Lactobacillus acidophilus freeze-drying composite protectant and application method thereof

A technology of Lactobacillus acidophilus and protective agent, which is applied in the field of Lactobacillus acidophilus freeze-dried composite protective agent, can solve the problems of not meeting the requirements of long-term storage of Lactobacillus acidophilus, the survival rate is reduced, and the survival rate is not easy to reduce. , the effect of high survival rate and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

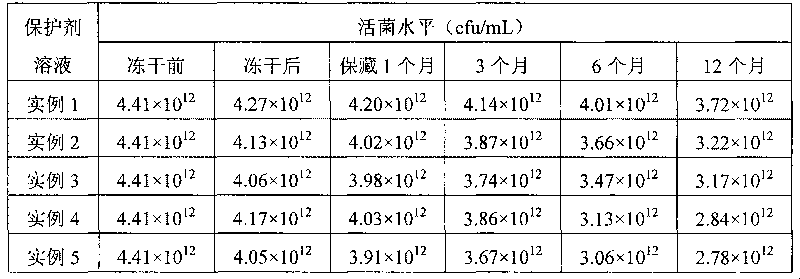

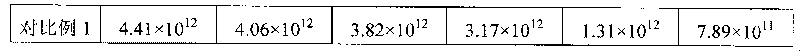

Examples

example 1

[0016] Compound protective agent solution formula: skimmed milk powder 10%, lactose 10%, glycerin 0.5%, sodium glutamate 2%, vitamin C 0.2%. All the above are mass fractions after being formulated into aqueous solutions, the same below.

[0017] Wherein, the skimmed milk powder is commercially available New Zealand skimmed milk powder, and the weight percent content is: 0.8% of fat, 33.4% of protein, 54.1% of lactose, and 3.5% of water. The skimmed milk powder used below is the same as above.

[0018] Composite protectant solution preparation

[0019] ① Weigh sodium glutamate and vitamin C according to the amount, add some distilled water to dissolve, and filter to sterilize;

[0020] ② Weigh skimmed milk powder, lactose and glycerin, add part of distilled water, heat to dissolve and mix well, and cool to room temperature;

[0021] ③Adjust the pH value to about 7.0 with NaOH solution;

[0022] ④ Sterilize at 115°C for 10 minutes and cool to room temperature;

[0023] ⑤ Ad...

example 2

[0025] Compound protective agent solution formula: skimmed milk powder 10%, lactose 10%, glycerin 0.3%, sodium glutamate 2%, vitamin C 0.2%, distilled water 77.5%.

[0026] Prepare composite protective agent solution according to the method of example 1.

example 3

[0028] Compound protective agent solution formula: skimmed milk powder 10%, lactose 12%, glycerin 0.6%, sodium glutamate 2.5%, vitamin C 0.2%, distilled water 74.7%.

[0029] Prepare composite protective agent solution according to the method of example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com