Intermittent particulate material feeding device

An intermittent, powder technology, applied in presses, manufacturing tools, etc., can solve the problems of high price, low production efficiency, complex structure, etc., and achieve the effect of accurate volume guarantee, production quality assurance and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

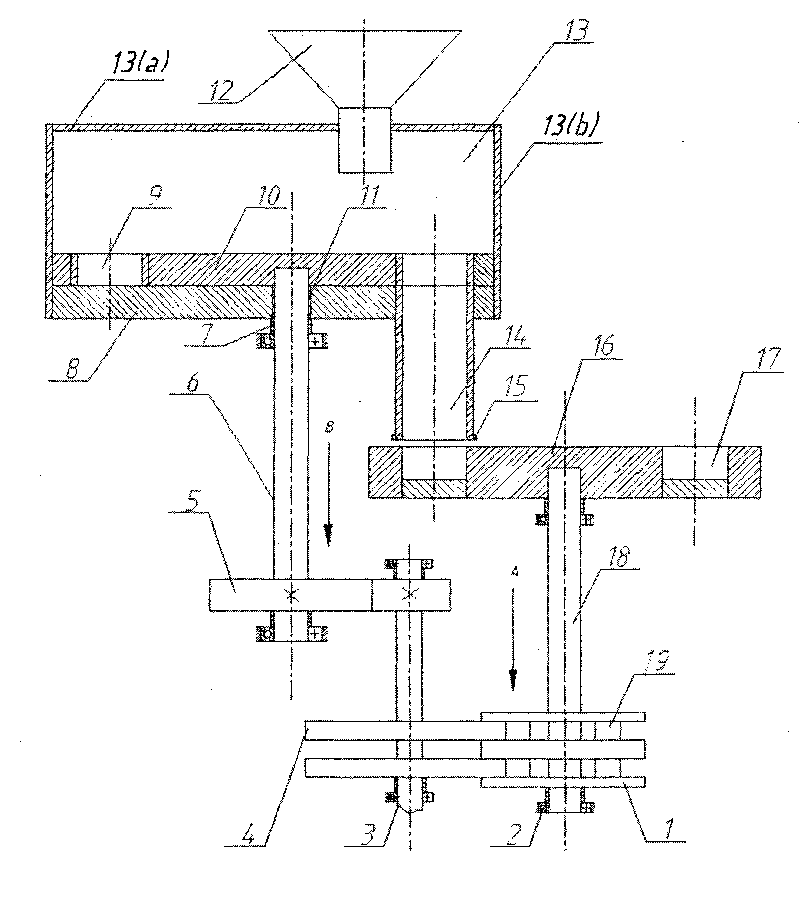

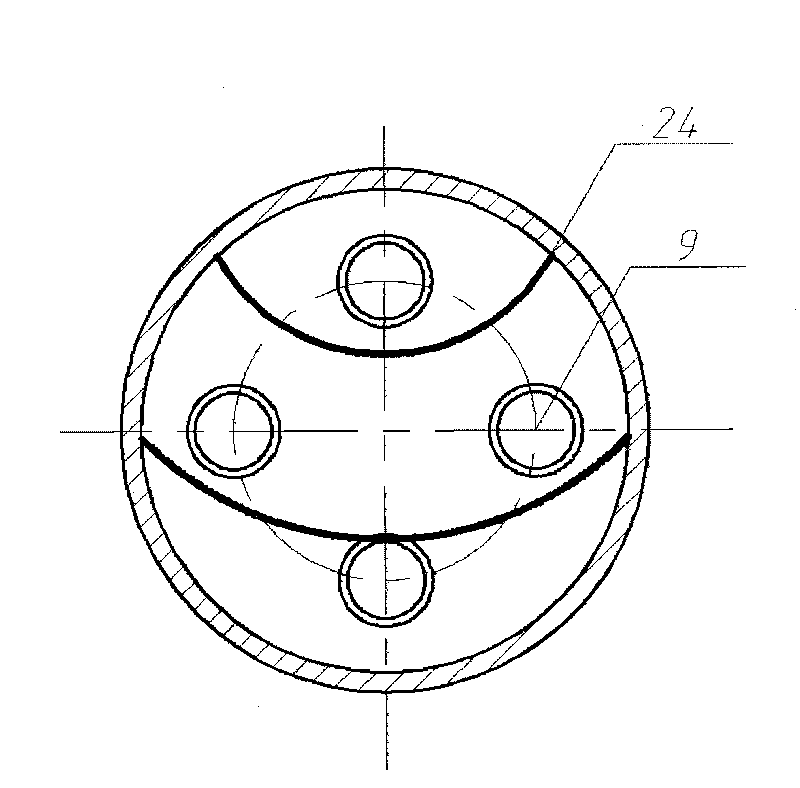

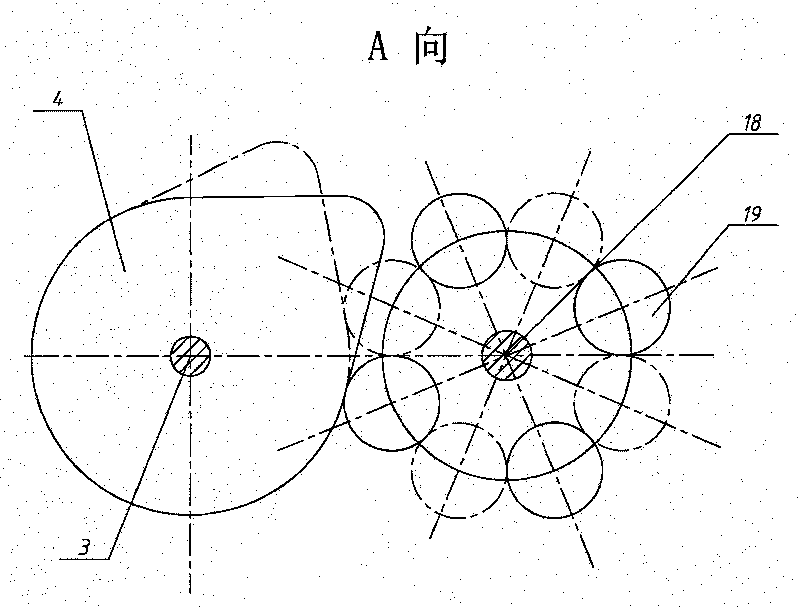

[0017] see figure 1 , 2 , 3, 4, this intermittent powder feeding device includes a turntable cup feeding mechanism 13, an incomplete gear 5, a parallel indexing cam 4, a rotary table 17, and connecting shafts 3, 6, 18, etc. Its characteristics are: the incomplete gear 5 and the driving wheel 5 (a) of the parallel indexing cam 4 are fixedly connected by the same shaft 3 (driving shaft), and the driven wheel 5 (b) of the incomplete gear 5 and the turntable container supply the material The upper turntable 10 of the mechanism 13 is fixedly connected with the same shaft 6, and the driven wheel 1 of the parallel indexing cam 4 and the rotary table 16 are fixedly connected with the same shaft 18; in this way, during the operation of the machine, the driving shaft 3 is not fully driven at the same time. The gear 5 and the parallel indexing cam 4 rotate intermittently, so that the turntable cup feeding mechanism 13 and the rotary table 17 realize intermittent rotation.

[0018] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com