Industrial robot

A technology of industrial robots and motors, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as inability to properly correct deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

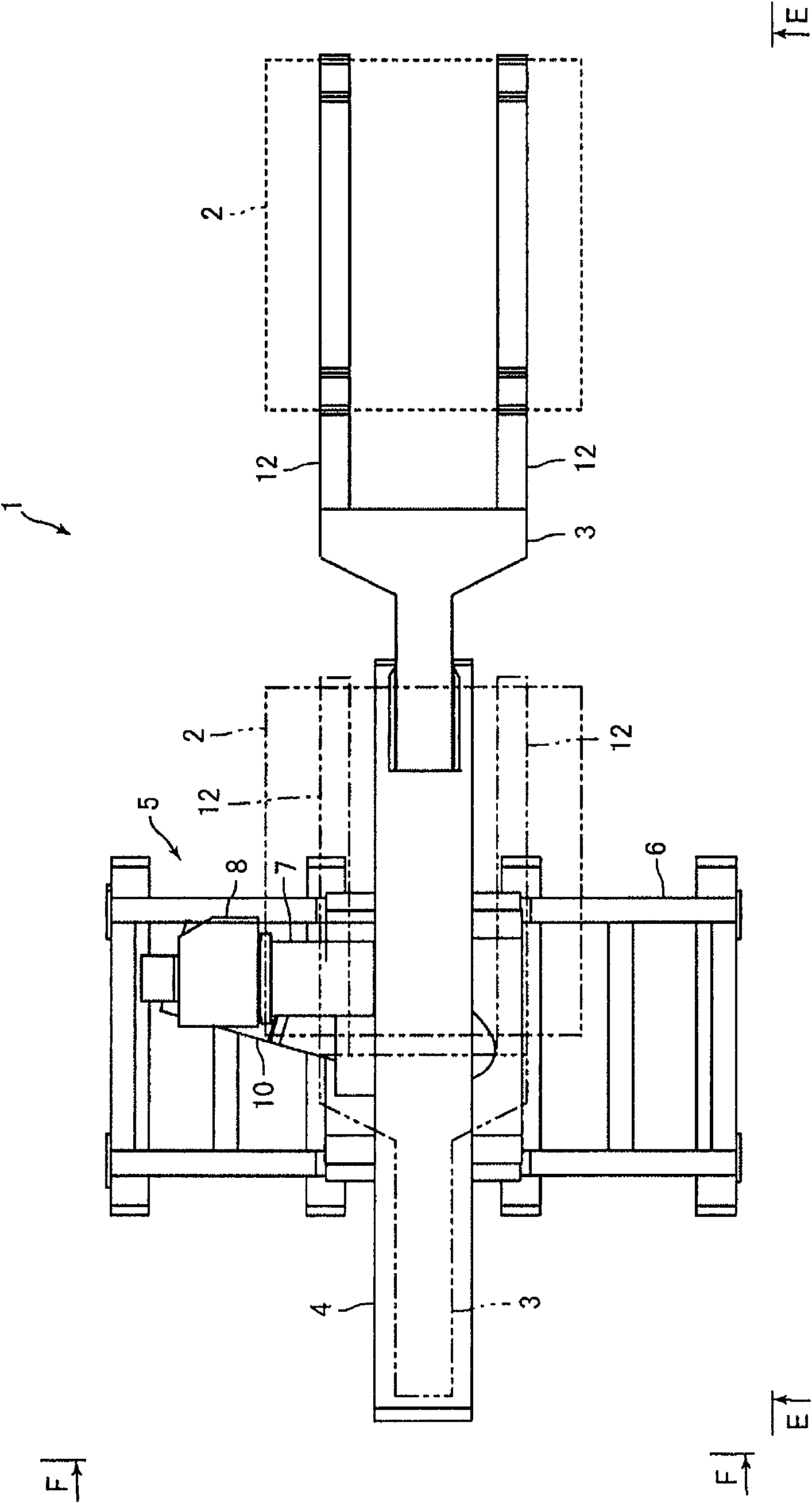

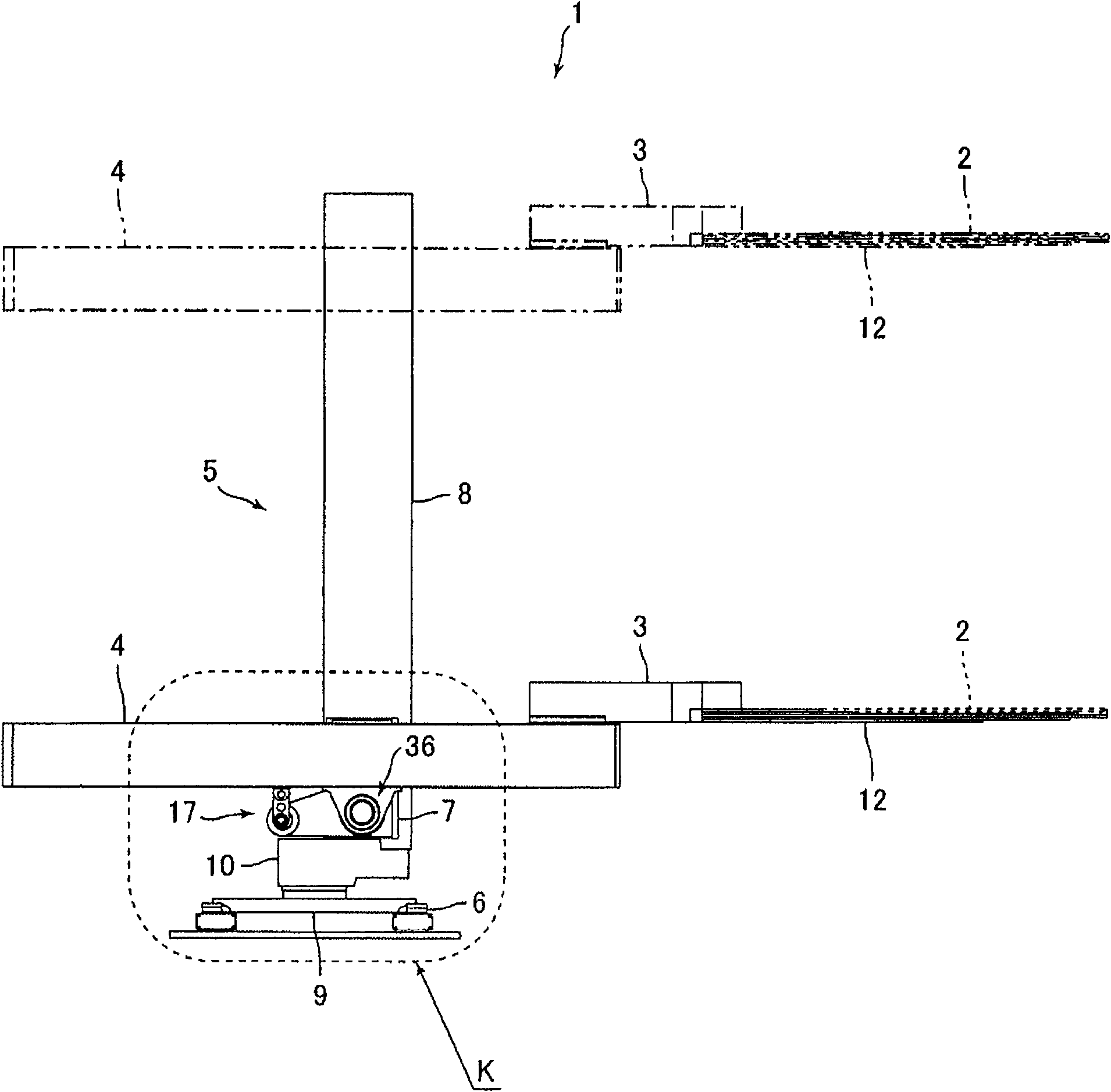

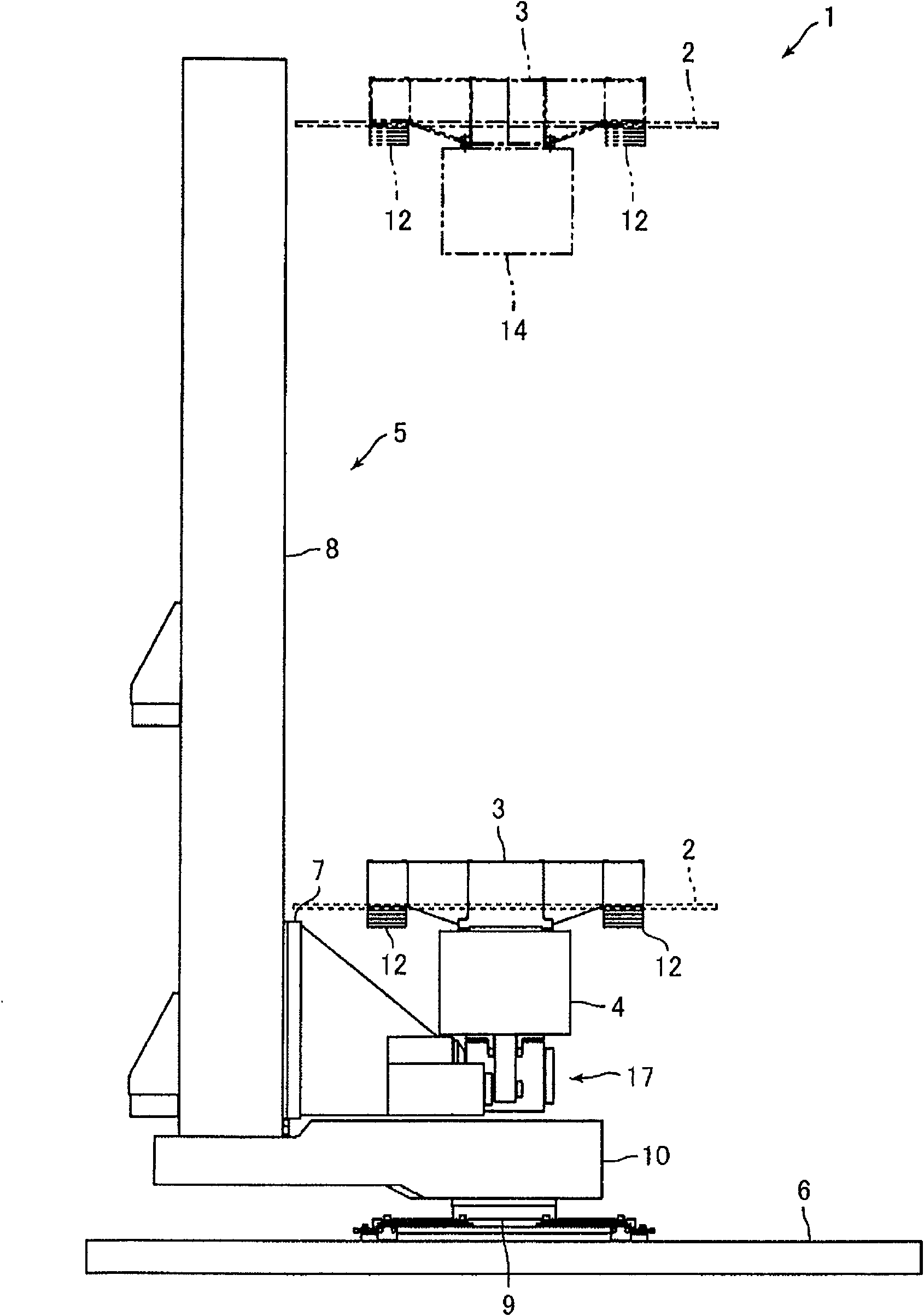

Image

Examples

other Embodiment approach

[0096] The above-described embodiment is an example of a more preferable embodiment of the present invention, but the present invention is not limited thereto, and various modifications can be made without changing the gist of the present invention.

[0097] In the above-described embodiment, the inclination correction motor 37 and the eccentric shaft 39 are mounted on the supporting member 7, the mounting member 41 is fixed on the bottom surface of the frame 27 of the linear drive unit 4, and the fulcrum portion 36 is formed between the linear drive unit 4 and the supporting member. 7 connections. In addition to this, for example, a structure may be adopted in which the inclination correction motor 37 and the eccentric shaft 39 are mounted on the linear drive unit 4, the mounting member 41 is fixed to the bottom surface of the hand 3, and the fulcrum portion 36 is formed on the linear drive unit. 4 and the link between the hand 3.

[0098] In the above-described embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com