Process for producing high-strength cold rolled steel sheet with low yield strength and with less material quality fluctuation

A technology of cold-rolled steel sheet and manufacturing method, which is applied in the field of manufacturing high-strength cold-rolled steel sheet for stamping and forming, can solve the problems of trunk lid appearance, design damage, surface deformation, etc., and achieve excellent surface deformation resistance and Concave resistance, small material change, low YP effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

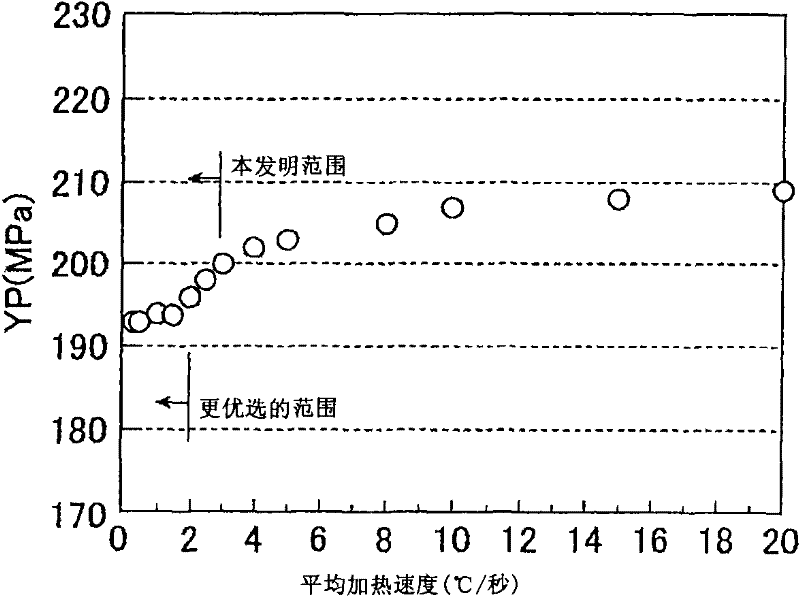

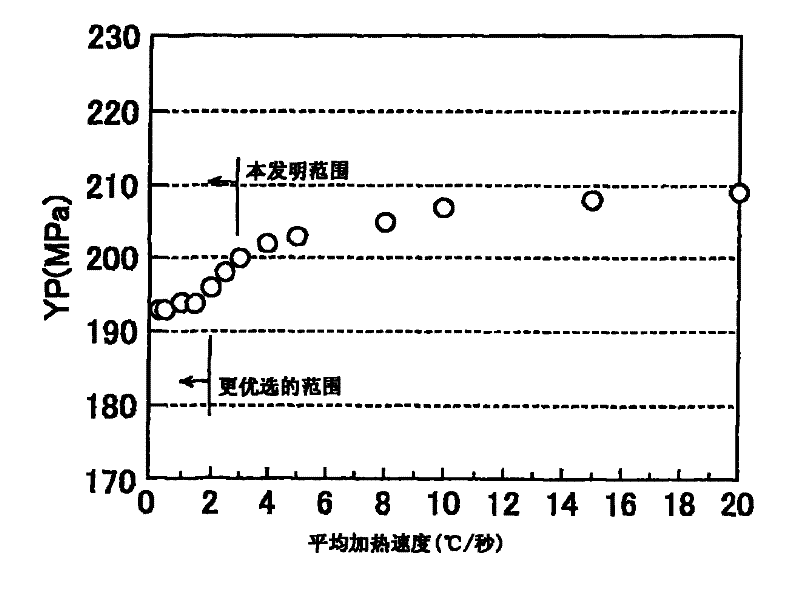

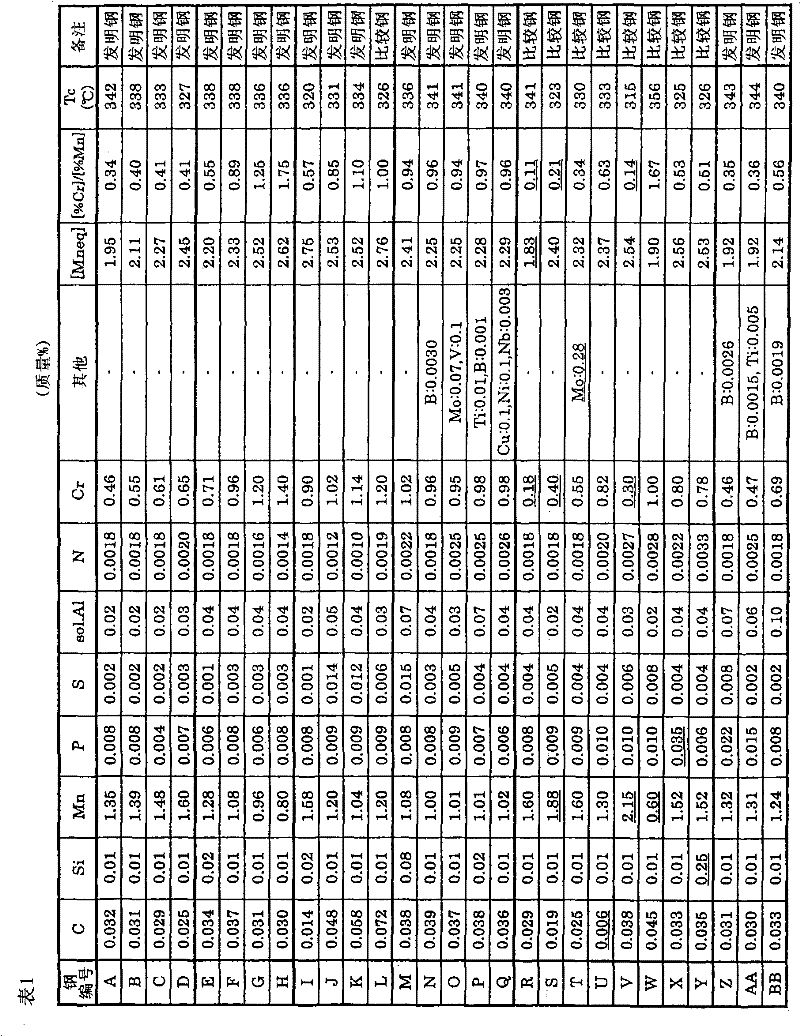

[0080] Steels of steel numbers A to BB shown in Table 1 were melted, and then continuously cast into billets with a thickness of 230 mm. After heating the billet to 1180-1250°C, finish rolling at 830°C (steel numbers A~D, I, R~V, X~BB) and 880°C (steel numbers E~H, J~Q, W) Hot rolling is carried out at high temperature. Then, cooling is performed at an average cooling rate of 20°C / sec, and coiling is performed at a coiling temperature of 540 to 640°C. The obtained hot-rolled sheet was pickled and then cold-rolled at a rolling ratio of 67 to 78% to produce a cold-rolled sheet with a thickness of 0.75 mm. The obtained cold-rolled sheet, the average heating rate in the temperature range of 680 to 740°C shown in Table 2 and 3, the annealing temperature, the primary average cooling rate in the temperature range from the annealing temperature to 650°C, and the average cooling rate from 650°C to T C The average cooling rate of 2 times in the temperature range of ℃, from T C Annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com