Forming method and product thereof

A molding method and product technology, applied in thin material handling, adhesives, transportation and packaging, etc., can solve problems such as poor bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

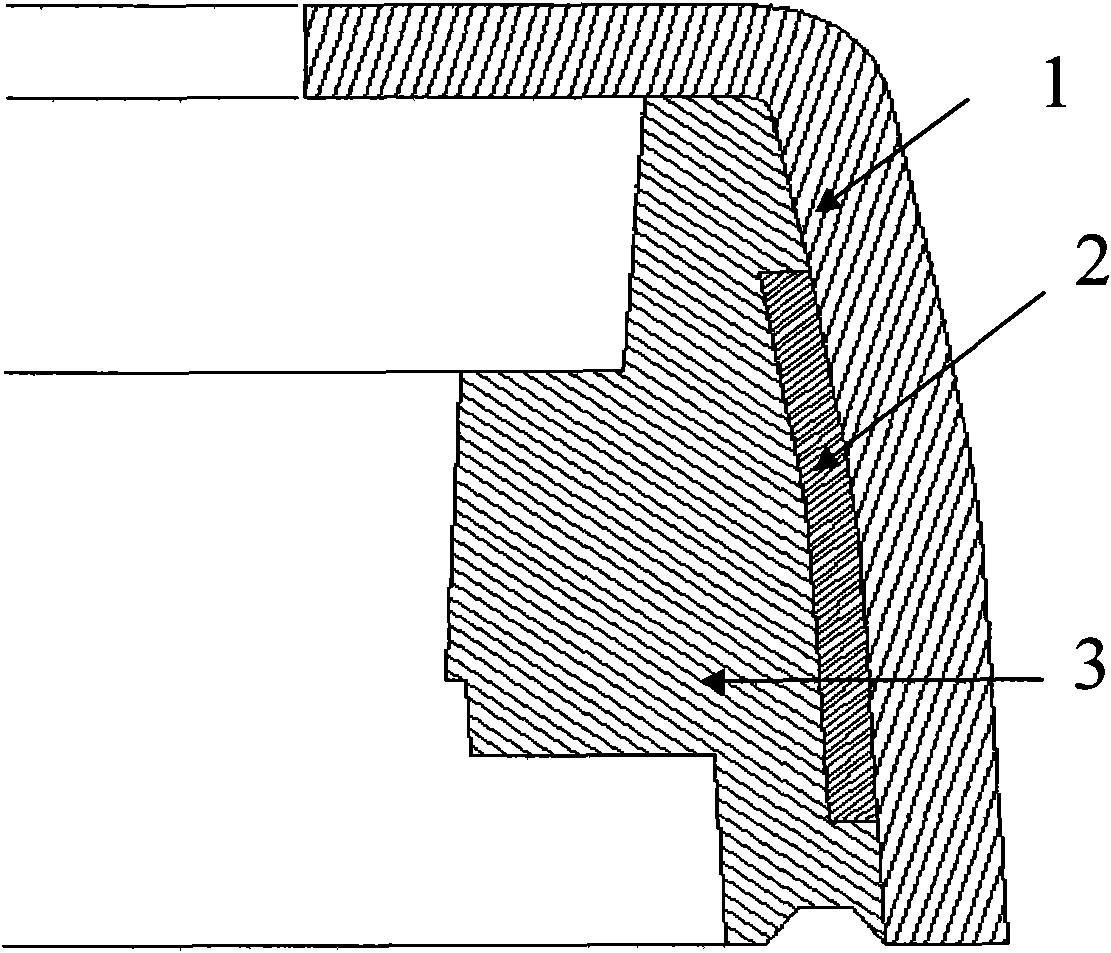

Image

Examples

Embodiment 1

[0029] According to the following method, an aluminum alloy plate metal part with a size of 100x100x2mm is molded with plastic.

[0030] Biting flowers on the aluminum alloy plate;

[0031] The aluminum alloy plate is heated to 120 degrees, and the hot melt adhesive (615ST product of 3M Company) is laminated on the aluminum alloy plate with a lamination roller, and the lamination time is 6 seconds. The thickness of the hot melt adhesive is 0.12mm.

[0032] Then put the aluminum alloy plate into the mold, under the temperature of 280 degrees Celsius, 1350kg / cm 2 Under pressure, the plastic raw material is injected onto the aluminum alloy plate.

[0033] Curing and forming. Product A is obtained.

Embodiment 2

[0035] According to the following method, an aluminum alloy plate-shaped metal part with a size of 50x50x2mm is molded with plastic.

[0036] Biting flowers on the aluminum alloy plate;

[0037] The aluminum alloy plate is heated to 120 degrees, and the hot melt adhesive (615ST product of 3M Company) is laminated on the aluminum alloy plate with a laminating roller. The lamination time is 6 seconds, and the thickness of the hot melt adhesive is 0.10mm.

[0038] Then put the aluminum alloy plate into the mold, under the temperature of 280 degrees Celsius, 1250kg / cm 2 Under pressure, the plastic raw material is injected onto the aluminum alloy plate.

[0039] Curing and forming. Product B is obtained.

Embodiment 3

[0041] According to the following method, an aluminum alloy plate metal part with a size of 100x100x2mm is molded with plastic.

[0042] The aluminum alloy plate is heated to 120 degrees, and the hot melt adhesive (615ST product of 3M Company) is laminated on the aluminum alloy plate with a lamination roller, and the lamination time is 6 seconds. The thickness of the hot melt adhesive is 0.12mm.

[0043] Then put the aluminum alloy plate into the mold, at a temperature of 285 degrees Celsius, 1350kg / cm 2 Under pressure, the plastic raw material is injected onto the aluminum alloy plate.

[0044] Curing and forming. Product C is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com