Low-temperature ultrahigh-pressure continuous sterilization method for liquid milk

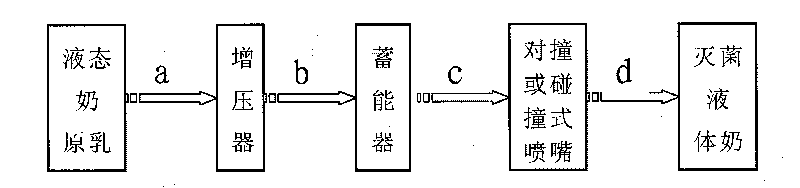

A low-temperature, ultra-high-pressure, sterilization method, which is applied in the direction of milk preservation, dairy products, applications, etc., can solve the problems of high loss of nutrients, short pasteurization shelf life, high energy consumption of thermal sterilization, etc., to achieve easy digestion and absorption, Efficient continuous production process, easy connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

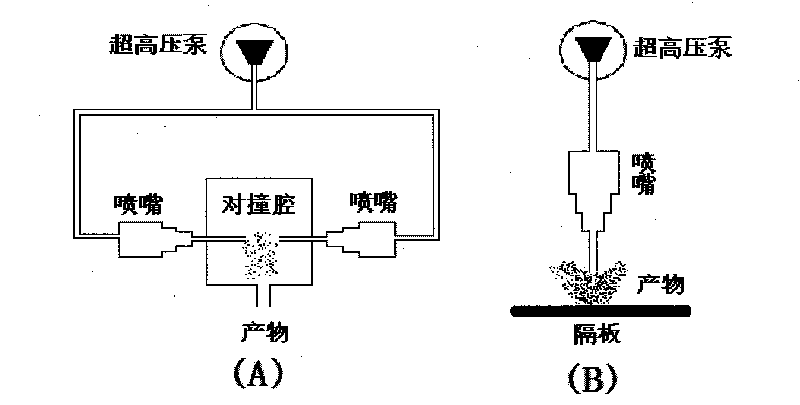

Embodiment 1

[0032] The pressure parameter of the cold chain liquid milk is 200MPa, and the nozzle is a coaxial and equivalent collision type ultra-high pressure water jet system. The supersonic jet will collide strongly to kill microorganisms, inactivate enzymes and crush milk fat globules. The refrigerated shelf life can reach 90 days; the total number of colonies is changed from 1.96×10 5 / ml down to 3×10 2 / ml, the sterilization rate reaches 99.85% (see image 3 ); the sterilization temperature is 49°C (see Figure 4 ); detected by the JL-1177 laser particle size tester, the results are shown in Figure 5 , Figure 6 .

Embodiment 2

[0034] Similar to Implementation 1, the difference is that the pressure is 50MPa, and the nozzle is collision type. The refrigerated shelf life is more than 10 days; the total number of colonies is changed from 1.96×10 5 / ml down to 1.77×10 4 / ml, the sterilization rate reached 90.97% (see image 3 ); the sterilization temperature is 21°C (see Figure 4 ); detected by the JL-1177 laser particle size tester, the results are shown in Figure 5 , Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com