is fixed on the rocking shaft 8.

[0020] The main shaft 2 of the loom and the rocking shaft 8 are collinear, the center distance between the first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com