Antiscaling compound and method for preventing and removing scale

An anti-scaling and particle technology, used in complex/solubilizer treatment, boiler cleaning devices, etc., can solve problems such as inconvenience in long-term use, neglect of scale removal, and failure to solve the problem of automatic cleaning of scale on metal surfaces, reducing boilers. The probability of scaling, reducing the concentration of scaling ions, and facilitating the effect of heterogeneous nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

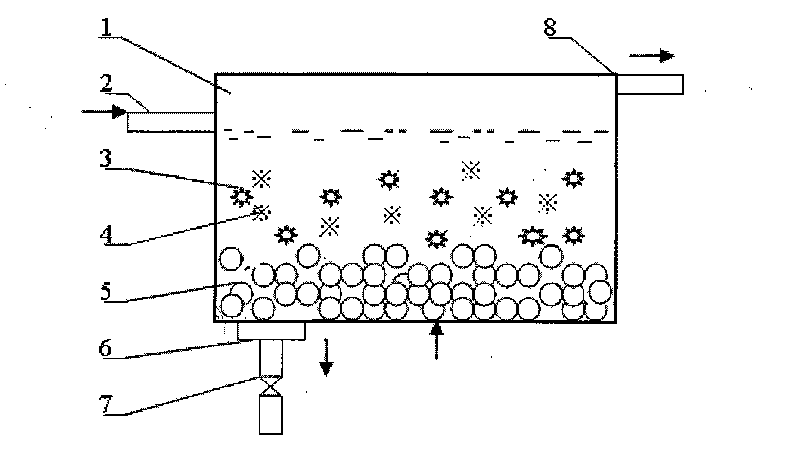

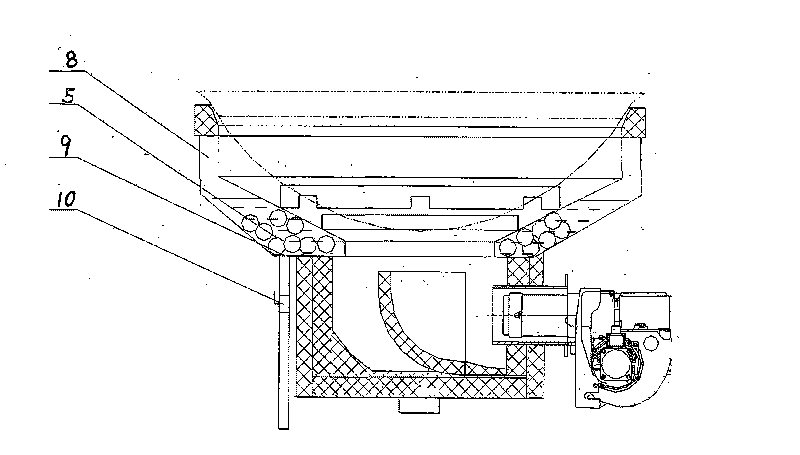

[0023] The invention utilizes an anti-scaling substance to prevent the formation of scale on the inner wall of the container or the inner wall of the water system. The anti-scaling substance consists of the following components: 20% to 50% of natural zeolite, titanium oxide TiO 2 5%~20%, vanadium oxide V 2 o 5 10%~40%, silicon oxide SiO 2 20% to 40%, NdFeB neodymium iron boron 5% to 20%; the anti-scaling substance is a collection of regular or irregular solid fine particles or a collection of solid porous particles; the average diameter of the anti-scaling fine particles is 0.5 mm ~ 15mm; when the average diameter of the anti-fouling particles is greater than 15mm, porous particles are used, and the pore diameter of the particles is greater than 20 μm and penetrates the particles; the density of the anti-fouling matter is 1.2g / cm 3 ~5g / cm 3 .

[0024] In the present invention, the anti-scaling substance is freely placed in the water of the heating water jacket of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com