Construction control device for pedestal pre-embedded steel plates of pre-stressed concrete box girder

A technology of pre-embedded steel plates and support steel plates, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems that the construction site is difficult to meet the construction progress requirements, affects the quality of the box girder, and is prone to loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

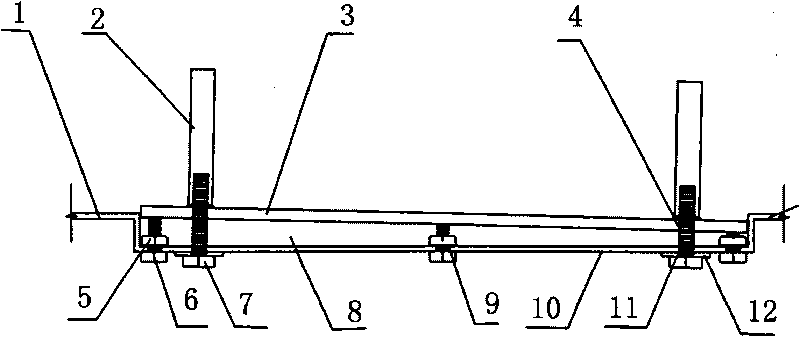

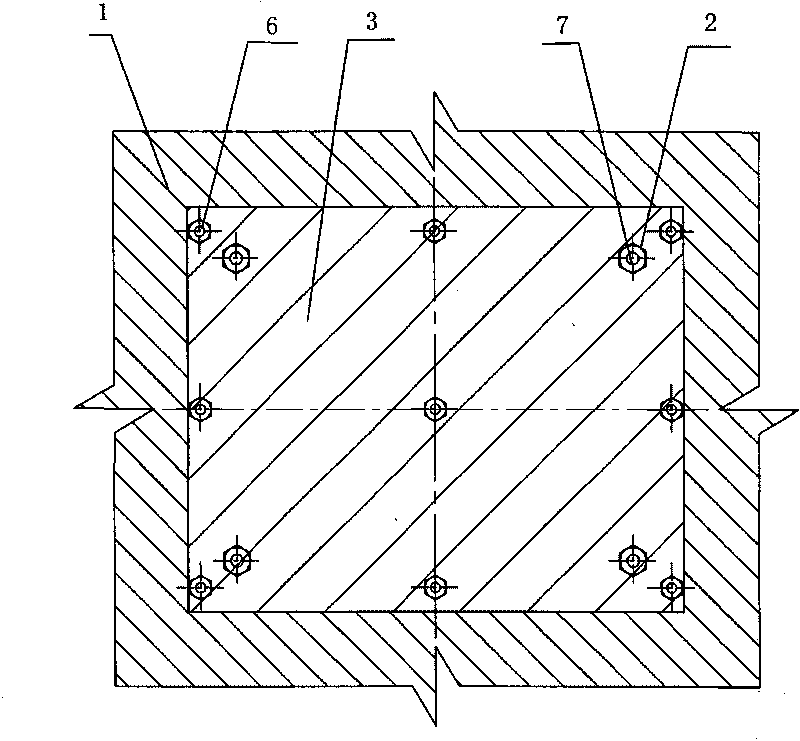

[0011] The present invention comprises basin-shaped box girder bottom mold support steel plate 1, on each of the four corners of the groove bottom plate 12 of box girder bottom mold support steel plate 1, an upper limit hole 11 is processed, and on the box girder bottom mold support steel plate A total of nine lower limit holes 9 in three rows and three columns are evenly processed on the groove bottom plate 12 of 1, and a positioning hole is fixed on the upper surface of the groove bottom plate 12 of the box girder bottom mold support steel plate 1 and above each lower limit hole 9. The nut 5, the support pre-embedded steel plate 3 with the same cross-sectional size as the groove bottom plate 12 of the box girder bottom form support steel plate 1 is placed in the groove 8 of the box girder bottom form support steel plate 1, and is embedded in the support On the steel plate 3, a pre-embedded sleeve hole 4 is processed at the position corresponding to the upper limit hole 11 of ...

Embodiment 2

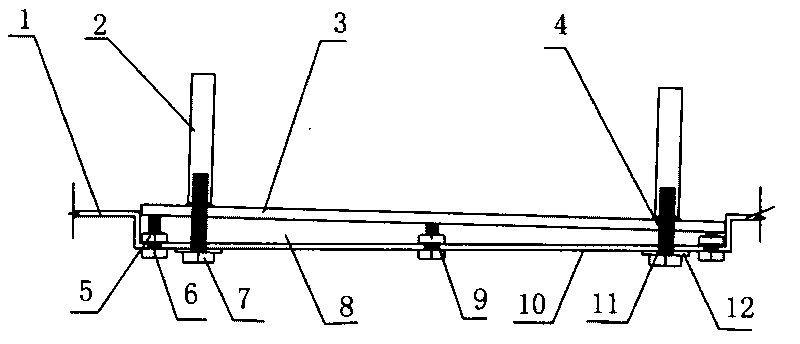

[0014] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is:

[0015] Four rows and five rows of nine lower limit holes 9 are evenly processed on the groove bottom plate 12 of the box girder bottom mold support steel plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com