Elliptic gear-crank rocker weft insertion and beat-up mechanism of rapier loom

An oval gear, crank rocker technology, used in looms, textiles, textiles and papermaking, etc., can solve the problems of many hinge points, large accumulated errors, large processing accuracy, etc., to ensure accuracy, reduce errors, and facilitate processing and assembly. Effect

Inactive Publication Date: 2010-12-01

ZHEJIANG SCI-TECH UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the weft beating mechanisms of looms sold in the domestic market mainly include: conjugate cam beating mechanism, this type of mechanism can easily meet the motion law required for weft beating, and can achieve a complete pause time of about 240°, but the cam profile The processing accuracy is quite high, and if there is an error, there will be an impact; the four-link beating-up mechanism, if a beating displacement of about 5mm is allowed, can achieve an "approximate pause" time of about 65°, and its performance is worse than that of the conjugate cam beating-up mechanism , mainly used for non-separate sleys; the six-link beating-up mechanism, if a beating displacement of about 5mm is allowed, can achieve an "approximate pause" time of about 120°, and its performance is better than that of the four-link beating-up mechanism, but It is worse than the conjugate cam beat-up mechanism. In addition, the mechanism has more hinge points and the cumulative error is large, so the machining accuracy is required to be greater than that of the four-bar linkage beat-up mechanism.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

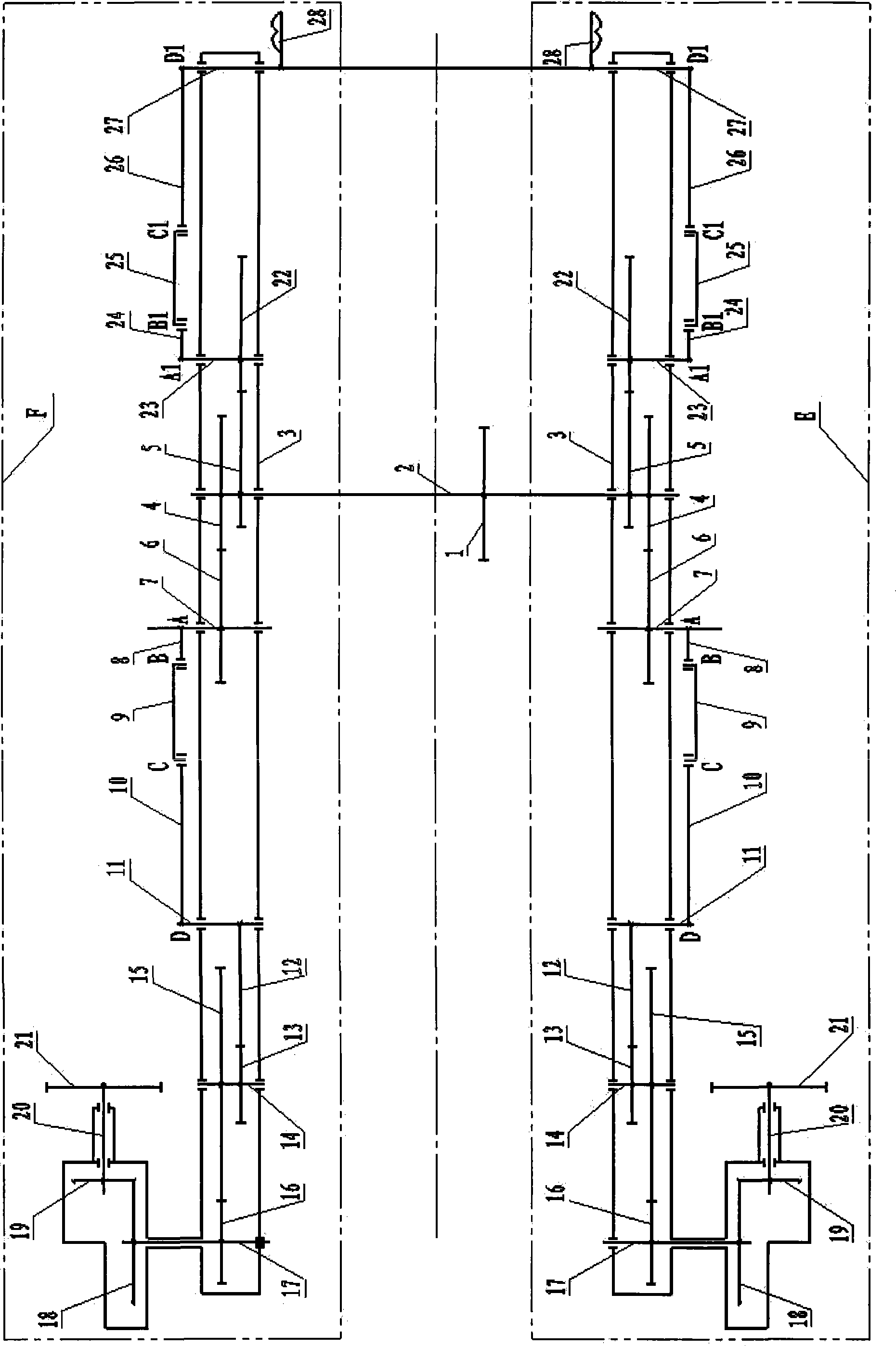

The invention discloses weft insertion and beating mechanisms for a rapier loom with elliptic gears and crank rockers. Two sides of a main shaft of the rapier loom are provided with a set of same weft insertion and beating mechanisms respectively. In each set of the mechanisms, the main shaft is provided with two pairs of the elliptic gears, wherein one pair of the elliptic gears transmits powerto a weft insertion rapier head through a crank rocker, two pairs of cylindrical gears, a pair of cone gears and a rapier wheel to form a weft insertion mechanism, so as to finish motions of conveying and receiving wefts, and achieve 'relay weft insertion' through making initial phase angles of the elliptic gears in the weft insertion mechanism at the left and the righ sides of the rapier loom different; and the acceleration rule of the rapier head is realized by 'isosceles trapezoid', and tension of wefts is reduced. The other pair of the elliptic gears transmits power to a weft beating reedthrough the crank rocker to form a weft beating mechanism, so as to finish weft beating motion, and achieve that a sley has about 200 degrees of full dwell time at a back center position. The gears in the mechanisms are arranged in the same gear box, are more convenient to process and assemble than conjugated cams, and are easy to ensure precision.

Description

Oval gear-crank rocker weft insertion and beating mechanism for rapier looms technical field The invention relates to a weft insertion mechanism and a weft beating mechanism of a rapier loom, in particular to an oval gear-crank rocker weft insertion and beating mechanism of a rapier loom. Background technique The function of the weft insertion mechanism is to convert the uniform rotational motion of the main shaft of the rapier loom into the non-uniform regular linear reciprocating movement of the rapier head. At present, the weft insertion mechanisms of rapier looms sold in the domestic market mainly include: conjugate cam weft insertion mechanisms. The error will produce impact; the variable pitch screw drive weft insertion mechanism, the variable pitch screw pair of this type of mechanism is difficult to process; the plane six-link weft feeding and four-link weft connecting mechanism can conveniently realize "relay" weft insertion, but its introduction The design flexi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D03D47/27D03D47/12

CPCD03D47/271D03D47/275

Inventor 陈建能徐宾顾叶琴赵雄

Owner ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com