Parallel flow heat exchanger and wing band structure thereof

A technology of heat exchangers and fin strips, applied in the field of air conditioning, can solve problems such as poor drainage of condensed water and easy freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

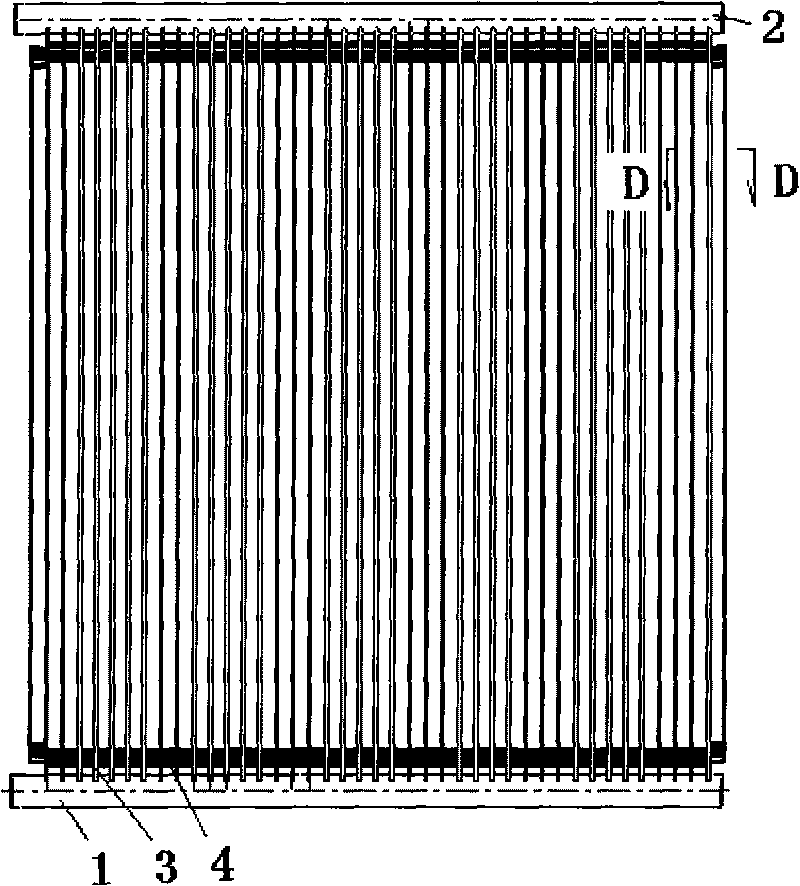

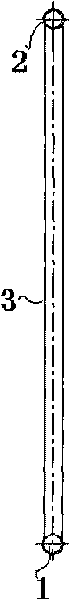

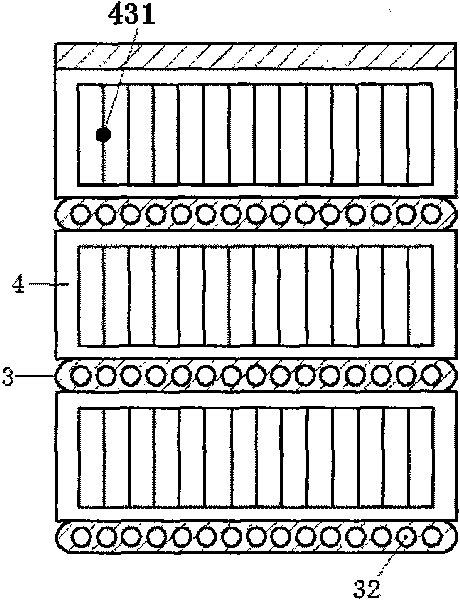

[0038] see Figure 1-6 As shown, a parallel flow heat exchanger and its fin structure, including a first header 1, a second header 2, and a flat heat exchanger installed between the two headers to allow refrigerant to pass through The tube 3 and the fin strip 4 installed between the flat heat exchange tubes, the fin strip is made into a corrugated structure with a crest section 41, a straight section section 43, and a wave trough section 42; each of the fin strips The straight sections are all provided with windows 4311 for ventilation, forming a louver section 431 structure, wherein,

[0039] The two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com