Anchor bolt

A technology of anchor bolts and bolt heads, which is applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of troublesome processing and production, many components, complex structure, etc., and achieve the effect of simple processing and production, easy processing and manufacturing, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

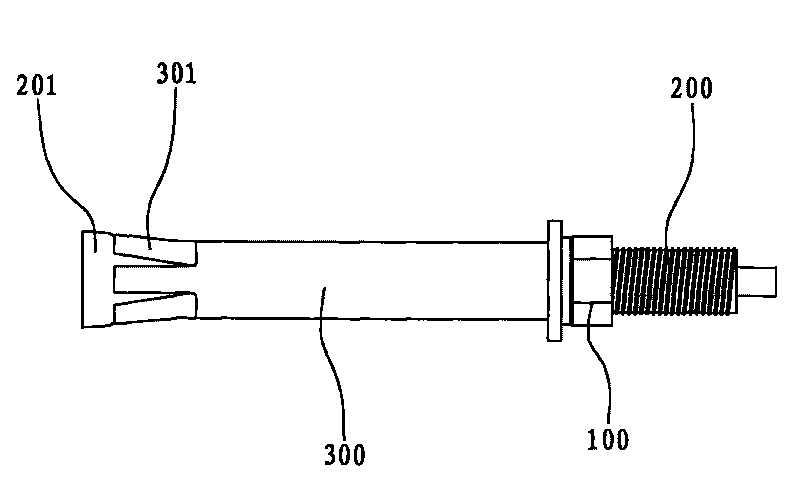

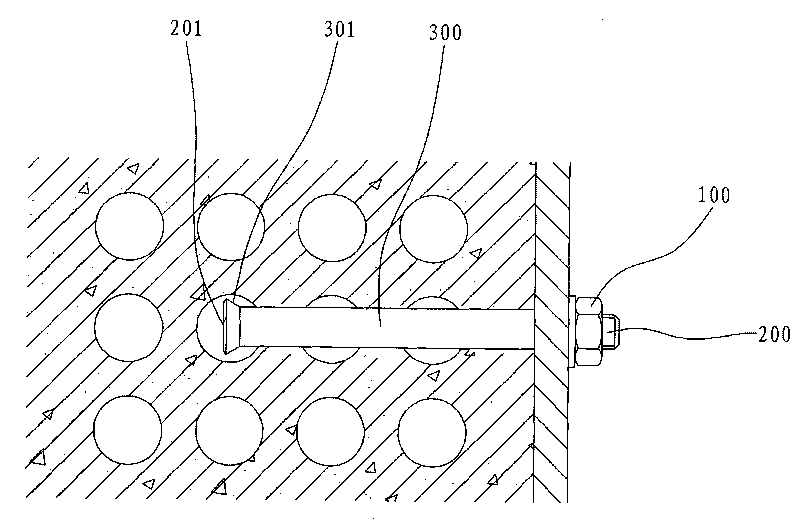

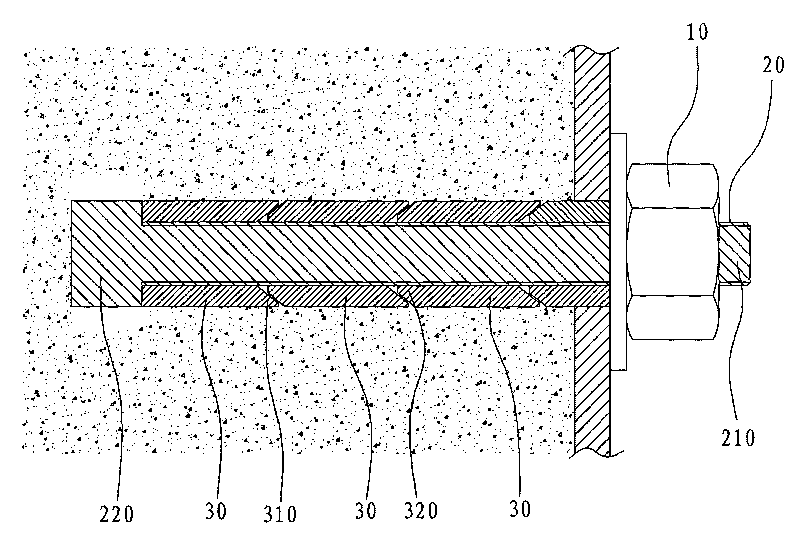

[0047] like image 3 and Figure 4 Shown is a preferred embodiment of the present invention, which consists of a nut 1, a screw 2 and an expansion member 3.

[0048] The screw 2 has a threaded section 21 at its outer end and a screw head 22 at its inner end. The bolt head 22 can be integrally formed on the screw rod 2 , or can be formed separately from the screw rod 2 and then fixed on the screw rod 2 .

[0049] The expansion part 3 is in the shape of a tube, and there are several rows of expansion holes 31 that guide the expansion part 3 to expand and deform in the radial direction of the tube wall. In this embodiment, the expansion holes 31 are axially long holes. Expansion sheets 32 are formed between adjacent expansion holes 31 in each row. In order to facilitate deformation of the expansion sheets 32 , small holes 33 are formed on the expansion sheets 32 , and flaring openings 36 are formed at both ends of the expansion holes 31 . The expansion member 3 is sheathed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com