Wear compensation device for buffing wheel of buffing machine

A technology of wear compensation and grinding wheel, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., which can solve problems such as poor control, unstable quality, and unstable workpiece surface, so as to avoid the difference , avoid uncertainty, consistent polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

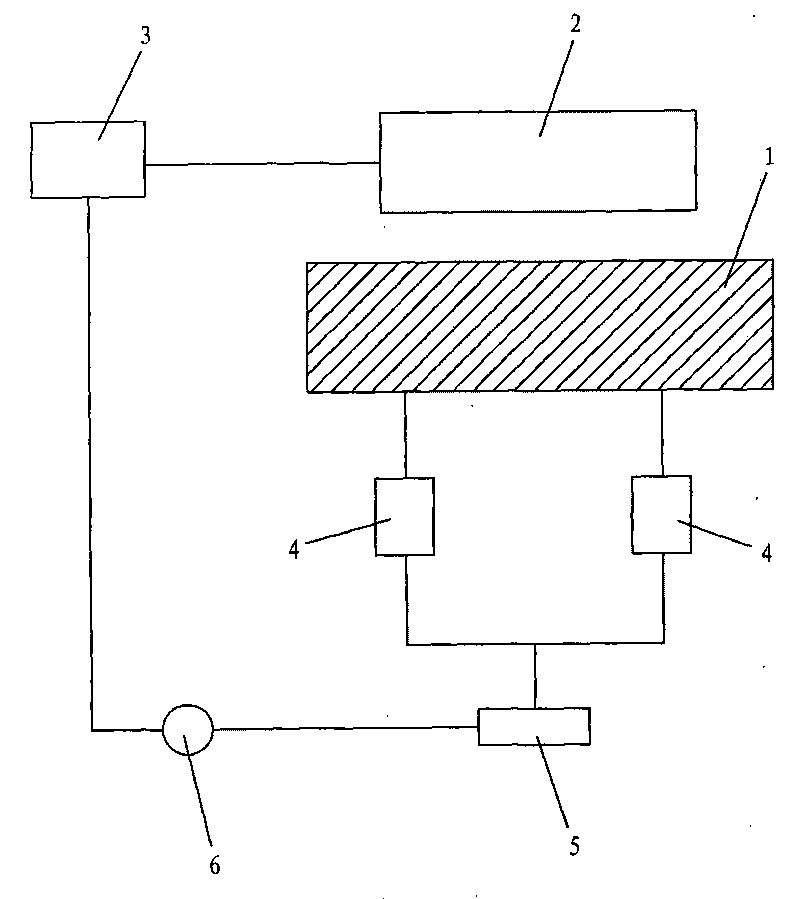

[0009] refer to figure 1 , a grinding wheel wear compensation device for a polishing machine of the present invention, comprising a grinding platform 1, a grinding wheel 2 positioned above the grinding platform 1, a motor 3 for driving the grinding wheel 2 to rotate, and a lifting grinding wheel is provided below the grinding platform 1 The lifting mechanism 4 of the platform 1 is connected with a drive motor 5 , the motor 3 is connected with a current detection signal control device 6 , and the current detection signal control device 6 is connected with the drive motor 5 .

[0010] The above technical solution can also have the following improvement: the grinding wheel 2 is a cloth wheel or other grinding wheels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com