Steel structured wide-bay energy-saving residential building with gypsum walls and on-site layering and sectioning manufacturing method

A technology for residential construction and large bays, which is applied to residential buildings, buildings, building components, etc., to achieve the effects of enhancing building energy-saving effects, good seismic performance, and saving clay resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

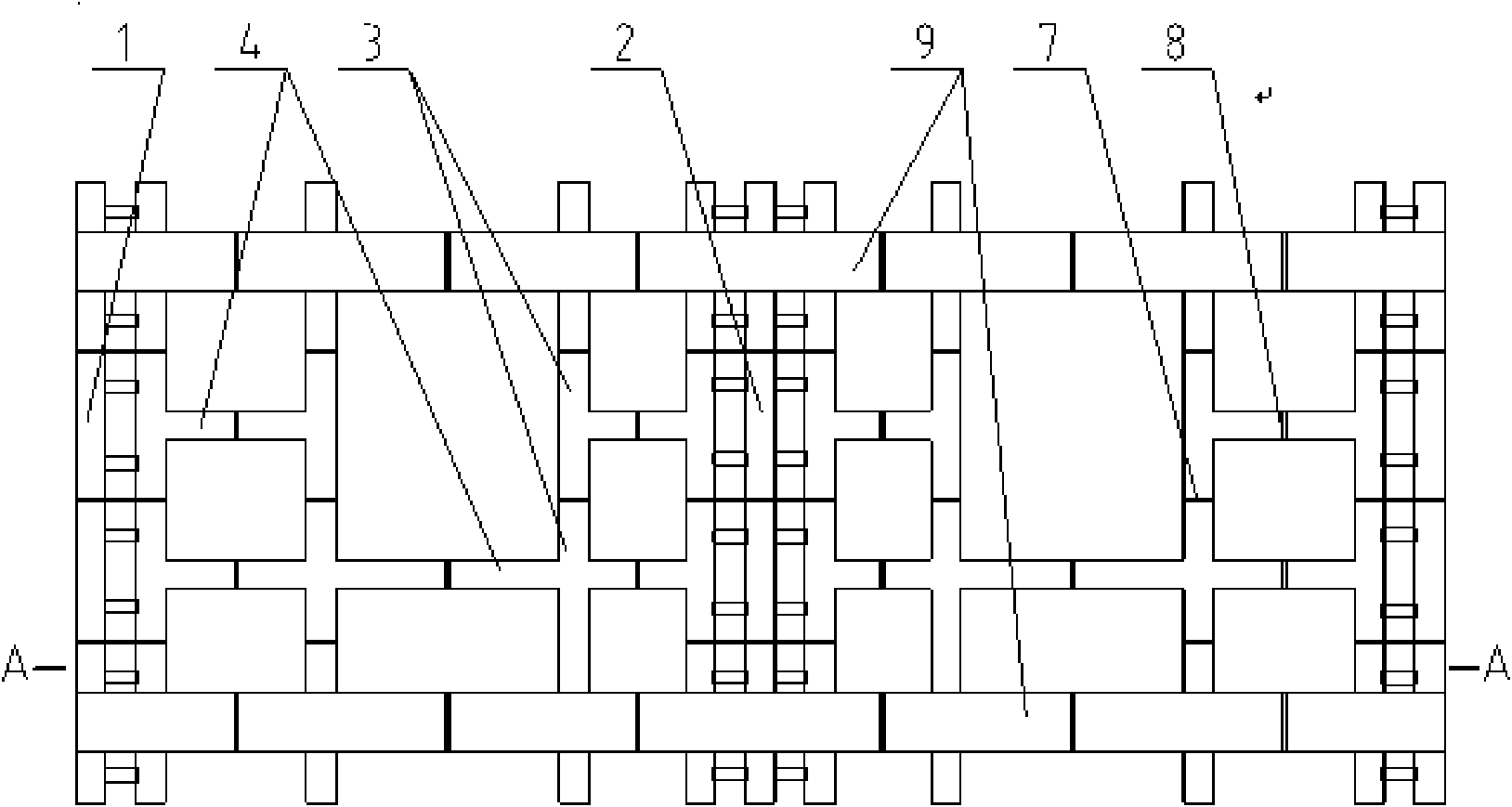

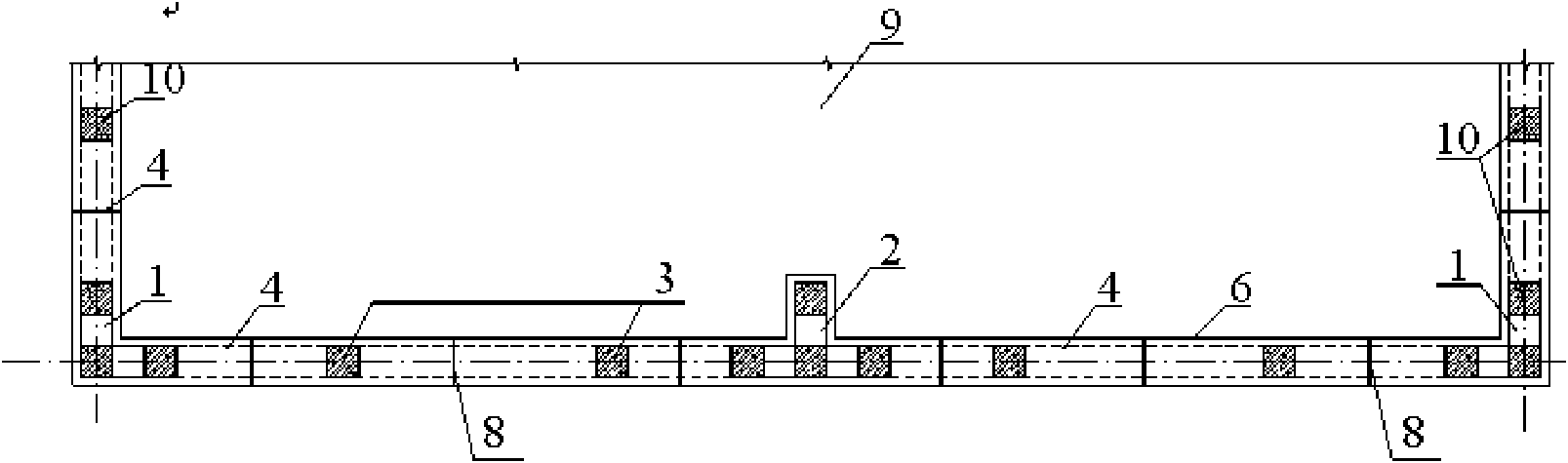

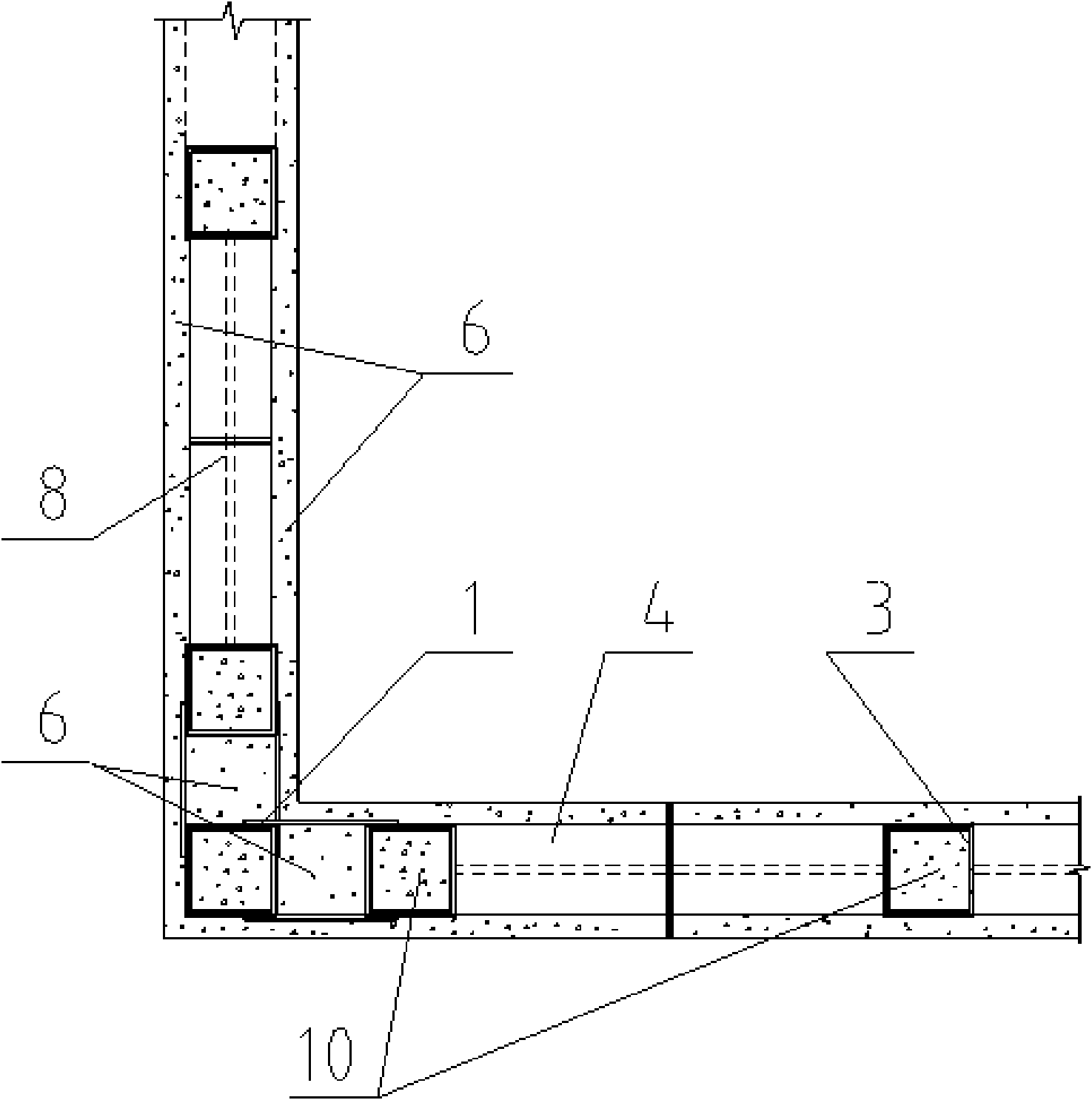

[0023] Embodiment of the present invention: When making a large-bay residential building with a room width of ≤12 meters, a depth of ≤9 meters, and a number of floors n≤15, the energy-saving house with a steel structure gypsum wall of the present invention is adopted. The building is manufactured in layers and sections on site. The steel grid frame is used as the skeleton of the exterior wall or load-bearing wall of the residential building. The steel grid frame is made of pre-welded and formed steel components in the factory, which are spliced and connected into a network on site. grid-shaped steel grid frame, and the on-site connection between the steel components and steel components is carried out by high-strength bolts. When splicing the steel grid frame, each floor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap