High-pressure heavy-calibre tapping machine with external independent adjustable pressure balance system

A drilling machine and large-diameter technology, applied in the direction of mechanical equipment, pipes/pipe joints/fittings, pipe components, etc., can solve problems such as unstable work, blockage of the balance system, major accidents, etc., to prevent misoperation accidents, safety The effect of sexual enhancement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

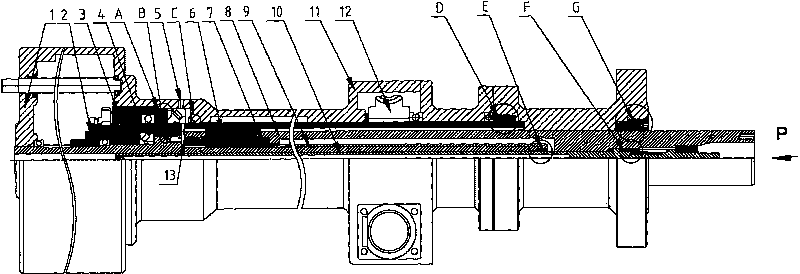

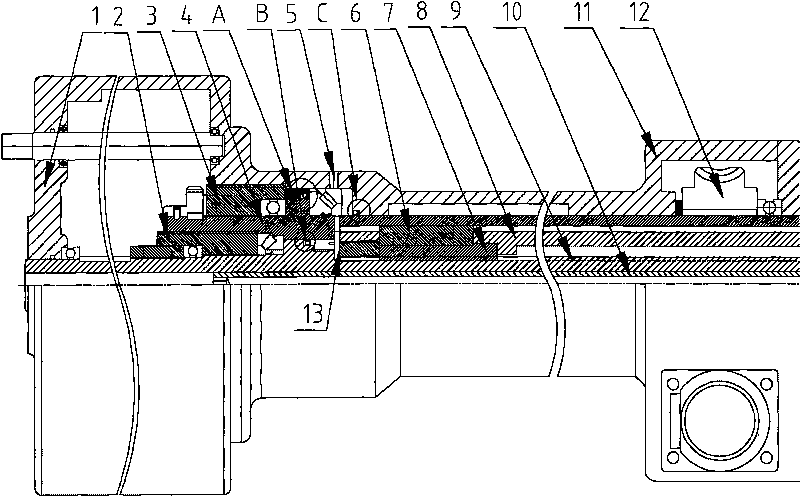

[0026] Its main transmission mode etc. of the drilling machine device of the present invention are all identical with the prior art. Not including the feed gearbox 1; the shell of the drilling machine 11; the flange; the scale drive rod 10; the rotating drive shaft 4 driven by the worm gear 12 through the key, and the rotating drive shaft is driven by the key 6 of the drill rod of the drilling machine Hole drilling machine drill rod 8, the feed screw 9 is connected to the feed screw lock nut 7 in the hole drill drill rod, and the inner hole of the feed screw is sleeved on the scale drive rod 10; At the rear end, a rotary drive shaft lock nut 3 is arranged between the outer diameter of the rotary drive shaft and the shell of the drilling machine, the inner diameter of the rotary drive shaft is screwed with the feed screw lock nut, and the feed screw lock nut 2 is set on the The outer diameter of the feed screw is fine.

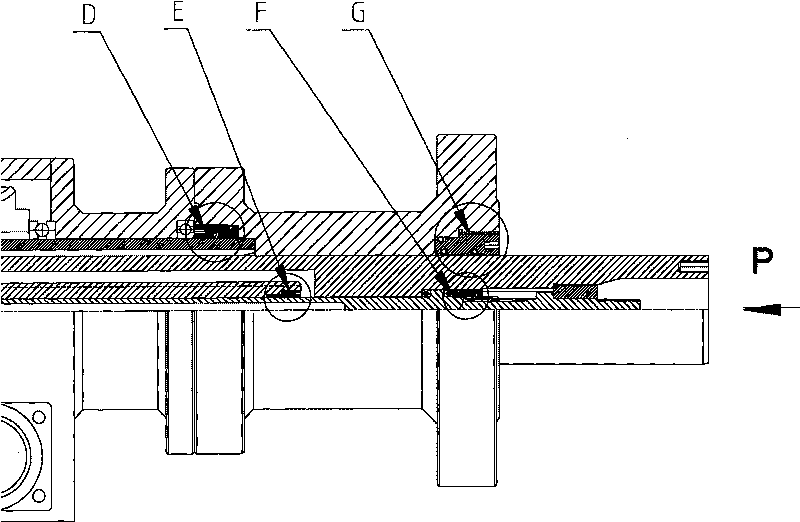

[0027] The external independent adjustable backup pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com