Position controller of electronic throttle body

An electronic throttle body and controller technology, which is applied in electrical control, engine control, fuel injection control, etc., can solve the problems of troublesome hardware circuit modification, difficult to implement, and complicated electronic throttle body assembly, etc., to achieve the direction and position Easy to control, cleverly conceived, precise control of the effect of door position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

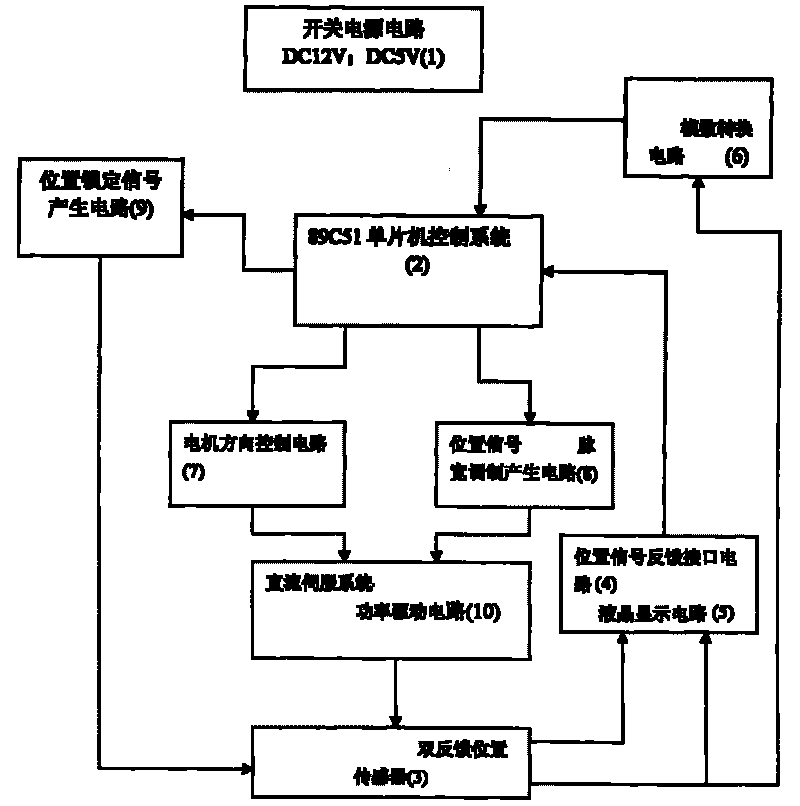

[0023] figure 1 As shown, an electronic throttle body position controller is mainly composed of DC12V and DC5V switching power supply circuits 1, 89C51 single-chip control system 2, liquid crystal display circuit 5, motor direction control circuit 7, position signal pulse width modulation generation circuit 8, position sensor, an analog-to-digital conversion circuit 6, a position signal feedback interface circuit 4, a DC servo system power drive circuit 10 and a position locking signal generation circuit 9. The liquid crystal display circuit 5, the motor direction control circuit 7 and the position signal pulse width modulation generation circuit 8 are all connected with the 89C51 single-chip microcomputer control system 2. The output signal of the double feedback position sensor is input to the single-chip microcomputer through the analog-to-digital conversion circuit.

[0024] The position sensor adopts the (non-contact) dual feedback position sensor 3 modeled as infineon49...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com